- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

150

-

Marketing Type:

-

New Product

-

Cutting Accuracy(mm):

-

±0.1mm

-

Brand Name:

-

CHINSAIL

-

Voltage:

-

380V

-

Rated Power:

-

15KW, 20HP

-

Dimension(L*W*H):

-

3200*2200MM

-

Weight (KG):

-

5000 KG

-

Cutting metal thickness:

-

0-100mm

-

Continuous Working Pressure:

-

350-380mpa

-

Cutting accuracy:

-

±0.1mm

-

Power Requirement:

-

(415v/50hz), 380V/50HZ, ( 220v/60hz), 3 phase

-

linear guider:

-

imported from TAIWAN HIWIN

-

Pump type:

-

60000psi direct drive pump

-

Control accuracy:

-

±0.05mm

-

Max pressure:

-

60000psi

-

Certification:

-

CE

-

Control system:

-

5 axis

Quick Details

-

Place of Origin:

-

Shandong, China

-

Table Travel (X) (mm):

-

1500

-

Table Travel (Y) (mm):

-

3000

-

Table Travel (Z) (mm):

-

150

-

Marketing Type:

-

New Product

-

Cutting Accuracy(mm):

-

±0.1mm

-

Brand Name:

-

CHINSAIL

-

Voltage:

-

380V

-

Rated Power:

-

15KW, 20HP

-

Dimension(L*W*H):

-

3200*2200MM

-

Weight (KG):

-

5000 KG

-

Cutting metal thickness:

-

0-100mm

-

Continuous Working Pressure:

-

350-380mpa

-

Cutting accuracy:

-

±0.1mm

-

Power Requirement:

-

(415v/50hz), 380V/50HZ, ( 220v/60hz), 3 phase

-

linear guider:

-

imported from TAIWAN HIWIN

-

Pump type:

-

60000psi direct drive pump

-

Control accuracy:

-

±0.05mm

-

Max pressure:

-

60000psi

-

Certification:

-

CE

-

Control system:

-

5 axis

Heavy duty frame high quality 3d mini cnc waterjet cutting machine price

For more information, Contact:

Email: info(@)chinsailcnc.com, whatsapp/skype: +86 1886 5928 760

|

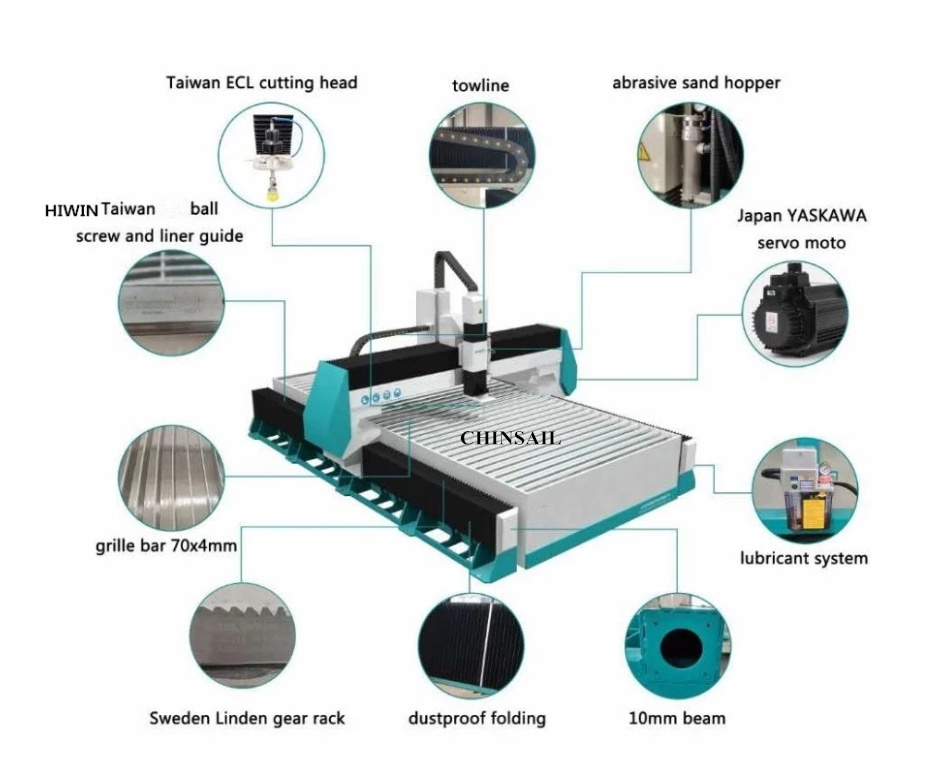

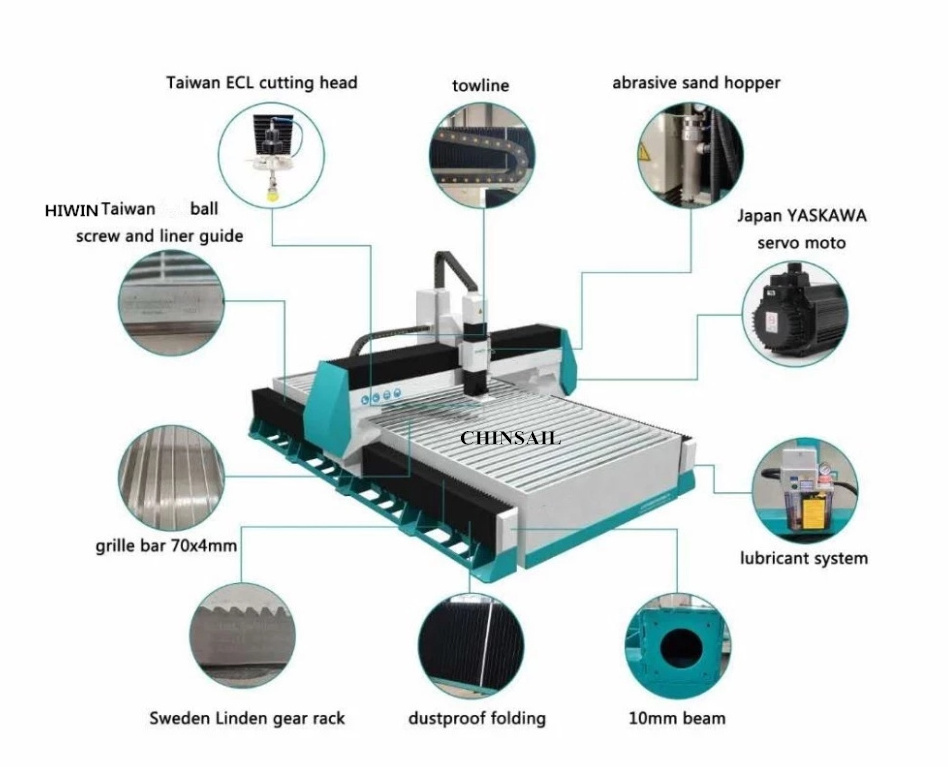

Machine picture & Features

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. The gantry-style balanced design structure is more stable and improves the accuracy of the machine. 2. Ultra-high pressure cutter head , which can be cut with pure water and sand. It has 3-axis and 5-axis cutter heads for vertical and non-vertical cutting with a maximum cutting angle of 60 degrees. 3. The X/Y axis adopts the labyrinth waterproof and sandproof double protection system . 4. The X/Y axis adopts Taiwan's high-quality guide rail and Swedish ball screw. It is durable and the Z-axis fully enclosed structure is guaranteed to be free from water and sand. 5. Heavy-duty machine tools, high-temperature forging, so that the machine will not be deformed during use. 6. China's first generation of self-designed ultra-high pressure servo direct drive pumps are more energy efficient, environmentally friendly and light, and ultra high pressure booster pumps are easier to operate and maintain. 7. The CNC control system uses the WEIHONG professional waterjet cutting CNC system . we also have ITALY imported software which support more than 20 langu ages. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brief Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

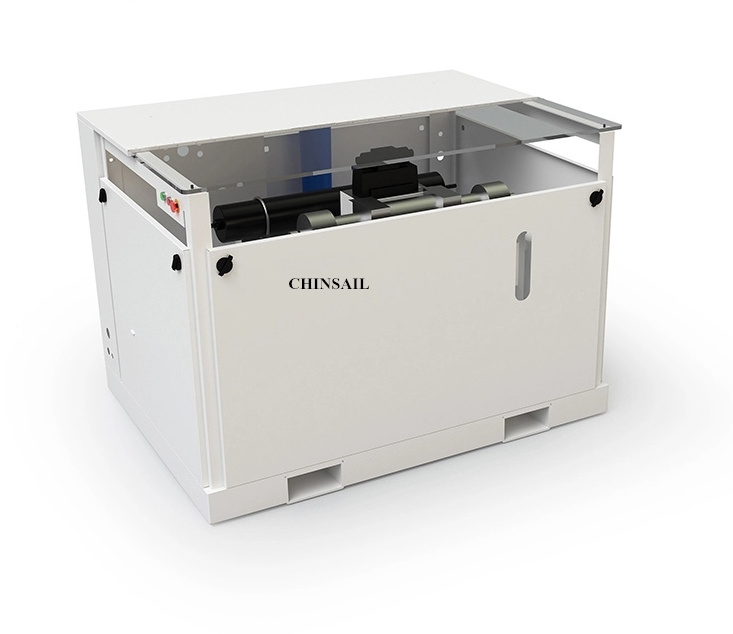

A full set of abrasive waterjet cutting machine includes work table, pump,CNC controller, High pressure system with cooling system, Auto abrasive feeder, Water treatment and Abrasive removal system,etc.

equipment is rigid enough to ensure the stability under l ong-span and high-speed operation. With a multi-point fixing method in the length direction of the frame, there is no any deformation displacement during operation, which ensure the cutting accuracy.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical parameters | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Materials and cutting speed for reference | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Package & Shippping | ||||||

|

||||||

|

FAQ |

||||||

|

1

. What kind of material does your water jet cutting machine can cut?

There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic, rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and cast alloy. 2. What's your CNC water jet cutting machine's max. cutting thickness? Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we suggest cut no more than 150mm for smooth cutting. Now our Z axis distance is 170mm, we can customize for customers. Regular thickness please refer to: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm. 3. How about machine warranty and after-service? The machine is with 2 years warranty. And some countries we have after-service department, we will provide local service, if have no local service, we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days. Also we can provide installation videos. 4. What's your delivery time? Generally speaking is 20-25 days. if have stock, 7-15 days. |

||||||

| Contact information | ||||||

| Email: info(@)chinsailcnc.com, whatsapp/skype: +86 1886 5928 760 | ||||||

| Other related Machines | ||||||

|

||||||

|

Looking forward to your inquiry! Contact us! Email: info(@)chinsailcnc.com, whatsapp/skype: +86 1886 5928 760 |