- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw depends on size

-

Dimension(L*W*H):

-

Various in different models

-

Weight:

-

Various in different models

-

Application:

-

glycol fermentation equipment beer conical beverage fermenter tank

-

Capacity:

-

1000L

-

Inner Polishing Precision:

-

0.4 Micrometer without dead corner

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Controlling System:

-

Temperature, Pressure auto control

-

Insulation material:

-

high density Polyurethane foam; TH=80mm

-

Glycol Jacket:

-

Dimpled plate on cone and side

-

Thickness:

-

3mm for interior shell/2mm for exterior shell

-

test for tank and jacket:

-

Stringent leakage test by water and pressured gas

-

Welding:

-

100% TIG welding with pure argon gas shield

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tiantai / TBE or OEM

-

Voltage:

-

3phase/380(220,400,415,440)v/50 (60)Hz

-

Power:

-

15-70Kw depends on size

-

Dimension(L*W*H):

-

Various in different models

-

Weight:

-

Various in different models

-

Application:

-

glycol fermentation equipment beer conical beverage fermenter tank

-

Capacity:

-

1000L

-

Inner Polishing Precision:

-

0.4 Micrometer without dead corner

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Controlling System:

-

Temperature, Pressure auto control

-

Insulation material:

-

high density Polyurethane foam; TH=80mm

-

Glycol Jacket:

-

Dimpled plate on cone and side

-

Thickness:

-

3mm for interior shell/2mm for exterior shell

-

test for tank and jacket:

-

Stringent leakage test by water and pressured gas

-

Welding:

-

100% TIG welding with pure argon gas shield

-

Certification:

-

CE ISO

1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank

Looking to expand your brewery business? Then check out us.

Our doors are always open so you could take a tour of our manufacturing facilities and meet the people

who make Tiantai an industry leader in craft brewing equipment!

Shandong Tiantai Brewery Configuration includes Malt Milling Unit, Brewhouse Unit, Fermentation Unit,

Beer Filter Unit, Bright Tank Unit, Glycol Cooling Unit, Controlling Unit, CIP unit, Keg Filling and W ashing

Unit, Bottling Machine Unit, etc.

1. Description of 1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank

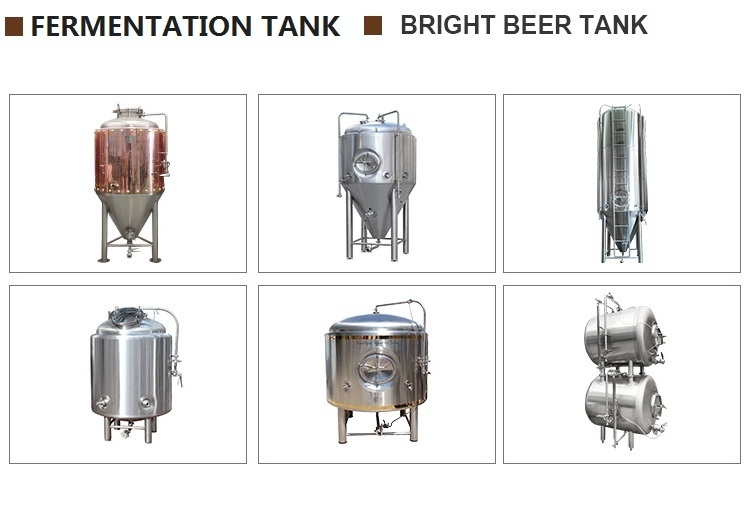

Fermenters are also called CCT’s (Cylindrical Conical Tanks), FV’s (Fermentation Vessel),

primary fermentor or unitanks as they are used both for fermenting and lagering.

Fermenting is the process during which the yeast transforms the wort into beer.

Lagerings takes place after fermenting and is the time given to the beer to stabilize and age

after fermenting.

TBE stainless steel fermenters can be individually temperature controlled through glycol

jackets and are mostly equipped with accessories such as overpressure and under pressure

valve, CIP cleaning jet, sanitary sample valve, manhole,etc. The design of TBE fermenters is

based on our vast beer knowledge and especially the conical fermenter bottom and the fact

that we combine fermentation and maturation in the same vessel is very important.

When calculating your fermenting and lagering capacity and configuration sufficient time for

fermenting and lagering to produce quality beers must be taken into consideration.

2. Configuration of 1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank

|

Fermentation Tank Series |

Volume in US Gallon |

Diameter |

Height |

|

5HL Fermentation Tank |

132US Gallon |

1010mm |

2100mm |

|

10HL Fermentation Tank |

264US Gallon |

1210mm |

2550mm |

|

15HL Fermentation Tank |

396US Gallon |

1560mm |

2620mm |

|

20HL Fermentation Tank |

528US Gallon |

1560mm |

3100mm |

Design pressure 45 psi (3bar); working pressure 15psi (1bar)

4 stainless steel legs with leveling footpads

25% headspace, unless a different volume is requested

Top manway or side manway door

Dual zone in sidewall and cone dimple cooling jacket with glycol inlet and outlet

Polyurethane insulation thickness 80mm for cooling jacket on side and bottom

Fully welded exterior shell

Non welding CIP arm and rotating 360 degree reach spray ball

Solenoid relief valve, pressure relief valve (safe valve) are standard

Pressure gauge

Temperature sensor well

Sanitary sample valve and port

All clamps and gaskets to attach all accessories

Tank complete with piping, fittings, sanitary valves and all parts.

Carbonation port is available for special request (stone not included)

Ladder hooks is available for special request

Dry hop ports and/or hop bag hooks in any fermenter of any size for special request

If you are would like to change, add, remove or modify any part of the tanks, we can

accommodate that. Specific fitting sizes, changes and locations will be set during the design

process after a deposit is taken.

3. Details of 1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank

4 . Production Progress of 1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank

5. Certification of 1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank

6. Advantage of 1000L glycol jacket cooling fermentation equipment beer conical beverage fermenter tank