* The cast wall plate is rejected because of its low pulling force but high deformation, and steel wall plate is applied like Japan machines. The pulling force is enlarged, i.e. the pressing force is enlarged, and it becomes firm and endurable without any deformation.

* The oil route is forcibly lubricated by an oil pump as made in Taiwan to reduce wearing, an oil cooler is added to cool the lubricating oil, and the main chain is lubricated timely to improve the operation efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhenhua Pengyi

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3.8*2.4*2.35m

-

Weight:

-

13 kg

-

Name:

-

Semi-automatic Diecutting & Creasing Machine

-

Usage 1 of die cutter:

-

1-8 mm thickness corrugated paperboard

-

Usage 2 of die cutter:

-

200-2000 GSM Cardboard

-

Max paper size:

-

1300*960mm

-

min paper size:

-

400*400mm

-

max die cutting size:

-

1280*940mm

-

Max die cutting pressure:

-

300 N/cm3

-

Machine speed:

-

4500 sheets/ hours

-

Precision of die cutting machine:

-

+/- 0.5 mm

-

Machine type:

-

Flat form Die Cutting Machine

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

3500 SHEETS/HOUR

-

Max. workable width:

-

1300mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhenhua Pengyi

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3.8*2.4*2.35m

-

Weight:

-

13 kg

-

Name:

-

Semi-automatic Diecutting & Creasing Machine

-

Usage 1 of die cutter:

-

1-8 mm thickness corrugated paperboard

-

Usage 2 of die cutter:

-

200-2000 GSM Cardboard

-

Max paper size:

-

1300*960mm

-

min paper size:

-

400*400mm

-

max die cutting size:

-

1280*940mm

-

Max die cutting pressure:

-

300 N/cm3

-

Machine speed:

-

4500 sheets/ hours

-

Precision of die cutting machine:

-

+/- 0.5 mm

-

Machine type:

-

Flat form Die Cutting Machine

Product Description

Machine Details

* Paper Feeding Unit and Paper Conveying Unit

1)With the unique design of the pre-feeder, side regulation and pedal cylinder control, eliminating manual handing and adjustment cumbersome, time-saving, and improve efficiency.

2)To improve the working efficiency, paper feeding and collecting are realized by Taiwan Chenggang dual-speed reduction motor which provides a long service life and a high torsional force, and it saves time due to its high lowering speed.

3)Paper delivery part monitoring: there is a video interface showing the circumstance of the paper delivery part, which Paper is positioned by a pushing unit and a pulling unit which can be shifted conveniently for different specifications of paper.

2)To improve the working efficiency, paper feeding and collecting are realized by Taiwan Chenggang dual-speed reduction motor which provides a long service life and a high torsional force, and it saves time due to its high lowering speed.

3)Paper delivery part monitoring: there is a video interface showing the circumstance of the paper delivery part, which Paper is positioned by a pushing unit and a pulling unit which can be shifted conveniently for different specifications of paper.

4)A new stability design of hydraulic lifting platform can improve efficiency and safety.

Die-cutting Unit

* The novel transmission mechanism provides high speed die-cutting, and the highly precise swing link platform improves the padding speed (almost without padding), as it is known the pressure can be hardly balanced in most of other common machines.

* The pneumatic plate locking unit can fix the upper frame more firmly and faster. In our die-cutting machine, the front, back, left and right are pneumatically locked simultaneously to realize a high correctness and a high speed. However, common machines are tightened by screws.

* The paper holding rack chain is imported from Germany, which provides a long service life and a stable die-cutting precision.

* The Taiwan intermittent mechanism is the main transmission part of the die-cutting machine, and it improves the die-cutting speed and precision and reduces the device noise, while the speed and precision cannot be realized by any domestic mechanism.

* The torque limiter is equipped with overload protection. The primary and secondary units can be separated at any overload to ensure the machine can be operated safely. The Italia pneumatic brake and clutch with Japan SMC rotary joint comply with the European standard.

* The pneumatic plate locking unit can fix the upper frame more firmly and faster. In our die-cutting machine, the front, back, left and right are pneumatically locked simultaneously to realize a high correctness and a high speed. However, common machines are tightened by screws.

* The paper holding rack chain is imported from Germany, which provides a long service life and a stable die-cutting precision.

* The Taiwan intermittent mechanism is the main transmission part of the die-cutting machine, and it improves the die-cutting speed and precision and reduces the device noise, while the speed and precision cannot be realized by any domestic mechanism.

* The torque limiter is equipped with overload protection. The primary and secondary units can be separated at any overload to ensure the machine can be operated safely. The Italia pneumatic brake and clutch with Japan SMC rotary joint comply with the European standard.

They provide fast clutching, high and stable force, long service life and low noise.

Paper Collecting Unit

* Paper can be collected automatically and orderly.

* The efficiency is improved by an uninterrupted paper collecting grid plate, and when paper is stacked to the specified height,

the paper collecting grid plate will be replaced by another plate for uninterrupted paper collecting.

* By the pneumatic sampling, the die-cut paper can be conveniently inspected at any time.

* The efficiency is improved by an uninterrupted paper collecting grid plate, and when paper is stacked to the specified height,

the paper collecting grid plate will be replaced by another plate for uninterrupted paper collecting.

* By the pneumatic sampling, the die-cut paper can be conveniently inspected at any time.

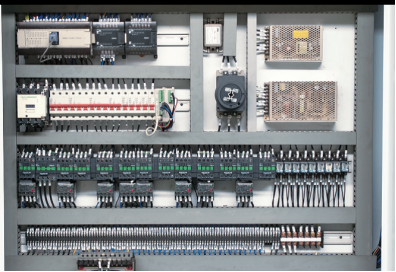

Electrical Control Unit

* The electrical control system is Japan Omron PLC computer automatic control for fully detecting and controlling, and the Japan TOSHIBA frequency converter with Taiwan main motor provides high power for paper feeding, paper conveying, die-cutting, and paper collecting.

* The human-machine interface can display various working conditions, indicate fault positions and give solutions.

* The human-machine interface can display various working conditions, indicate fault positions and give solutions.

Specification

|

Model

|

ZHMY-1300

|

|

Max. paper size (mm)

|

1320×960

|

|

Min. paper size (mm)

|

450×400

|

|

Max. cutting size (mm)

|

1300×940

|

|

Max. pressure(TON)

|

380

|

|

Sheet thickness (mm)

|

1-8

|

|

Max. running speed (s/h)

|

6000

|

|

Total power(KW)

|

14

|

|

Net weight(T)

|

14.5

|

|

Overall dimension (mm)

|

5800×4530×2520

|

|

Air requirements (Buyer provide)

|

0.8Mpa, >0.36m³/min

|

Application

Packing & Delivery

To better ensure the safety of semi automatic die cutting machine, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches