- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HYB

-

Dimension(L*W*H):

-

Variety

-

Weight:

-

30.3 KG

-

Product name:

-

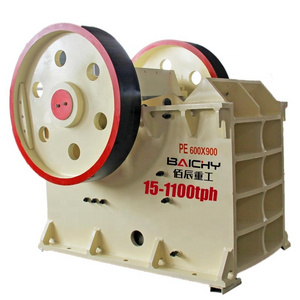

Jaw Crusher Machine

-

Keyword:

-

Jaw Crusher

-

The Machines Classification:

-

Mining Machinery

-

Color:

-

Customer Requirement

-

Processed Materials:

-

Mining Ore Stone

-

Spare Parts Supply:

-

Anytime

-

After sale Service:

-

Online support

-

Feeding Width:

-

1375mm

-

Feeding Depth:

-

760mm

-

Motor Speed:

-

260r/min

Quick Details

-

Application:

-

Ore Mine Stone

-

Capacity(t/h):

-

240-780t/h

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

HYB

-

Dimension(L*W*H):

-

Variety

-

Weight:

-

30.3 KG

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Jaw Crusher

-

The Machines Classification:

-

Mining Machinery

-

Color:

-

Customer Requirement

-

Processed Materials:

-

Mining Ore Stone

-

Spare Parts Supply:

-

Anytime

-

After sale Service:

-

Online support

-

Feeding Width:

-

1375mm

-

Feeding Depth:

-

760mm

-

Motor Speed:

-

260r/min

Original C Series Jaw Crusher

Description

Reliability Design

SC series jaw crusher is developed and applied widely in mines, quarries, road construction, building material, highway, railway,water conservancy and other industrial. The core of Huayue SC Series jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers.In addition to solid casting, SC series jaw crushers’ frame has a cellular, so called honeycomb structure that, like in nature, has proven to be stronger and more durable.

High Production and Reduction

Huayue SC Series jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity.A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions. A steeper nip angle decreases operating costs by reducing wear on jaw dies and speeds up material flow down in the cavity. Jaw crushers are designed modular to save time and installation costs. They can be installed within a few days, minimizing on-site engineering and fabrication.

Features

1.Pinned an d bo lted, non-welded frame construction

2.Outstanding fatigue strength

3.Excellence in casting engineering

4.Premium-quality components

5. Easy to install in place of an existing crusher

6.Option for remote monitoring, automation and settings adjustment

7.Possibility to transport to the site in pieces

Application

Widely used fixed and mobile equipment

1.Stone material

2.Mine(ground surface and downhole)

3.Waste recovery(concrete and bitumen)

4.Industrial(slag and anode)

Working Principle

The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw, and the stuff will be crushed in multiple ways. The angle of Jaw Crusher between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw of jaw crusher moves away from fixed jaw by the pulling force of rod and spring, the products after crushing will be discharged from the outlet of Jaw crusher.

|

MODEL

|

|

SC80

|

SC100

|

SC96

|

SC106

|

SC116

|

SC3054

|

SC110

|

SC125

|

|

|

Feed Opening Width(mm)

|

|

800

|

1000

|

930

|

1060

|

1150

|

1375

|

1100

|

1250

|

|

|

Feed Opening Depth(mm)

|

|

510

|

760

|

580

|

700

|

800

|

760

|

850

|

950

|

|

|

Motor Power(kW)

|

|

75

|

110

|

90

|

110

|

132

|

160

|

160

|

160

|

|

|

Rotating Speed(rpm)

|

|

350

|

260

|

330

|

280

|

260

|

260

|

230

|

220

|

|

|

Discharge Openging

(mm)

|

Close Side Setting

(mm)

|

t/h

|

t/h

|

t/h

|

t/h

|

t/h

|

t/h

|

t/h

|

t/h

|

|

|

0-30

|

20

|

|

|

|

|

|

|

|

|

|

|

0-35

|

25

|

|

|

|

|

|

|

|

|

|

|

0-45

|

30

|

|

|

|

|

|

|

|

|

|

|

0-60

|

40

|

65-85

|

|

|

|

|

|

|

|

|

|

0-75

|

50

|

80-95

|

|

|

|

|

|

|

|

|

|

0-90

|

60

|

95-125

|

|

120-155

|

|

|

|

|

|

|

|

0-105

|

70

|

115-150

|

150-210

|

140-180

|

155-200

|

170-220

|

240-310

|

190-250

|

|

|

|

0-120

|

80

|

130-170

|

175-225

|

160-210

|

175-230

|

190-250

|

270-350

|

210-275

|

|

|

|

0-135

|

90

|

150-195

|

190-245

|

180-235

|

200-260

|

215-280

|

295-385

|

235-305

|

|

|

|

0-150

|

100

|

165-215

|

215-280

|

200-260

|

220-290

|

240-310

|

325-425

|

255-330

|

290-380

|

|

|

0-185

|

125

|

210-275

|

265-345

|

250-325

|

280-365

|

295-385

|

390-510

|

310-405

|

350-455

|

|

|

0-225

|

150

|

250-325

|

315-410

|

300-390

|

335-435

|

350-455

|

460-600

|

370-480

|

410-535

|

|

|

0-260

|

175

|

290-380

|

370-480

|

350-455

|

390-510

|

405-525

|

530-690

|

425-550

|

470-610

|

|

|

0-300

|

200

|

|

420-545

|

|

445-580

|

460-600

|

600-780

|

480-625

|

530-690

|

|

|

0-340

|

225

|

|

|

|

|

|

|

|

590-770

|

|

|

0-375

|

250

|

|

|

|

|

|

|

|

650-845

|

|

|

0-410

|

275

|

|

|

|

|

|

|

|

|

|

|

0-450

|

300

|

|

|

|

|

|

|

|

|

|

|

MODEL

|

|

SC140

|

SC145

|

SC160

|

SC200

|

|

|

Feed Opening Width(mm)

|

|

800

|

1000

|

930

|

1060

|

|

|

Feed Opening Depth(mm)

|

|

510

|

760

|

580

|

700

|

|

|

Motor Power(kW)

|

|

75

|

110

|

90

|

110

|

|

|

Rotating Speed(rpm)

|

|

350

|

260

|

330

|

280

|

|

|

Discharge Opening(mm)

|

Close Side Setting(mm)

|

t/h

|

t/h

|

t/h

|

t/h

|

|

|

0-30

|

20

|

|

|

|

|

|

|

0-35

|

25

|

|

|

|

|

|

|

0-45

|

30

|

|

|

|

|

|

|

0-60

|

40

|

|

|

|

|

|

|

0-75

|

50

|

|

|

|

|

|

|

0-90

|

60

|

|

|

|

|

|

|

0-105

|

70

|

|

|

|

|

|

|

0-120

|

80

|

|

|

|

|

|

|

0-135

|

90

|

|

|

|

|

|

|

0-150

|

100

|

|

|

|

|

|

|

0-185

|

125

|

385-500

|

400-520

|

|

|

|

|

0-225

|

150

|

455-590

|

470-610

|

520-675

|

|

|

|

0-260

|

175

|

520-675

|

540-700

|

595-775

|

760-990

|

|

|

0-300

|

200

|

590-765

|

610-795

|

675-880

|

855-1110

|

|

|

0-340

|

225

|

655-850

|

680-885

|

750-975

|

945-1230

|

|

|

0-375

|

250

|

725-945

|

750-975

|

825-1070

|

1040-1350

|

|

|

0-410

|

275

|

|

825-1070

|

900-1170

|

1130-1470

|

|

|

0-450

|

300

|

|

|

980-1275

|

1225-1590

|

|

|

|

SC80

|

SC100

|

SC96

|

SC106

|

SC116

|

SC3054

|

||||||

|

Crusher Weight(kg)

|

7670

|

20060

|

9759

|

14350

|

18600

|

25900

|

||||||

|

Crusher Total Weight(kg)

|

9520

|

23300

|

11870

|

17050

|

21500

|

30300

|

||||||

|

|

SC110

|

SC125

|

SC140

|

SC145

|

SC160

|

SC200

|

||||||

|

Crusher Weight(kg)

|

25800

|

37970

|

47120

|

54540

|

71330

|

121510

|

||||||

|

Crusher Total Weight(kg)

|

29500

|

43910

|

54010

|

63190

|

83300

|

137160

|

||||||

|

Total Weight: Includes crusher, hydraulic regulating device, flywheel cover, motor seat, hopper, automatic lubrication system and motor.

|

|

|

|

|

|

|

||||||