- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

60

-

Weight (KG):

-

2500

-

Name:

-

scrap metal shredder machine

-

Keyword:

-

plastic crusher machine

-

Final product:

-

1-10 cm

-

Capacity:

-

2-60t

-

Production Capacity (kg/h):

-

500 - 17000 kg/h

-

Application:

-

Recycle Waste Metal

-

Function:

-

Scrap Metal Crushing

-

Color:

-

Client's Requirements

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Key words:

-

High Efficiency Metal Recovery

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2022

-

Brand Name:

-

Xrido

-

Power (kW):

-

60

-

Weight (KG):

-

2500

-

Name:

-

scrap metal shredder machine

-

Keyword:

-

plastic crusher machine

-

Final product:

-

1-10 cm

-

Capacity:

-

2-60t

-

Production Capacity (kg/h):

-

500 - 17000 kg/h

-

Application:

-

Recycle Waste Metal

-

Function:

-

Scrap Metal Crushing

-

Color:

-

Client's Requirements

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Key words:

-

High Efficiency Metal Recovery

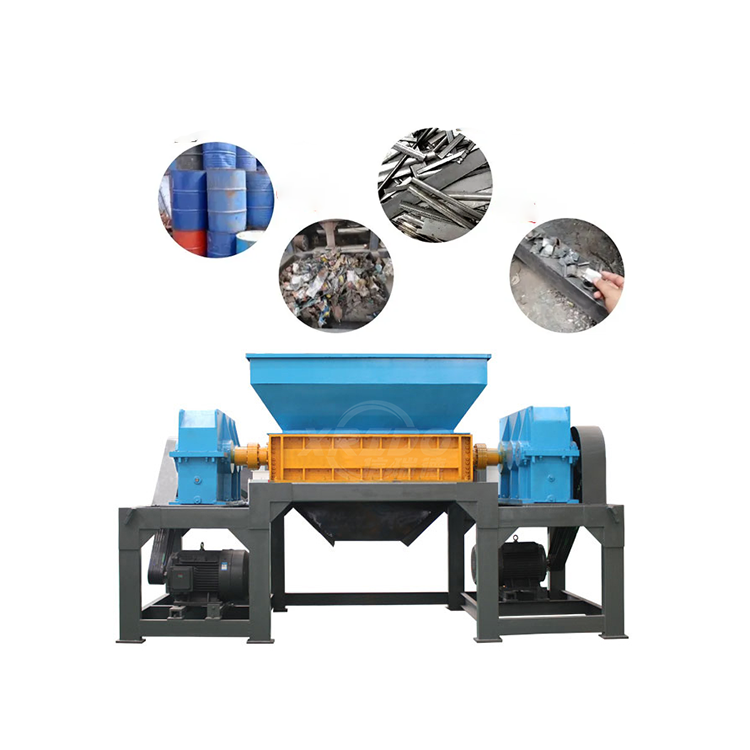

Products Description

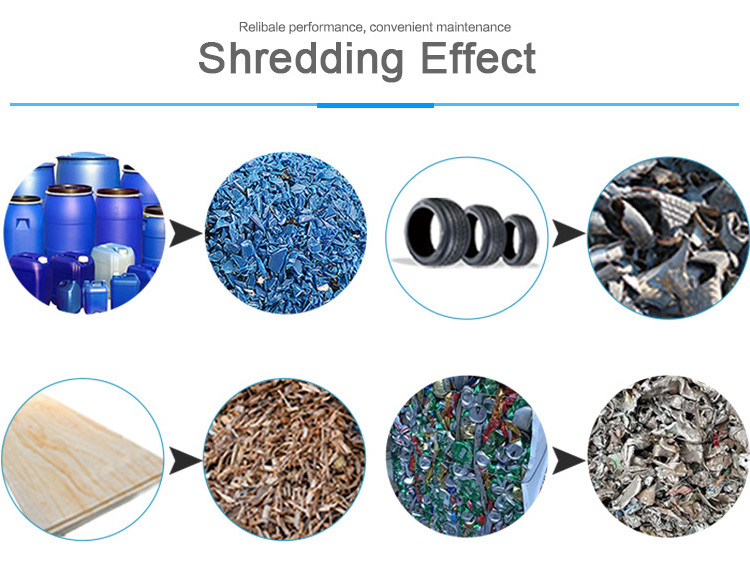

The double shaft shredder

have been designed for a wide array of applications and industries, suitable for shredding solid material such as E-waste, metal,wood, plastic,scrap tires, packaging barrel, pallets,etc. Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction. It is widely used in industry waste recycling, electronic recycling, pallet recycling,municipal solid waste recycling,plastic recycling,tire recycling,paper making industry and etc.

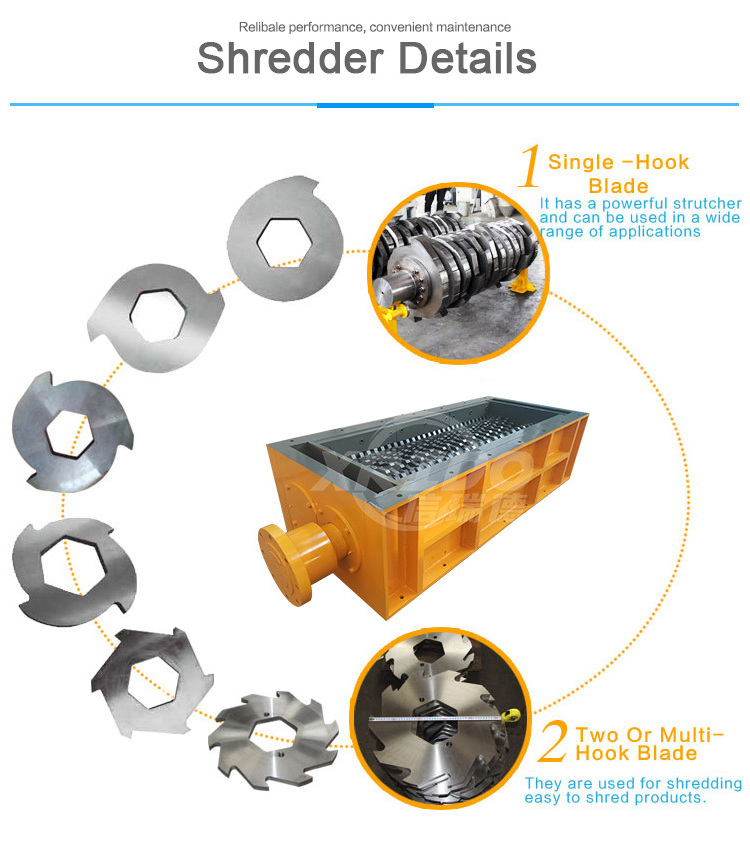

Details Images

Biaxial shredders use two-axis independent drive,so that the production of materials to produce the corresponding pressure, to achieve automatic feeding function,a unique knife shaft structure and four-corner rotary tool,low speed high torque in the production process, There will be no winding shaft,or stuck phenomenon of the device,thereby increasing the production efficiency,the device is suitable for all kinds of toughness, high viscosity material crushing.

High quality waste shredder/plastic crusher machine is used to shred the woods, building templates, old furniture, timbers,plastics, rubbers, fibers, paper, batteries, large-scale hollow materials (plastic and other large container), and a variety of mixed wastes (especially wastes containing metal or sediment, such as: roll film, woven bag, TV set, refrigerator shells, car and medium car tires and hollow barrels, fishing nets, cardboard, circuit boards, etc. )

Product Paramenters

|

model

|

size(LxWxH)

|

blade diameter

|

blade quantity

|

weight

|

|

RDS-80

|

2800x1300x1850

|

275

|

72

|

3600

|

|

RDS-100

|

3000x1300x1850

|

275

|

96

|

4000

|

|

RDS-120

|

3300x1900x2200

|

315

|

120

|

6500

|

|

RDS-140

|

3600x2000x2200

|

315

|

144

|

7500

|

|

RDS-160

|

4180x2100x2400

|

350

|

180

|

9000

|

|

RDS-180

|

5400x2700x3500

|

500

|

240

|

20000

|

Why Choose Us

1. It has the characteristics of low speed, high torque and low noise. It is controlled by PLC. It has the functions of starting,stopping, reversing and overloading automatic reversing.

2. The motor + reducer drives the cutter shaft to achieve the shearing effect of low speed and high torque.

3. Bearing six-fold seal, effective waterproof and dust-proof, prolong the service life of bearings.

4. After tool wear, the repair technology of tool coating and welding is adopted to realize the repeated use of the tool, which greatly reduces the maintenance cost of the tool.

5. Separate box design, can easily and quickly remove the entire axle (axle, blade, bearing, sealing system).

6. Tools are arranged according to helix to achieve high efficiency cutting.

7. Both the inner hole and the spindle face of the cutter are designed in hexagonal form to realize the uniformity of the force exerted on the cutter.

8. According to different materials and product shapes to be torn up, different types of cutters can be selected.

Product packaging

Hot Searches