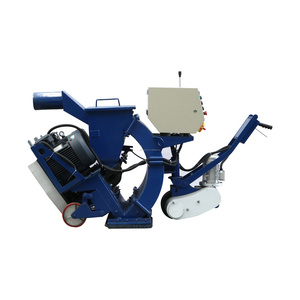

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2*11kw

-

Dimension(L*W*H):

-

2000*850*1500mm

-

Name:

-

Shot Blast Cleaning Machine

-

After-sales Service Provided:

-

Engineers

-

Application:

-

Steel Plate Surface Cleaning

-

Function:

-

Metal Rust Surface Cleaning

-

Type:

-

Shot Blasting Machine Equipment

-

Dust collector:

-

Bag

-

Working Width:

-

550mm

-

Concrete Surface Cleaning Efficiency:

-

80m/h

-

Steel Shot Diameter:

-

1.5-1.8mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

geb

-

Weight (KG):

-

800 KG

-

Power:

-

2*11kw

-

Dimension(L*W*H):

-

2000*850*1500mm

-

Name:

-

Shot Blast Cleaning Machine

-

After-sales Service Provided:

-

Engineers

-

Application:

-

Steel Plate Surface Cleaning

-

Function:

-

Metal Rust Surface Cleaning

-

Type:

-

Shot Blasting Machine Equipment

-

Dust collector:

-

Bag

-

Working Width:

-

550mm

-

Concrete Surface Cleaning Efficiency:

-

80m/h

-

Steel Shot Diameter:

-

1.5-1.8mm

Product Description

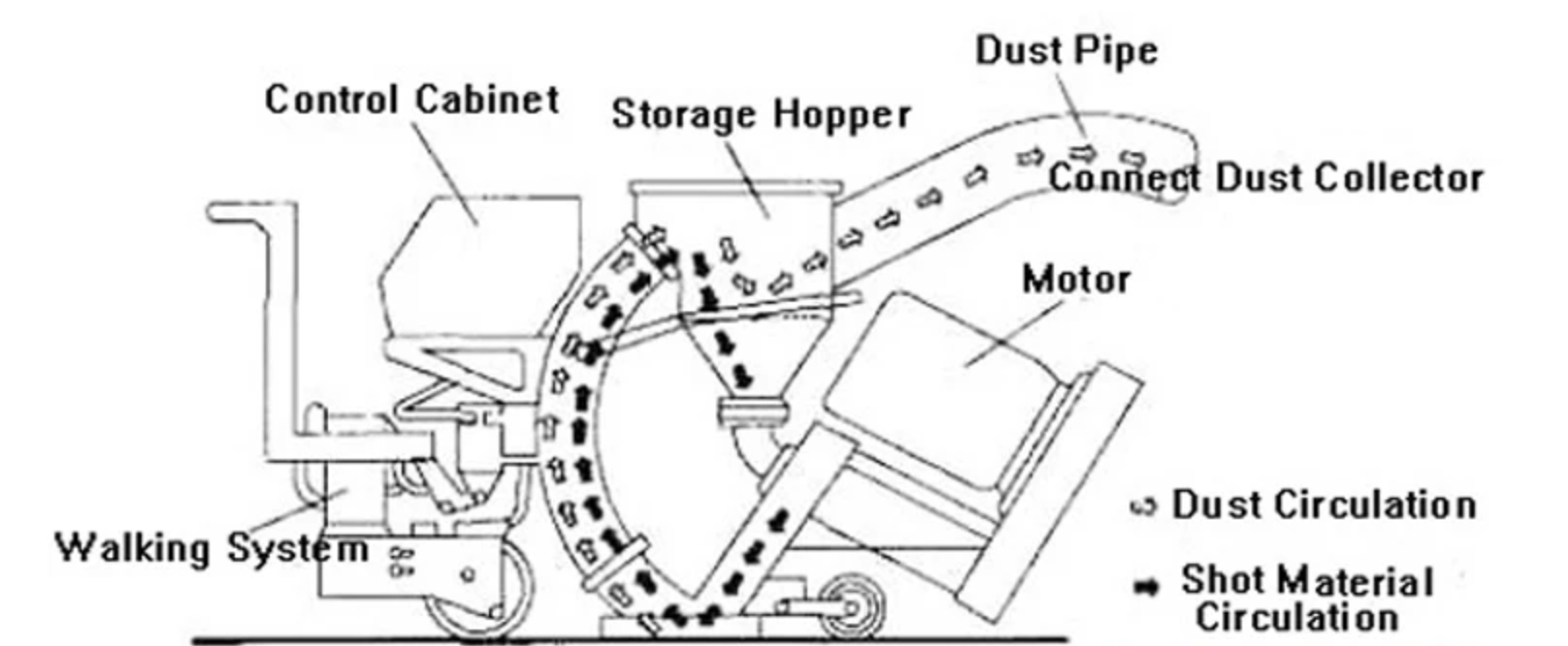

Road Surface shot blasting machine can successively clear away the concrete surface laitance and impurities, and cando polishing processing to the concrete surface, make its surface achieve uniform roughness. Greatly improve the adhesive strength of the waterproof layer and concrete base, so that better combine the waterproof layer and deck.

Specification

1.

It is used to improve the asphalt pavement roughness and friction coefficient, so as to improve the adhesion of the road surface and ensure the safety of driving. At the same time, asphalt fixtures (such as fuel, oil, etc.) also have nowhere to run, thus improving the skid resistance of the pavement

2. Anti-corrosion coating of the steel bridge deck

The application of shot blasting in the anticorrosive coating of steel bridges is undeniable. Most Bridges under construction and completed construction use a shot blasting machine for surface cleaning and roughness treatment prior to antiseptic primers or other sprays

3. Tunnel maintenance

Due to the consideration of waterproof, fire resistance, and oil resistance of materials, cement concrete is generally used for the pavement inside the tunnel. But it also puts forward a higher requirement for the anti-skid performance of the long tunnel road surface. Shot blasting technology is a treatment method with simple construction, small equipment input, remarkable effect, and environmental protection.

4. Preventive maintenance of airport runways

The use of road shot blasting machines makes the removal of tread marks and marking on concrete and asphalt runway easy and simple. The treatment range of the road blasting machine is to remove the tread (rubber), remove the marking, restore and increase the surface roughness of the airport runway and increase the friction coefficient of the runway. Moreover, in the process of treatment, the road blasting is more orderly.

5. Municipal roads and paved roads

All kinds of road paving in the city can use the shot blasting machine for cleaning treatment, and remove the road signs and markers, for busy intersections, the road surface can be brushed, improving the pavement roughness and friction coefficient. Reduce problems in pavement construction. Therefore, the auxiliary role of road blasting machines in urban.

|

Model

|

GEB -270S

|

GEB-600D

|

|

Maximum cleaning size

|

270 mm

|

550 mm

|

|

Concrete surface effect rate

|

150m2/ h

|

320m2/ h

|

|

Blasting device

|

1 set

|

2 sets

|

|

Device power

|

11 kw

|

11 kw

|

|

Separator air volume

|

6~8 m³/s

|

6~8 m³/s

|

|

Running style

|

Electric control

|

Electric control

|

|

Driving Motor power

|

0.55 kw

|

0.75 kw

|

|

Running speed(frequency control)

|

5-25 m/min

|

5-25 m/min

|

|

|

|

|

|

Shot first loading capacity

|

80 kg

|

80 kg

|

|

Suggest shot diameter

|

1.0-1.5 mm

|

1.0-1.5 mm

|

|

Dust collect way

|

Blow back

|

Blow back

|

|

Power of dust collector

|

5.5 kw

|

6.2 kw

|

|

Connection pipe diameter

|

150 mm

|

150 mm

|

|

Total power of machine

|

17 kw

|

29 kw

|

|

Overall dimension of blaster

|

L1950 x W380x H1130

|

L1950x W850x H1400

|

|

Weight of blaster

|

420 kg

|

670 kg

|

|

Dimension of dust collector

|

L1420 x W860 x H1650

|

L1700x W1050x H1750

|

|

Weight of dust collector

|

530 kg

|

615 kg

|

|

Weight of spare parts

|

160 kg

|

160 kg

|

Details Images

Application

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certifications

FAQ

Q1. What can we do if there are problems with the products?

A: Our engineers will analyze the problem for you and find the best solution. If problems happened within the guaranteed time, we can replace the components for you free of charge. We have dealers in some countries, for some technical problems which you can not solve by yourself.

Q2. What is the delivery time for your products?

A: Once we promise the delivery time, we will try our best to fulfill it. Special procedures such as emergency inventory will be used to maintain your uninterrupted supply of the products.

Q3. Is there any guarantee for your products?

A: Most of our products have one year guarantee(for the main parts).

Q4. How can you control your product quality?

A: Quality is always considered the most important part of our manufacturing process. All of our products come under a strict quality control system from raw material inspection, component inspecting,semi-finished product inspecting, and performance test of finished products, to random inspection before delivery.

Hot Searches