- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2380

-

Size:

-

3510*1200*1300, Customized Size

-

Power:

-

4---11KW

-

Weight (KG):

-

2380 kg

-

Product name:

-

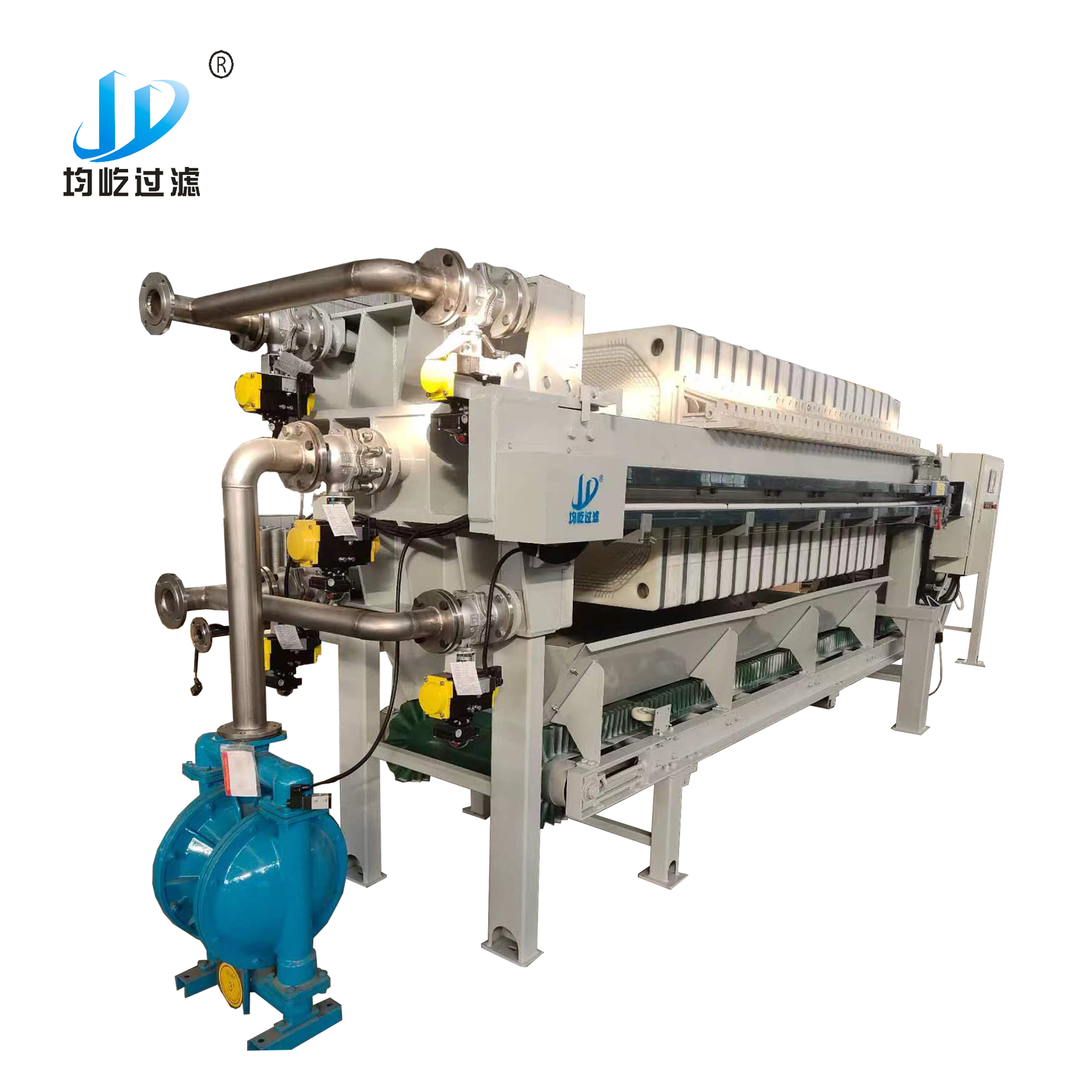

Hydraulic membrane Filter press

-

Function:

-

solid-liquid separation

-

Type:

-

Conventional filter press

-

Feature:

-

Low moisture content of filter cake

-

Filter Media:

-

Filter Cloth

-

Filtration area:

-

1---1000㎡

-

Flow rate:

-

1-300 M3/h

-

Compression method:

-

Hydraulic compression

-

Key words:

-

Filter press

Quick Details

-

Core Components:

-

Filter plate, Frame, Electric control system, Pressure gauge, Hydraulic pump

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Junyi

-

Weight:

-

2380

-

Size:

-

3510*1200*1300, Customized Size

-

Power:

-

4---11KW

-

Weight (KG):

-

2380 kg

-

Product name:

-

Hydraulic membrane Filter press

-

Function:

-

solid-liquid separation

-

Type:

-

Conventional filter press

-

Feature:

-

Low moisture content of filter cake

-

Filter Media:

-

Filter Cloth

-

Filtration area:

-

1---1000㎡

-

Flow rate:

-

1-300 M3/h

-

Compression method:

-

Hydraulic compression

-

Key words:

-

Filter press

Product Description

The

membrane filter press

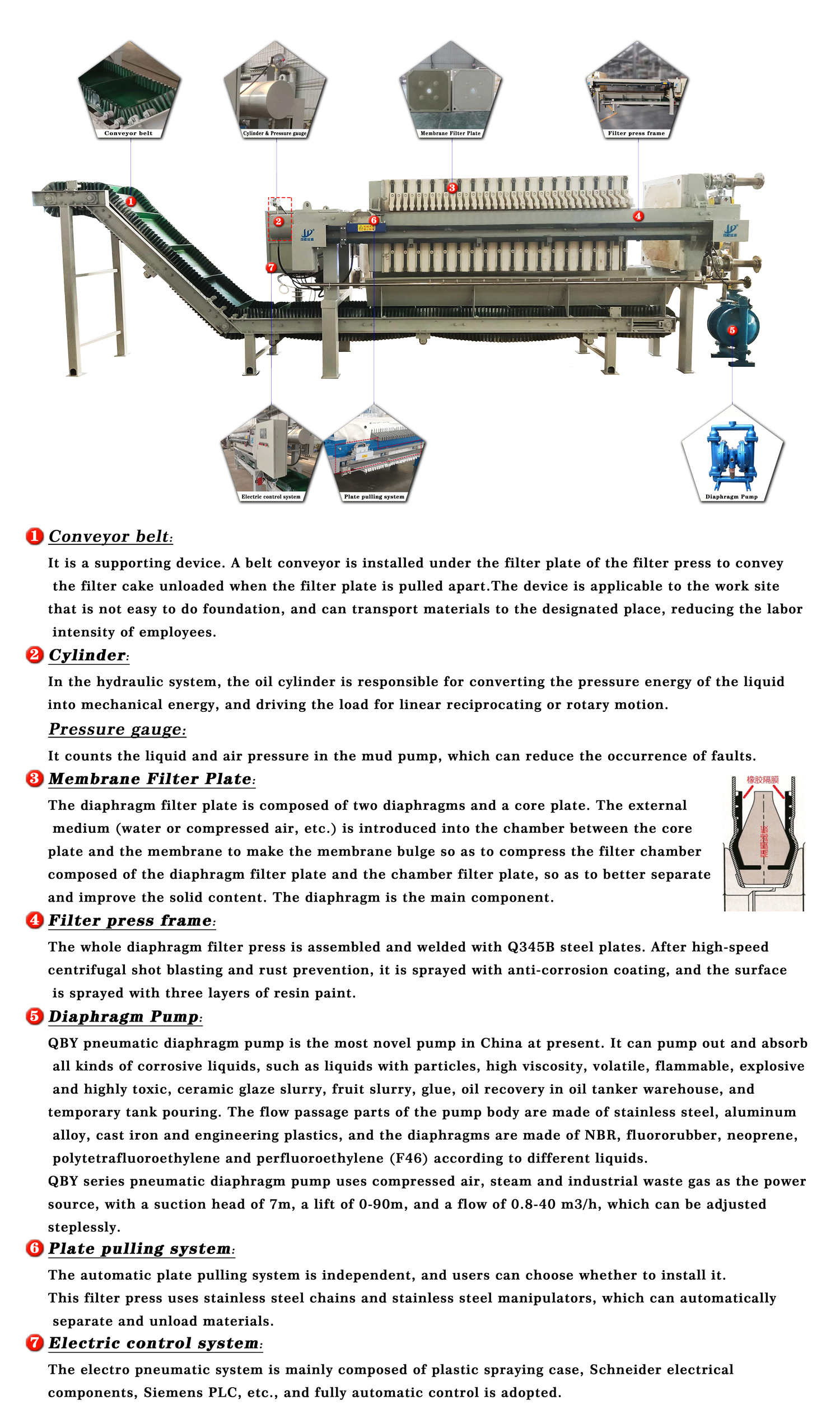

is composed of a filter chamber arranged by diaphragm plates and box filter plates. Under the pressure of the feed pump, the slurry is input into the filter chamber. The solid and liquid in the slurry are separated through the filter medium (filter cloth). When the solid in the slurry forms a cake, air is introduced to the diaphragm to fully press the solid in the filter chamber. Reduce water content. Especially for the filtration of viscous materials and users with high requirements for moisture content, this machine has its unique characteristics. The filter plate is molded from reinforced polypropylene. The diaphragm and polypropylene plate are inlaid together, which is firm, reliable, not easy to fall off, and has a long service life. It is equipped with a variety of safety devices to ensure the safety of the operator and the normal operation of the filter press.

Product details

Contact Us

Specification

|

Filtration Pressure:0.6-1.0Mpa

Filter Cake thickness:30mm

Motor power:4.0Kw

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

Filter area

(㎡)

|

Filter plate size(mm)

|

Volume of filter chamber(L)

|

Number of filter plates

(pcs)

|

Weight

(Kg)

|

|

30

|

870*870

|

412

|

23

|

|

|

40

|

|

520

|

29

|

2380

|

|

50

|

|

653

|

37

|

2750

|

|

60

|

|

798

|

45

|

3165

|

|

80

|

|

1083

|

61

|

3703

|

|

50

|

100*100

|

680

|

27

|

4226

|

|

60

|

|

819

|

33

|

4386

|

|

80

|

|

1108

|

45

|

5510

|

|

100

|

|

1386

|

57

|

6328

|

|

120

|

|

1675

|

69

|

7150

|

Feature

Advantages of membrane filter press

1. Low pressure filtration and high pressure pressing can greatly shorten the entire filtration cycle.

2. With TPE elastomer, the maximum filtering pressure can reach 2.5MPA, which greatly reduces the water content, saves drying costs and improves the yield.

3. Save the consumption of operating power. In the later stage of filtration, the flow is small and the pressure is high.

4. The diaphragm pressing function can complete this process in a very short time, saving power consumption.

5. The mud biscuit degree is improved and the mud cake content is reduced. The diaphragm press presses the filter cake after the static filtration for a second time, so that the structure of the filter cake is rearranged and the density is increased, thus replacing some of the water and improving the dryness.

6. It has strong corrosion resistance and is basically applicable to all solid-liquid separation operations.

7. PLC and human-machine interface control can be configured.

8. Diaphragm filter plate has the characteristics of fatigue resistance, aging resistance and good sealing performance.

Applicable industries

It is widely used in the yellow wine filtration, rice wine filtration, stone wastewater, ceramic clay, kaolin and the construction material industry.

Related Products

Hot Searches