Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XinQuan

-

Voltage:

-

380V 50Hz or Customized

-

Dimension(L*W*H):

-

25000x5000x6000mm

-

Power (kW):

-

80

-

Weight:

-

1000 KG

-

Product name:

-

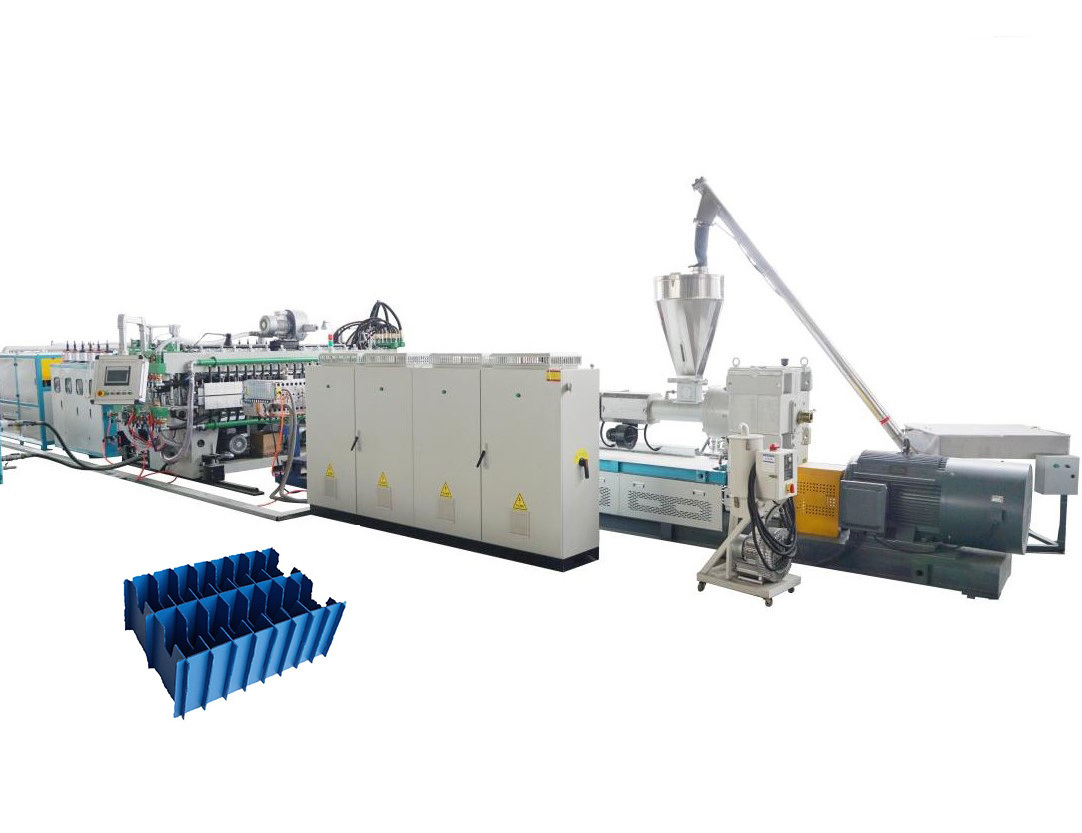

Board Making Machine PP PC Hollowness Grid Board Production Line

-

Keywords:

-

Board Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic Grade:

-

Automatic

-

After Warranty Service:

-

Field maintenance and repair service

-

Output (kg/h):

-

150 - 250 kg/h

-

Certification:

-

CE Certificate

-

Power of main motor:

-

75KW-110KW

-

Product width:

-

1200-2600mm

-

Product thickness:

-

2-12mm

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

80

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XinQuan

-

Voltage:

-

380V 50Hz or Customized

-

Dimension(L*W*H):

-

25000x5000x6000mm

-

Power (kW):

-

80

-

Weight:

-

1000 KG

-

Product name:

-

Board Making Machine PP PC Hollowness Grid Board Production Line

-

Keywords:

-

Board Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic Grade:

-

Automatic

-

After Warranty Service:

-

Field maintenance and repair service

-

Output (kg/h):

-

150 - 250 kg/h

-

Certification:

-

CE Certificate

-

Power of main motor:

-

75KW-110KW

-

Product width:

-

1200-2600mm

-

Product thickness:

-

2-12mm

Product description

|

Extruder model

|

SJ-100/35

|

SJ-120/35 –SJ150/35

|

|

Motor power

|

75KW

|

110-132KW

|

|

Product width

|

1300-1600mm

|

1600-2600mm

|

|

Product thickness

|

2-10mm

|

2-10mm

|

Single screw extruder

Most specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding. auto spiral screw feeding system. screw and barrel material is 38CrMoAla. complete line is fully automatic.

Mould of extruder

The mould uses high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

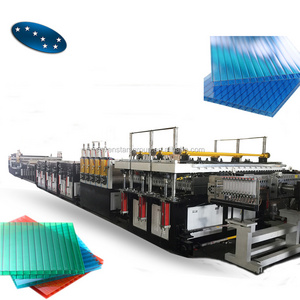

Cooling form mould plate

Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point

type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree

of plate surface.

type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree

of plate surface.

Haul-off device

Configure two haul-off for whole line. first one is high power/ reduction ratio, multi-roller type, well low-speed operation, be able to draw the plate up from the calibrating table evenly and synchronous. The second is designed to remove stress, equip edge-cutting device to ensure the valid width and smooth cutting edges.

Depress oven

The oven removes the stress of hollow sheet, the heating oven is made by 304 stainless steel, equipped with separately temperature control system for each zone to ensure the heating to be uniform, 4 meter lengths for heating oven operation is necessary.

Wind cooling machine

Cooling improve the surface finish of plastic products, reduce the surface marks and internal stress of plastic products, keep the products from shrinking and deformation, accelerate product shaping, and improve the production efficiency of plastic molding machines.

Automatic cutter

After corona treatment, the cutting machine accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade to realize high-quality cutting. forward and backward is controlled by pneumatic.

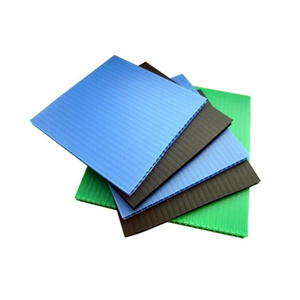

Hollow profile board

The pp hollow profile board has the features, light weight, high tenacity, damp proof, environmental performance and secondary

processing. Instead of cartons paper with high recycling rate.

processing. Instead of cartons paper with high recycling rate.

Product Application

The PP hollow grid board can be processed into turnover case, packaging case, clapboard, lining board, backing board and pallet,etc, due to its advantages of light weight, high tenacity, damp proof, environmental performance and secondary processing. It is widely used in such fields as the electron, household electrical appliances, packaging, machinery, postal, food, pesticide and advertisement decoration, etc.

Products Recommended

Production Flow Chart

Company Introduction

Certifications

Exhibition

Packaing&Transportration

Hot Searches