Cast iron, aluminum, copper, steel, brass, zinc, bronze,titanium and magnesium, they are also suitable for treating a variety of other machining scraps.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Briquette metal scrap briquetting press machine

-

Materials:

-

Waste metal

-

Voltage:

-

380V or customized

-

Weight:

-

4.8-13.5t

-

Usage:

-

Automatic Control Operation

-

Dimension:

-

0.81m*0.81m*3.5m(HY-300)

-

Feature:

-

Energy Saving

-

Power:

-

22-49Kw

-

Finished product diameter:

-

100-160mm

-

Color:

-

Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HengYuan

-

Weight (KG):

-

3000

-

Product name:

-

Briquette metal scrap briquetting press machine

-

Materials:

-

Waste metal

-

Voltage:

-

380V or customized

-

Weight:

-

4.8-13.5t

-

Usage:

-

Automatic Control Operation

-

Dimension:

-

0.81m*0.81m*3.5m(HY-300)

-

Feature:

-

Energy Saving

-

Power:

-

22-49Kw

-

Finished product diameter:

-

100-160mm

-

Color:

-

Customized

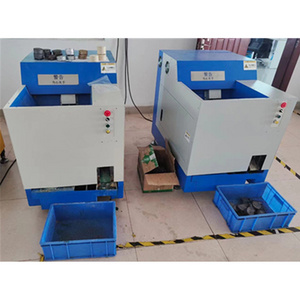

Introduction of briquette metal scrap briquetting press machine

The iron powder after this machine is suppressed is bottled directly, burn and make the sponge iron, compared with the situation that the tradition is bottled by hand have output high, it is fast to reduce, save the energy, lengthen characteristics such as the service life of the fire-resistant pot, etc.

This machine adopts and imports PLC to automatically control completely, the scientific and technological content is high, reduces workers' labour intensity greatly, thus improved output and quality of the products.

This machine is four column type presses, adopt the hydraulic transmission scheme optimized, have strong motive force, accurate localization and perfect movement association. This machine fault rate is low, the caloric value is small, the productivity is high, it is durable to economize on electricity.

|

Model

|

Block diameter (mm)

|

Block density (T/M3)

|

Block weight (kg)

|

Power (kw)

|

|

HY-200

|

Φ80-100

|

4.0-5.2

|

2-3

|

11

|

|

HY-300

|

Φ100-120

|

4.2-5.5

|

2-4

|

15-22

|

|

HY-400

|

Φ110-140

|

4.2-5.5

|

3-5

|

22-30

|

|

HY-500

|

Φ120-150

|

4.5-5.5

|

5-8

|

30

|

Working principle of briquette metal scrap briquetting press machine

1.The electrical part adopts PLC control, strong anti-interference, high degree of automation, simple operation.

2.The hydraulic station adopts integral valve block and large through valve to eliminate oil leakage, reduce the oil temperature of the system and improve the stability of the system.

3.The whole steel castings are adopted in the part of the frame, which can prevent the cracking of the welding parts of the steel plates and improve the reliability and service life of the equipment.

4.The oil cylinder adopts tandem type oil cylinder, which improves the movement speed and production efficiency.

5.According to the working condition of the user, it has spiral automatic feeder and chain type automatic feeder, which reduces the labor intensity of the workers.

Press Materials of briquette metal scrap briquetting press machine

Main Features of briquette metal scrap briquetting press machine

It is featured of durability, stable running, computer-aided control, high automation, low fault rate, and easy maintenance.

Main Features of briquette metal scrap briquetting press machine

It is designed with independent driving structure and electrial appliance system as well as centered buttons control, characterized of easy operation and sound driving performances.

Pre-Sales Service

1.Professional introduction and suggestion on raw material, machine selection, workshop condition, feasibility analysis, etc.

2.Reasonable recommendation (according to the raw material, capacity and the size of block)

3.24 hours on-line service.

4.Welcome to visit our factory anytime, if you need, we can make invitation card for you.

After-Sales Service

1.Engineer available to help with installation and test the machine overseas if needed.

2.Warranty one year after delivery.

3.Training support to the operator until they are satisfied.

4.Recall clients regularly, get feedback in time, keep well communication with each other.