- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Name/hot search /keywords:

-

Polythene polyethylene Bag manufacturing Making Machine Price

-

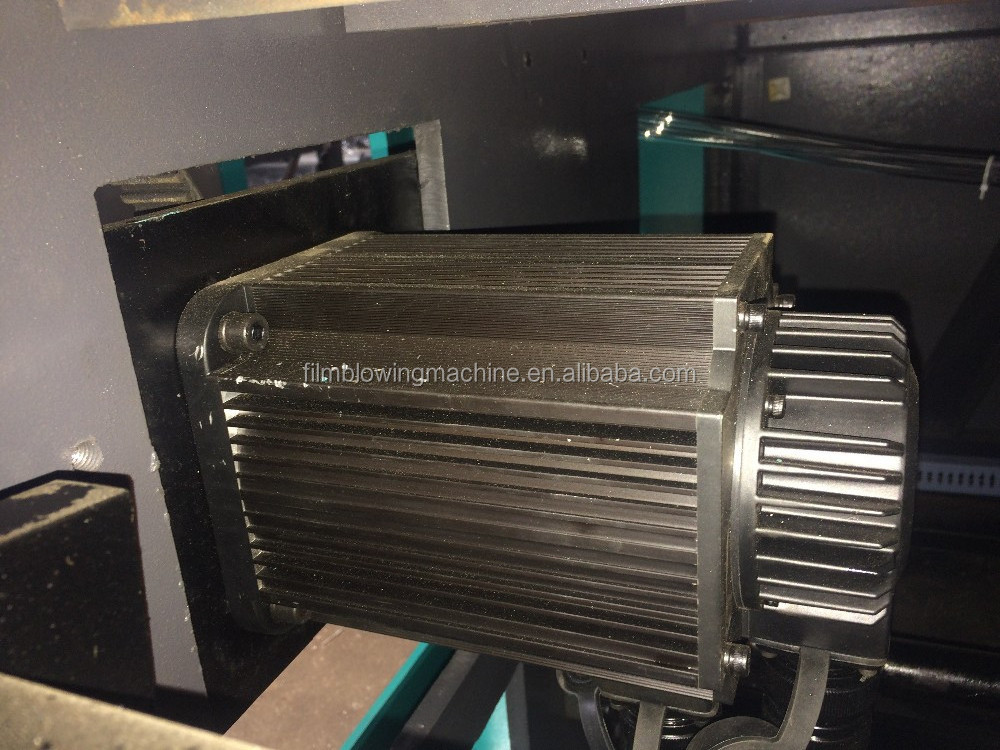

Feeding motor:

-

Servo motor, high quality

-

bag making speed:

-

120pcs/min*2steams

-

Inverter:

-

DELTA brand from Taiwan

-

Electric parts:

-

CHINT ,best supplier in China

-

Sealing knife:

-

high quality copper materials, longer life

-

Cutting knife materials:

-

Alloy steel from Japan,very hard ,no need to sharp

-

Photocell:

-

SICK Germany

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

T-shirt Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Name/hot search /keywords:

-

Polythene polyethylene Bag manufacturing Making Machine Price

-

Feeding motor:

-

Servo motor, high quality

-

bag making speed:

-

120pcs/min*2steams

-

Inverter:

-

DELTA brand from Taiwan

-

Electric parts:

-

CHINT ,best supplier in China

-

Sealing knife:

-

high quality copper materials, longer life

-

Cutting knife materials:

-

Alloy steel from Japan,very hard ,no need to sharp

-

Photocell:

-

SICK Germany

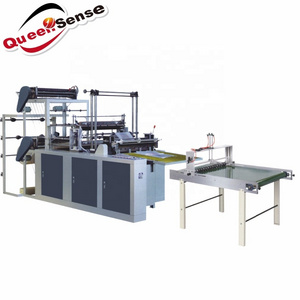

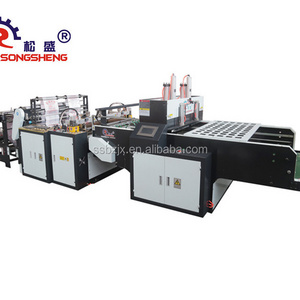

Plastic Shopping Bag Making Machine

Final Product and Usage

1. Machine Introduction

It is used for producing vest bags and flat-opening bags with printing. The main motor adopts frequency

conversion motor to save more electricity and regulate speed more freely. The color code tracker with

good performance makes the sealing and cutting length more accurately and the error smaller. It adopts

advanced computer to adjust length more freely and accurately.

2. Machine Advantages

1, We use stronger steel plate for machine body, which make machine more stable

2, Computer controlling, more accurate and precise.

3, Yasawa servo motor and driver controlling, which make the cutting more accurate.

4, Electric parst is CHINT, best supplier in China.

5, Easy to operate, one woker is enough.

3. Machine Parameters

|

Model |

RG-DL600 |

RG-DL700 |

RG -DL800 |

RG-DL900 |

RG-DL1000 |

|

width of sealing &cutting(mm) |

500 |

600 |

700 |

800 |

900 |

|

length of sealing & cutting(mm) |

700 |

1200 |

1200 |

1500 |

1600 |

|

speed of bag-making (pc/min) |

240-300 |

240-300 |

150-260 |

150-200 |

150-200 |

|

Power of motor(kw) |

1.1 |

1.5 |

1.5 |

2 |

2 |

|

Weight(kg) |

700 |

850 |

850 |

1000 |

1000 |

|

Outline dimension (m) |

3.2×1.2×1.7 |

3.5 x 1.3 x 1.7 |

3.5 x 1.3 x 1.8 |

3.7 x 1.6 x 2 |

3.8 x 1.8 x 2.1 |

4. Machine Details

We also have other products, If you interest ,Please Click it

1,Q: Your factory is trading company or factory?

A: We are factory. We have more 2100 square meter workshop and 23 workers containing the

2 installment engineer and 1 electric engineer.We are Factory, so we have cost advantage than others

2, Q: How do your company control the machine quality?

A: First we control the raw materials quality.

Second, we control the quality of machine when we are processing.

Third, Our installment engineer will test machine.

3, Q: How about payment term, payment safety and delivery time?

A: We accept 30% deposit, balance before shipment. And Irrevocable L/C at sight.

Delivery time is 20 to 30 days. It is according to order quantity.

4,Q: What is your company after sale service?

A: Our installment engineers are available. Normally it will take about 7 to 10 days for all.

Our guarantee is one year. If there is any spare parts is broken, we can send them freely to you.

We also have other products, If you interest ,Please Click it