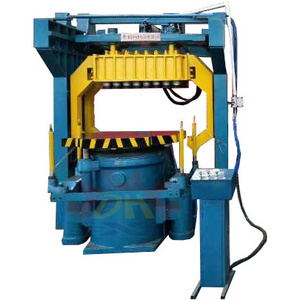

1. Most parts of the molding machine are ductile iron castings, and the quality of castings is very important

2. Our Huaxin Company has its own foundry and casting testing laboratory to ensure the quality of molding machines from the source.

3. After the casting comes out, it will go through a series of machining processes. The company has over 30 sets of machining equipment to ensure timely delivery.

4. After the casting is processed, polished, assembled and welded to the fuselage.

5. Connect the air source, debug and test run to ensure that the equipment delivered from the factory is qualified equipment.