- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TOPFRP

-

Model Number:

-

TOP2200

-

Surface Treatment:

-

All thread

-

Product Name:

-

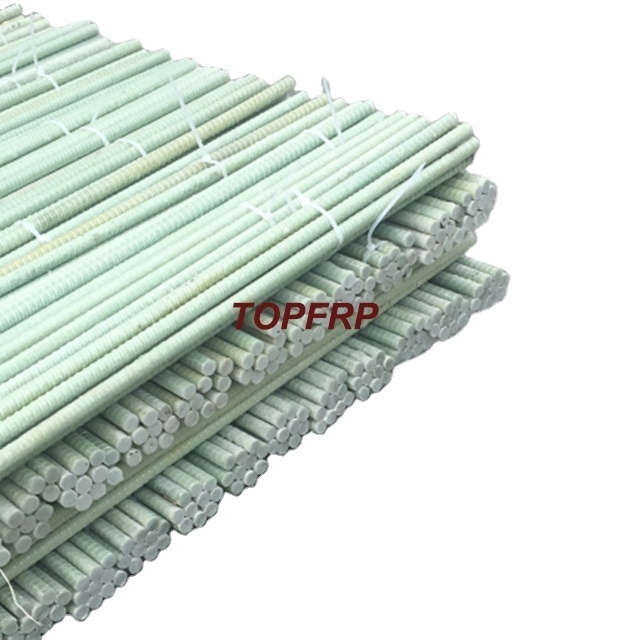

Low Price Glass Fiber Reinforced Polymer Rebar

-

Material:

-

Fiberglass Reinforced Polymer

-

Diameter:

-

3-40mm

-

Density:

-

2.0-2.2g/cm3

-

Tensile Strength:

-

>550MPa

-

E-modulus:

-

30-41GPa

-

Resistance to alkali:

-

>75%

-

Feature:

-

High Strength,Corrosion Resistant

-

OEM:

-

Accepted

-

Other Name:

-

GFRP rebar

Quick Details

-

Application:

-

Construction,building,industry,and agriculture

-

Technique:

-

Pultrusion

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TOPFRP

-

Model Number:

-

TOP2200

-

Surface Treatment:

-

All thread

-

Product Name:

-

Low Price Glass Fiber Reinforced Polymer Rebar

-

Material:

-

Fiberglass Reinforced Polymer

-

Diameter:

-

3-40mm

-

Density:

-

2.0-2.2g/cm3

-

Tensile Strength:

-

>550MPa

-

E-modulus:

-

30-41GPa

-

Resistance to alkali:

-

>75%

-

Feature:

-

High Strength,Corrosion Resistant

-

OEM:

-

Accepted

-

Other Name:

-

GFRP rebar

Low Price Glass Fiber Reinforced Polymer Rebar

----------------------------Main Features of Polymer Rebar-------------------------------

Corrosion resistance;Tensile strength is twice of steel;Non-conductive&non-thermal;

Elastic modulus is stable; Good wave transmission performance, no shielding;Prefabricated standard bends and other shapes,n o sparks during cutting, especially suitable for high gas area.

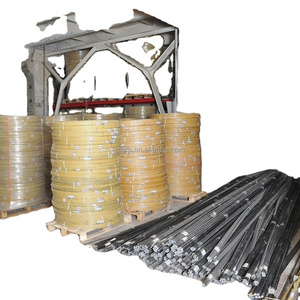

--------------------------Pultrusion Process of

Polymer

Rebar---------------------------

Customer feedback

-----------------------------Application of

Polymer

Rebar---------------------------------

Fiberglass polymer rebar has become a material for replacing steel bars in reinforced concrete structures, and have good corrosion resistance and electromagnetic neutrality.

1. widely used in highways, bridges, airports, terminals, stations, water conservancy projects, underground engineering and other fields

2. Suitable for corrosive environments such as sewage treatment plants, chemical plants, electrolysis tanks, manhole covers, and coastal defense projects.

3. Suitable for military engineering, confidential engineering, special engineering, etc.

--------------------------- Technical Index o f Polymer Rebar------------------------------

|

Diameter

(mm)

|

Cross Section

(mm2)

|

Density

(g/cm3)

|

Weight

(g/m)

|

Ultimate Tensile Strength

(MPa)

|

Elastic

Modulus

(GPa)

|

|

3

|

7

|

2.2

|

18

|

1900

|

>40

|

|

4

|

12

|

2.2

|

32

|

1500

|

>40

|

|

6

|

28

|

2.2

|

51

|

1280

|

>40

|

|

8

|

50

|

2.2

|

98

|

1080

|

>40

|

|

10

|

73

|

2.2

|

150

|

980

|

>40

|

|

12

|

103

|

2.1

|

210

|

870

|

>40

|

|

14

|

134

|

2.1

|

275

|

764

|

>40

|

|

16

|

180

|

2.1

|

388

|

752

|

>40

|

|

18

|

248

|

2.1

|

485

|

744

|

>40

|

|

20

|

278

|

2.1

|

570

|

716

|

>40

|

|

22

|

355

|

2.1

|

700

|

695

|

>40

|

|

25

|

478

|

2.1

|

970

|

675

|

>40

|

|

28

|

590

|

2.1

|

1195

|

702

|

>40

|

|

30

|

671

|

2.1

|

1350

|

637

|

>40

|

|

32

|

740

|

2.1

|

1520

|

626

|

>40

|

|

34

|

857

|

2.1

|

1800

|

595

|

>40

|

|

36

|

961

|

2.1

|

2044

|

575

|

>40

|

|

40

|

1190

|

2.1

|

2380

|

509

|

>40

|