- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

KYT

-

Voltage:

-

380V or as customer requiry

-

Dimension(L*W*H):

-

5000*600*900mm

-

Weight:

-

3500 kg

-

Feeding width:

-

according to client's request

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Octagon Tube Forming Machine

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC(detla) System

-

Application:

-

Construction Panel

-

Thickness:

-

0.3-0.8mm Thickness

-

Cutting type:

-

Hydraulic Cutting

-

Advantage:

-

High Efficent

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15-20 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

KYT

-

Voltage:

-

380V or as customer requiry

-

Dimension(L*W*H):

-

5000*600*900mm

-

Weight:

-

3500 kg

-

Feeding width:

-

according to client's request

-

Marketing Type:

-

New Product 2022

-

Product name:

-

Octagon Tube Forming Machine

-

Raw material:

-

PPGI

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC(detla) System

-

Application:

-

Construction Panel

-

Thickness:

-

0.3-0.8mm Thickness

-

Cutting type:

-

Hydraulic Cutting

-

Advantage:

-

High Efficent

Product Overview

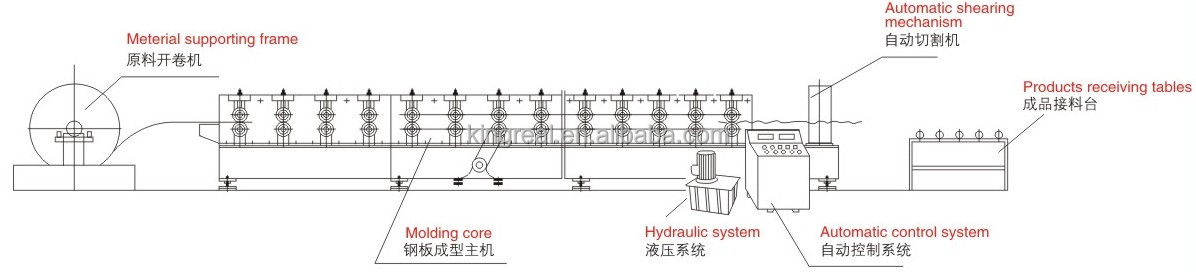

Octagon Tube Pipe Roller Shutter Door Roll Forming Machine

This product is used for the roller shutter door, the product is first by the punching machine hole, then into the tile machine through the wheel hub molding, the final production of Octagon Yube, this machine is made by the punching machine, uncoiler, forming parts and saw cutting and plc control system

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Specification

|

|

|

||

|

Power

|

Motor Power

|

5.5kw

|

|

|

||

|

2

|

Hydraulic power

|

3kw

|

|

|

||

|

3

|

Voltage

|

380V or as customer requiry

|

|

|

||

|

Machine

|

Rolling thinckness

|

0.3-0.8mm

|

|

|

||

|

5

|

Roller Stage

|

20 stations

|

|

|

||

|

6

|

Side Panel

|

25mm

|

|

|

||

|

7

|

Machine Weight

|

3500kg

|

|

|

||

|

8

|

Feeding width

|

235mm or according to client's request

|

|

|

||

|

|

Production Capacity

|

15-20 m/min

|

|

|

||

|

|

Shaft diameter

|

40mm-50mm

|

|

|

||

|

|

Roller Material

|

Gcr15 steel Chrome Plated

|

|

|

||

|

Cutter

|

Hardness

|

Heat treatment(HRC58-62°)

|

|

|

||

|

|

Cutting tolerance

|

± 1mm

|

|

|

||

|

|

Material

|

Cr12

|

|

|

||

|

|

Operation

|

Saw cutting

|

|

|

||

|

Control system

|

PLC brand

|

Delta made in Taiwan or according to client's request

|

|

|

||

|

|

Screen

|

Touchable screen

|

|

|

||

|

|

Language

|

Chinese and English or add customer need language

|

|

|

||

|

Decoiler

|

Operation

|

Manual/Electrical/Hydraulic

|

|

|

||

|

|

Weight capacity

|

3 Tons manual one

|

|

|

||

|

|

Price

|

Manual one free as a gift

|

|

|

||

|

Receiving table

|

Operation

|

Manual

|

|

|

||

|

|

Length

|

3 m

|

|

|

||

|

|

Price

|

Free as gift

|

|

|

||

Working Flow

Component Of Machine

Electrical decoiler

This one mainly used to support steel coils, and automatic uncoil and straighten the coil into the feeding table.Its coil width up to client's drawing.

Punching machine

The punching machine is designed to punch holes before the coil enters the tile making machine, depending on the client's template or drawing.Its

Punching hole mold is

Cr12 mov

PLC control system

Our factory generally provides customers with Delta brand PLC control systems, which can also be equipped according to customer requirements.

Receiving table

This one we will give to the clients as free gift.This one for placing the finished slats in case the final slats get damaged and reducing the manual taking which gets more convenient.

None stop saw cutting

This part is the wheel molding products for cutting, our cutting part is made of Cr12mov, it is hardened by high temperature, making it more durable and strong, with a longer service life

Hydraulic pump

46# hydraulic oil (according to local temperature). Along with this pump,there will be a motor with fan would be much better and it can get rid of the heat.

RELATED PRODUCT

Perforated shutter door roll forming machine

The perforated roll forming machine is made by connecting plastic parts, and the screw fixation at the connection position adopts a concealed design to increase the appearance of the door body. The connection between the profile and plastic parts adopts processes such as punching, pressing, and drilling, making the door structure firm and without welding points. Cross connection design: The cross pipe is made by process punching and equipped with PA wear-resistant sleeve, which is tightly combined with the circular pipe to not only ensure the structure of the door truss is firm, but also ensure smooth operation.

Australia Type Roller Shutter Door Roll Forming Machine

This Australia type roll forming machine both solemn and elegant, beautiful and novel, and has a flat appearance, uniform ripples, high strength, and the advantages of production automation are high degree, low cost, and durability.We also have the seaming machine to make them together

Metal Shutter Door Bottom Slat Roll Forming Machine

The bottom beam, an important component of the roller shutter door, is pressed by a machine customized by the customer. The shape of the bottom beam can also be customized according to the customer's needs

Hydraulic cutting U guide rail shutter door roll forming machine

The U guide rail consists of Manual Decoiler -- Feeding and Guiding Table -- Main Roll Forming Machine -- Plc Control System -- Hydraulic Punching and Cutting Device -- Product Receiving Table The U guide profile produced by the sliding door slide way making machine is used together with shutter door panel and the bottom strips of the shutter door .These three profiles cannot be separated , they should be used together

pu foam shutter door roll forming machine

Equipment features: shutter door machine adopts advanced automatic control software, shutter door machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

COMPANY SHOW

PACKING & DELIVERY

Our package and shipping

1. We will wipe anti rust oil for the whole machine .

2. Plc controller will be covered by foam film

3. Spare parts are some small parts are packed in a wodden case.

4. All componenets are fixed well by steel wire with container.

1. We will wipe anti rust oil for the whole machine .

2. Plc controller will be covered by foam film

3. Spare parts are some small parts are packed in a wodden case.

4. All componenets are fixed well by steel wire with container.

FAQ

Q1: Are you a manufacturer?

A1:Yes, we are professional manufacturer of the roll forming machine

Q2. What are the main key points for selecting right machines?

A2: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A8: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

When you arrive our station, we will arrange to pick up you there!

A1:Yes, we are professional manufacturer of the roll forming machine

Q2. What are the main key points for selecting right machines?

A2: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point. Good quality is for long-term business cooperation.

Q3. Can you provide OEM service for roll forming machine?

A3: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q4. How about the after-sale service?

A4: We provide 5 years free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q5:I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

A5: If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 -100 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

Q6: I receive a lot of quotations, they are big range, How could i choose?

A6: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

Q7: I have not whatsapp and skype, how could I contact with you?

A7: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

Q8. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A8: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

When you arrive our station, we will arrange to pick up you there!

Contact Us

Hot Searches