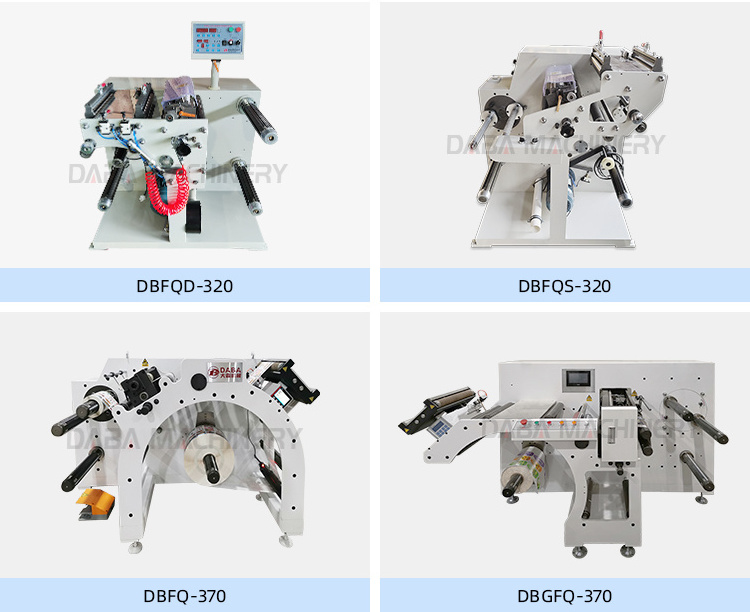

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1300mm*960mm*1500mm

-

Weight:

-

500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Label Slitting Machine

-

Speed:

-

200m/min

-

Material:

-

Adhesive Paer, PP, BOPP, Aluminum

-

Precision:

-

±0.10mm

-

Max. unwind diameter:

-

700mm

-

Max. rewind diameter:

-

200mm

-

Cutter:

-

Circular / Razor

-

Max. Slitting Width:

-

330mm

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

300 m/min

-

Max. workable width:

-

500mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1300mm*960mm*1500mm

-

Weight:

-

500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Label Slitting Machine

-

Speed:

-

200m/min

-

Material:

-

Adhesive Paer, PP, BOPP, Aluminum

-

Precision:

-

±0.10mm

-

Max. unwind diameter:

-

700mm

-

Max. rewind diameter:

-

200mm

-

Cutter:

-

Circular / Razor

-

Max. Slitting Width:

-

330mm

Machine Description

1.Paper cutting machine to the entire volume or the entire printing material for the cut of a fixed length, such as supermarket labels, must use fixed-length slitting control

2.Slitting length can be set continuously, if it’s error of the actual slitting length, it’s easy to calibrate by the way of set the parameters.

3.The slitting control of paper slitting machine is in 2 modes:

static slitting and dynamic slitting.

- Static slitting: Accurately stop when the set length arrives, and then static cutting, and restart operation after cutting.

- Dynamic slitting: without stopping but send slitting signal when the set length arrives, and then dynamic cutting directly on the process of material movement

* Self-adhesive paper,Self-adhesive thermal paper,thermal paper ATM etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

- Unwinding unit adopt photoelectric web guide system, with high precision. Control mode in two steps: manual and automatic

- Rewinding way: center coiling

- The tension control of unwinding unit and rewinding unit is adopt automatic tension control system; the control modes are tension feedback control and taper control.

- The machine keep round cutter and flat cutter two tools, with reliable quality, easy to adjust.

- The slitter has fixed length automatic stop and the length meter automatically functions.

- The Slitter has trimming device, the edge material discharged by the fan.

- The machine is applicable for the slitting operation for the varies of thin coils of narrow band (insulating materials, mica tape, film, etc.)

|

Model

|

DBGFQ-370

|

DBGFQ-470

|

|

|

Max.Slitting Speed

|

350m/min

|

|

|

|

Max. Web Width

|

370mm

|

470mm

|

|

|

Max. Slitting Width

|

350mm

|

450mm

|

|

|

Min. Slitting Width

|

15mm

|

15mm

|

|

|

Slitting Knife (Up/Down)

|

each 6pcs / set

|

Each 6pcs (standard)

|

|

|

Max. Unwinding Diameter

|

800mm

|

800mm

|

|

|

Max.Up Rewinding Diameter

|

800mm

|

800mm

|

|

|

Max. Down Rewinding Diameter

|

800mm

|

800mm

|

|

|

Slitting Cutter

|

Circular knife

|

|

|

|

Slitting Precision

|

±0.10mm

|

±0.10mm

|

|

|

Weight

|

1300KGS

|

1500KGS

|

|

|

Dimension (L * W * H )

|

2200*1350*1350mm

|

2200*1450*1350mm

|

|

Detail Images

1.Unwinding 4.Touch screen 7.Up turret rewinding

2.Web-guide 5.Slitting 8.Down rewinding

3.Control panel 6.Trimming

1 Unwinding Unit

a.Touch screen auto tension,easy to operate

b.Scales on the shaft,dia clear to see

c.Photoelectric material lack stop,stop in time

2 Web Guide

a.Ultrasonic type System with high precision

b.Designed for high speed,rewinding smoothly

c.With Splice table,rolls easy to connect

3 Control Panel

a.Knob switch button,smooth interaction

b.Number/meter counting,stop accurately

c.Double side control design,easy to reach

4 Touch Screen

a.Machine running status,clear at a glance

b.Detailed parameters set easily

6 Trimming

a.Vacuum type,stable trimming

b.1.1kw fan,high-power for high speed

5 Slitting Unit

a.Razor knife for film/foil,diversified needs

b.Auto knives as optional,safe and convenient

c.With scales,slitting width easy to set

7 UP-Rewinding Unit

a.Adopts flange design,airshaft easy to change

b.Adopts(1-6)"airshaft,for different sizes

c.Turret design,small-dia roll simply rewind

8 Down-Rewinding Unit

a.Flange design with cylinder,stable flexible

b.Max.dia 700mm,rewinding easily handled

Samples show

In Factory Photo

Packing & Delivery

Our Service

OUR SERVICE

1.Purchase Service

DABA COMPANY have a specialize and efficiency working team.

If you are new onthe printing and packing area Some samples of your products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

2.Shipping Service

DABA COMPANY have a spcialized and independent department which just for shipping the buyer's goods.

The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

3.Installation Services

Installation Services are available with all DABA Company machines.

DABA Comapnywill dispatch technician to The Buyer's factory to installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

4.Clients Training Services

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.

DABA Company technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

5.After Sales Service

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with machines.

Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

Hot Searches