- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.13-0.19(w/m.k)(800-1000Degree)

-

Thickness:

-

6/10/15/20/25/30/40/50 mm

-

Width:

-

600/1000mm

-

Length:

-

900/1000/1200mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

-3(24hours)

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Ceramic Fibre Board

-

Brand Name:

-

LUYANGWOOL

-

Product Name:

-

Ceramic Fibre Board

-

Density:

-

260/320kg/m3

-

Useage:

-

Furance Insulation

-

Raw material:

-

Ceramic Fiber Bulk

-

Package:

-

Carton+Pallet

-

Feature:

-

Excellent Tensile Strength

-

Product Keywords:

-

LUYANG RCF Board

-

Working Temp:

-

1050/1100/1200/1350

-

Manufacturer:

-

LUYANG

-

Sample:

-

Offered for free

Quick Details

-

Chemical Composition:

-

AL2O3+SIO2

-

Ultimate Strength (≥ MPa):

-

0.5MPa

-

Fiber Diameter:

-

3-5um

-

Thermal Conductivity:

-

0.13-0.19(w/m.k)(800-1000Degree)

-

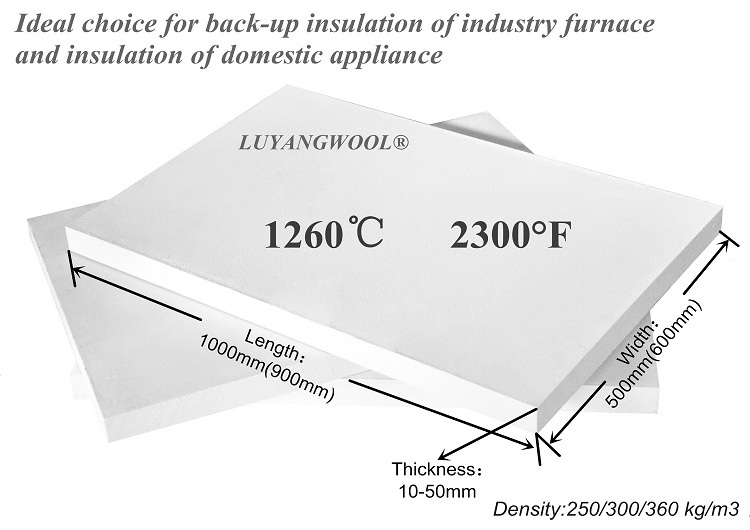

Thickness:

-

6/10/15/20/25/30/40/50 mm

-

Width:

-

600/1000mm

-

Length:

-

900/1000/1200mm

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

-3(24hours)

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Ceramic Fibre Board

-

Brand Name:

-

LUYANGWOOL

-

Product Name:

-

Ceramic Fibre Board

-

Density:

-

260/320kg/m3

-

Useage:

-

Furance Insulation

-

Raw material:

-

Ceramic Fiber Bulk

-

Package:

-

Carton+Pallet

-

Feature:

-

Excellent Tensile Strength

-

Product Keywords:

-

LUYANG RCF Board

-

Working Temp:

-

1050/1100/1200/1350

-

Manufacturer:

-

LUYANG

-

Sample:

-

Offered for free

Products Description

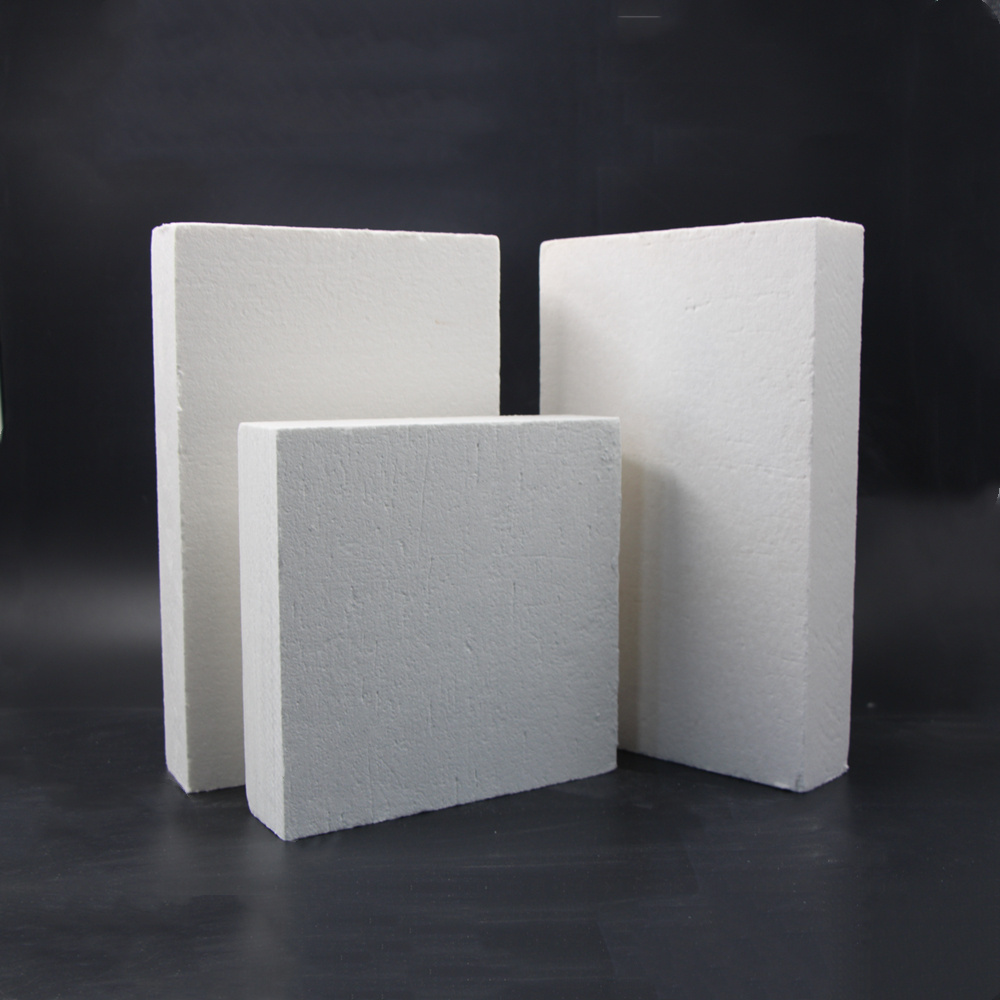

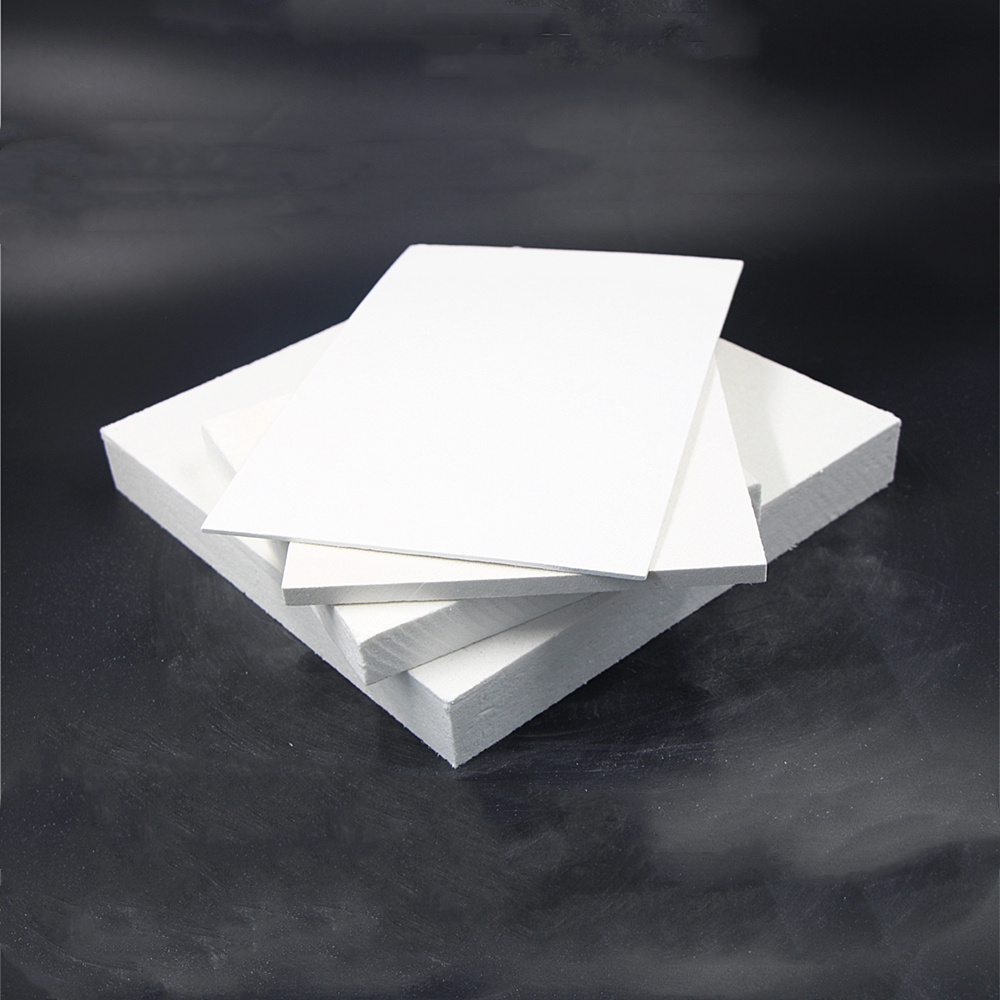

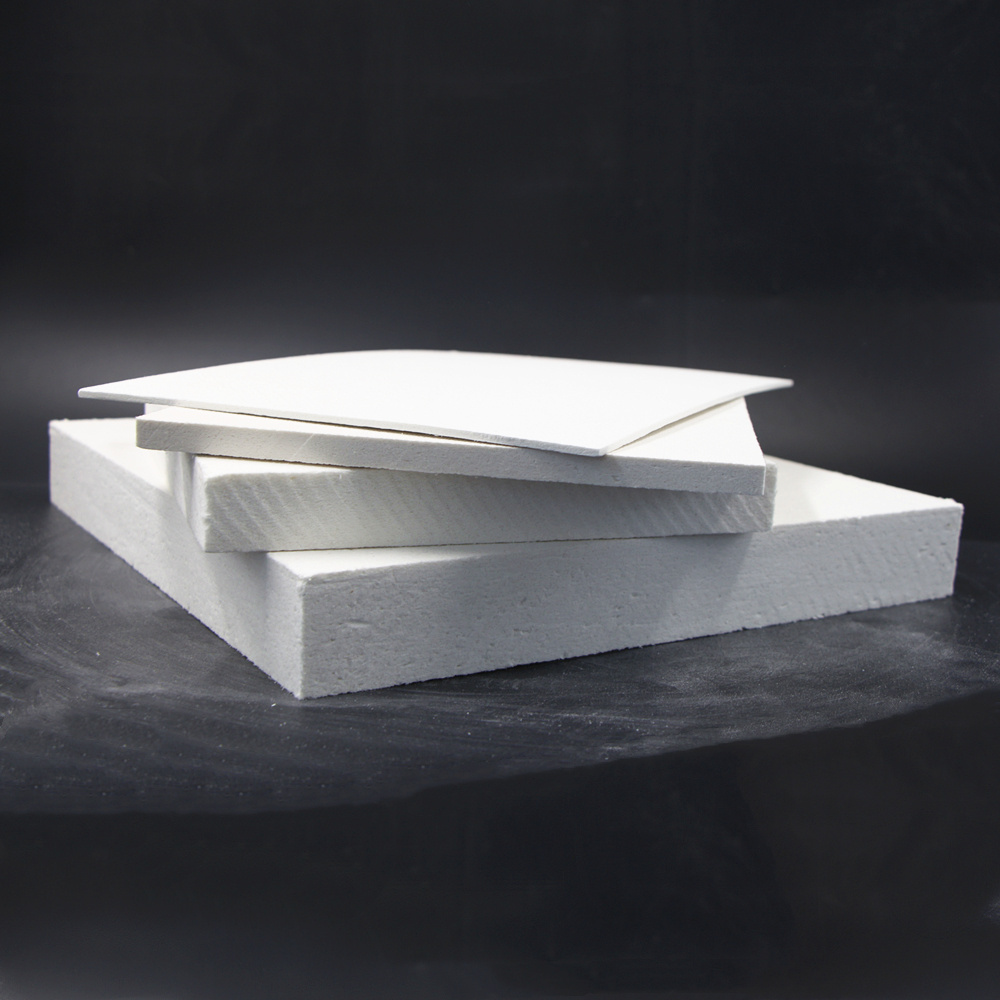

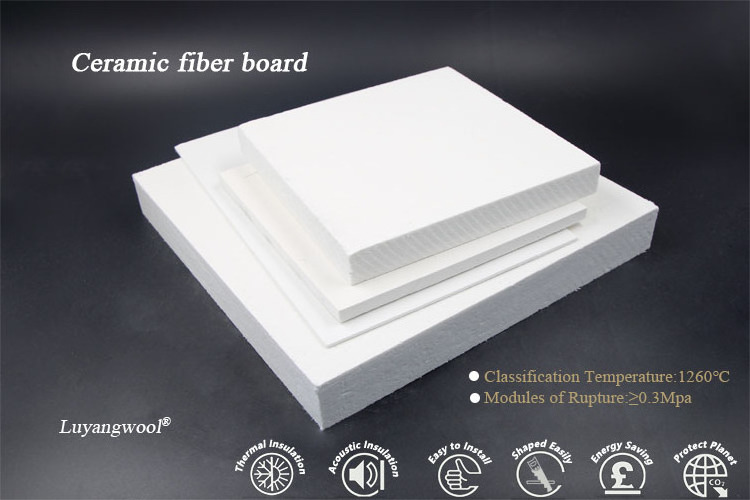

LUYANGWOOL® CERAMIC FIBER BOARD / RCF Board

Luyangwool® ceramic fiber board is manufactured in a wet forming process using Luyangwool®

ceramic fiber bulk and binders.

Luyangwool® ceramic fiber board is designed for insulation applications experiencing vibration, mechanical stress and erosive forces.

Luyangwool® ceramic fiber board can reduce energy costs and cycling times due to high insulating capability, as well as serving to protect refractory surfaces from thermal shock and chemical attack.

Features

*Excellent thermal shock resistance

*Can be machined, cut and shaped easily

*High rigidity and light weight

*Low thermal conductivity

*Low heat storage

*Can be machined, cut and shaped easily

*High rigidity and light weight

*Low thermal conductivity

*Low heat storage

|

Product name

|

LUYANGWOOL® ceramic fiber board (aluminium silicate fiber board)

|

|

Classification temperature

|

1260℃ (2300℉)

|

|

Working

temperature

|

1000℃(1832℉)

|

|

Density

|

250kg/m3, 300kg/m3, 350kg/m3

|

|

Size

|

1200/1000/900/600*1000/600/500/300*10-50mm

Board size can be customized. |

|

Package

|

1.Packed on pallet

2.inner plastic bag, outside carton box

3.inner plastic bag, outside carton box, then packed on pallets

|

|

Payment

|

T/T,L/C,D/A,D/P,Western Union,MoneyGram

30% deposits, 70% balance before delivery

Payment method can be negotiated. |

|

MOQ

|

1 Piece

|

|

Sample

|

We supply small samples for free !

|

|

Delivery time

|

3 days for common shape samples;

10 days for special shape samples;

7-15 days for batch goods.

|

Typical Parameters

|

Description

|

LUYANGWOOL®

STD BOARD

|

LUYANGWOOL®

HP BOARD

|

LUYANGWOOL®

HA BOARD

|

LUYANGWOOL®

HZ BOARD

|

||||

|

Classification Temperature (℃ )

|

1260

|

1260

|

1350

|

1430

|

||||

|

Color

|

White

|

White

|

White

|

White

|

||||

|

Density (kg/m³)

|

250/300/360

|

250/300/360

|

300/360

|

300/360

|

||||

|

Modules of Rupture (MPa)

|

≥0.3

|

≥0.3

|

≥0.3

|

≥0.3

|

||||

|

Compressive Strength (MPa, 10% relative deformation)

|

0.15/0.25/0.3

|

0.25/0.3

|

0.25/0.3

|

0.25/0.3

|

||||

|

Loss of Ignition (%)

|

≤6

|

≤6

|

≤6

|

≤6

|

||||

|

Permanent Linear Shrinkage (%)

|

1000℃ x 24h

≤3.0

|

1100℃ x 24h

≤3.0

|

1200℃ x 24h

≤3.5

|

1350℃ x 24h

≤3.5

|

||||

|

Thermal Conductivity (W/m·K)

|

|

|

|

|

||||

|

400℃

|

0.08

|

0.07

|

0.07

|

0.07

|

||||

|

600℃

|

0.11

|

0.10

|

0.10

|

0.09

|

||||

|

800℃

|

0.14

|

0.14

|

0.13

|

0.13

|

||||

|

1000℃

|

0.19

|

0.19

|

0.19

|

0.18

|

||||

Application

|

Typical Applications

|

Typical Applications

|

|

|

1

|

Furnace hot face lining in petrochemical furnace

|

|

|

2

|

Furnace hot face lining in ceramic kiln

|

|

|

3

|

Board over blanket hot face lining

|

|

|

4

|

Back-up insulation to brick & castable

|

|

|

5

|

Expansion joints

|

|

|

Industry

|

Application

|

|

Cement industry

|

kiln back lining thermal insulation

|

|

Ceramic industry

|

lining of various kilns for thermal insulation, Kiln door, kiln car and dilatation joint, etc,.

|

|

Petrochemical and metallurgy industries

|

Heat treatment furnace kiln back lining thermal insulation, mechanic and metallurgy heating furnace, thermal treatment furnace and others industrial furnace and hot face internal lining

|

|

Glass industry

|

Glass kiln lining and back lining thermal insulation

|

|

Aluminium industry

|

reduction cell firebricks back linings, high temperature reaction, heating device-wall lining and back linings

|

Production Line

Packing & Delivery

Hot Searches