- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM/ODM

-

Model Number:

-

XZT-hailong-20Ah

-

Battery Size:

-

368*109*90mm

-

Place of Origin:

-

China

-

Weight:

-

6.1KG

-

Electric Energy:

-

960 Wh

-

Battery Type:

-

NCM

-

Single Cell Cycle life:

-

500 Cycles

-

Certificate:

-

CE/CB/RoHS/UN38.3/MSDS/ISO 9001

-

Warranty:

-

1 Year

Quick Details

-

Storage Type:

-

Store at -20~ 50℃

-

Anode Material:

-

NCM

-

Application:

-

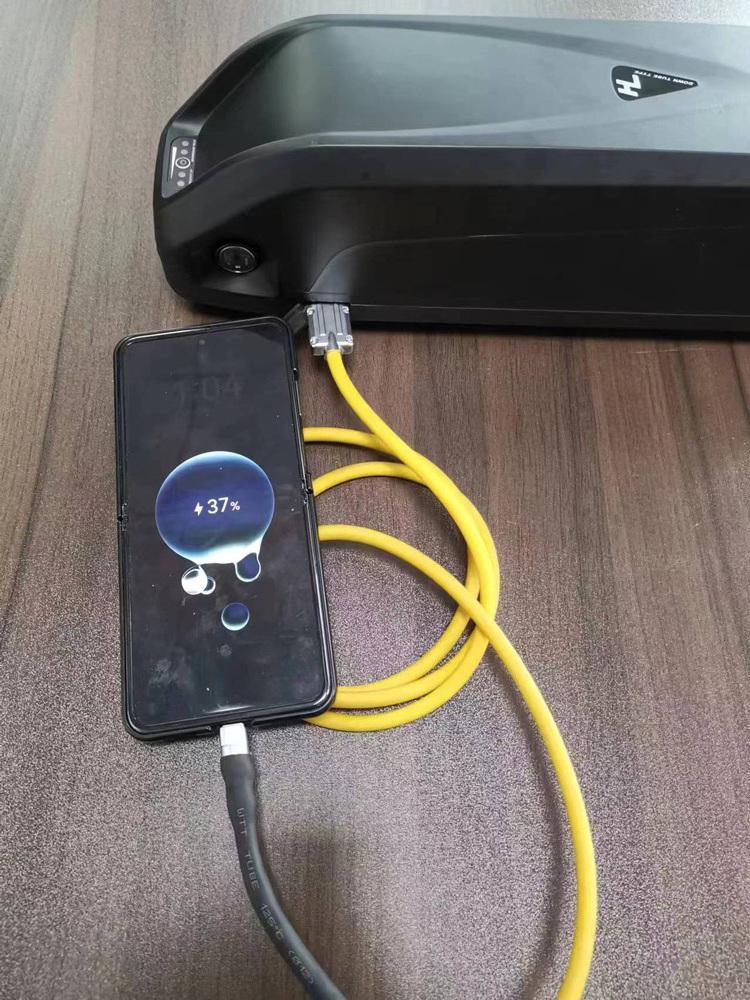

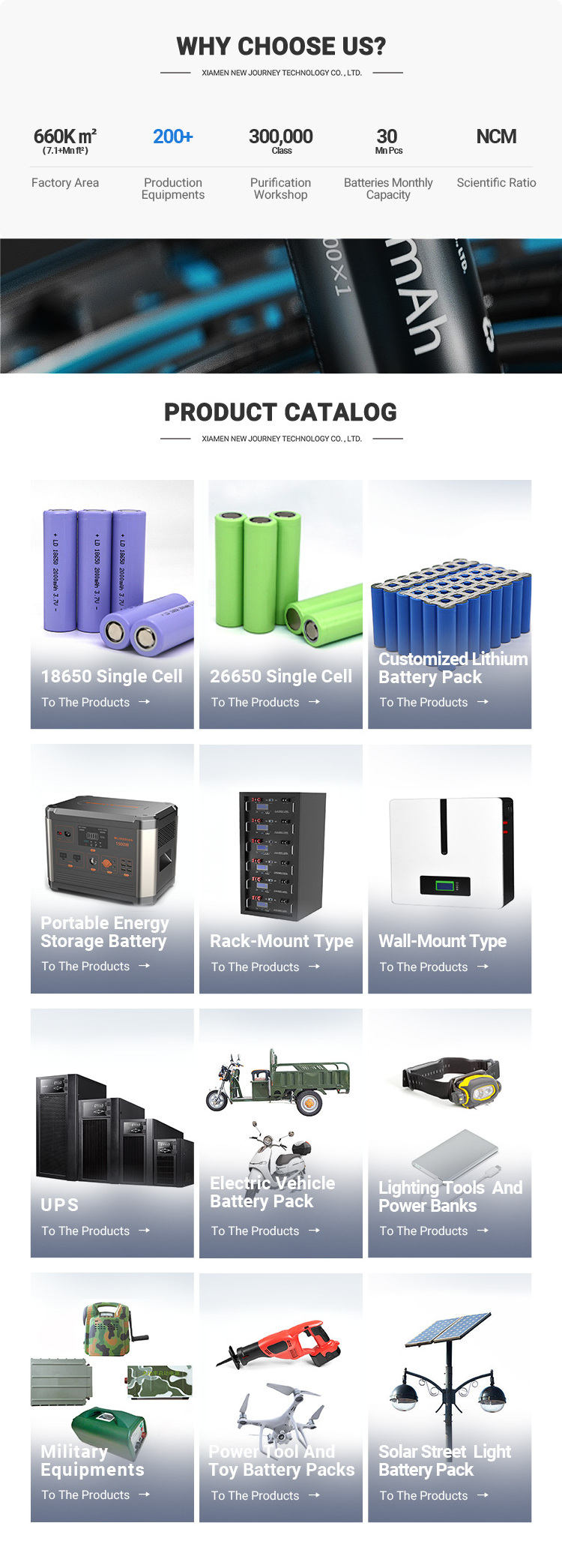

Power Tools, Home Appliances, Consumer Electronics, BOATS, Golf Carts, SUBMARINES, Electric Bicycles/Scooters, electric vehicles, Electric Wheelchairs, Electric Power Systems, Solar Energy Storage Systems, Uninterruptible Power Supplies, Electric Forklifts

-

Brand Name:

-

OEM/ODM

-

Model Number:

-

XZT-hailong-20Ah

-

Battery Size:

-

368*109*90mm

-

Place of Origin:

-

China

-

Weight:

-

6.1KG

-

Electric Energy:

-

960 Wh

-

Battery Type:

-

NCM

-

Single Cell Cycle life:

-

500 Cycles

-

Certificate:

-

CE/CB/RoHS/UN38.3/MSDS/ISO 9001

-

Warranty:

-

1 Year

Products Description

|

Max recommended charge and

discharge cell body temperature |

Charge:0~ 45℃

Discharge::—20~ 60℃

|

|

Maximum short term allowable charge and discharge cell body temperature Charging and discharging at these conditions will shorten cell cycle life.

|

Charge:60℃

Discharge:75℃

|

|

Certification

|

CE/CB/RoHS/UN38.3/MSDS/ISO 9001

|

Our Cells' Testing Report

|

e.g. MODEL:18650 2500mAh

(Contact us to get your expect model testing report)

|

|

|

|

|

||||

|

Ⅰ. Electronic Performance

|

|

|

|

|

||||

|

NO.

|

ITEM

|

Standard

|

|

TESTING METHOD

|

||||

|

1

|

Discharge rate capability (Room temperature)

|

The charging and discharge cures must be smooth

|

|

Charge as described in 2.2, rest for 10min; and discharge with different constant currents and cut off at 2 75V

|

||||

|

|

|

0.2C

|

≥100%

|

|

||||

|

|

|

0.5C

|

≥99%

|

|

||||

|

|

|

1C

|

≥95%

|

|

||||

|

|

|

2C

|

≥95%

|

|

||||

|

|

|

3C

|

≥95%

|

|

||||

|

|

|

5C

|

≥93%

|

|

||||

|

2

|

Cycle life

|

500 Cycles

|

|

Each cycle is an interval between the charge (charge current 0.5C) at 25+3℃, rest 10minutes, and discharge (discharge current 3C) with 2.75V cut-off, then rest 10 minutes. After 500 cycles, Capacity Retention =Cap(500th)/Cap(Av10)≥80%

|

||||

|

3

|

High-Low temperature discharge performance

|

-20℃

|

≥70%

|

Charge as described in 2.2, discharge to2.75V with current of 0.2C, and record the initial capacity. Charge as described in 2.2 rest for 2h in the environment with -20℃、25℃、55℃ (Rest for 4h at -20℃),and Charge as described in 2.2, discharge to2.75V with current of 0.2C, and record the initial capacity. Charge as described in 2.2rest for 2h in the environment with -20℃C、25℃、55℃(Rest for 4h at -20℃),and discharge to 2.75V with the current of 0.2C (Discharge to 2.5V at -20℃). Calculate the ratio of above discharge capacities to the initial capacity

|

||||

|

|

|

-10℃

|

≥80%

|

|

||||

|

|

|

0℃

|

≥80%

|

|

||||

|

|

|

25℃

|

≥100%

|

|

||||

|

|

|

55℃

|

≥95%

|

|

||||

|

4

|

Normal Storage

|

Retention capacity ≥90%* initial capacity

|

|

Tested the initial condition and initial capacity of battery. Store at 25 ± 2 ℃ for 28 days after standard charged, tested the final condition of battery. Then discharge at 0.5C to the discharge cut-off voltage 2.75 V, tested the residual capacity of battery. 0.5C/0.5C tested the recovery capacity of battery. Charge/discharge cycle can be conducted for3 times before meeting the standards

|

||||

|

|

|

Recover capacity ≥95%* initial capacity

|

|

|

||||

|

5

|

High temperature Storage test

|

Retention capacity≥85%* Nominal capacity

|

|

Tested the initial condition and initial capacity of battery. Store at 55+2℃ for 7 days after standard charged, tested the final condition of battery, then discharge at 0.5C to the discharge cut-offvoltage2.75 V, tested the residual capacity of battery. 0.5/ C0.5C tested capacity the recovery battery. Charge/discharge cycle can be conducted for 3 times before meeting the standards

|

||||

|

|

|

Recover capacity≥90%*Nominal capacity

|

|

|

||||

|

Ⅱ. Environmental characteristics

|

|

|

|

|

||||

|

NO.

|

ITEM

|

Standard

|

|

TESTING METHOD

|

||||

|

1

|

Temperature cycle test

|

No leakage,fire,explosion

|

|

Standard charge. Put the battery into20+5℃ chamber: raising the chamber temperature to75+2'℃ for 6h ; reducing the chamber temperature to-40+2℃ for 6h; charge the temperature within 30 minutes; repeating the sequence for 10 cycles;

|

||||

|

2

|

Drop

|

No leakage, fire, explosion

|

|

After standard charge ,cells dropped from aheight of 1.5m to the cement floor

|

||||

|

3

|

Vibration

|

No leakage, fire, explosion

|

|

After standard charge , cells are fixed on vibration table and subjected to vibration cycling at the rate of 1 Hz per minute between 10 Hz to 55 Hz. The excursion of the vibration is 1.52mm. The test has to be carried out for 90 minutes at x,y,z axes individually

|

||||

|

Ⅲ. Safety Characteristics

|

|

|

|

|

||||

|

NO.

|

ITEM

|

Standard

|

|

TESTING METHOD

|

||||

|

1

|

Over discharge

|

No leakage, fire, explosion

|

|

A discharged cells are subjected to a reverse charge at 1C for 90 min.

|

||||

|

2

|

Overcharge

|

No fire, explosion

|

|

After standard charge, after standard charge, continue to charge with a constant current1C/10Vper a cell, holding 1h.

|

||||

|

3

|

Short-circuit

|

No fire, explosion

|

|

After standard charge, Cells are stored in temperature of 20±5℃ and 55+5℃, Then short-circuited by connecting the positive and negative terminals with a total external resistance of 80±20mΩ, remain for 24h or the case temperature declines by 20% of the maximum

temperature rise. |

||||

|

4

|

Crush

|

No fire, explosion

|

|

After standard charge, Placed the cell in two iron plane moulds , with the most strongly13+1KN pressure for the moment compression. Once the maximum force has been applied, or an abrupt voltage drop of one-third of the original voltage has been obtained, or 10% of deformation has occurred compared to the initial dimension, the force is released

|

||||

|

5

|

Low-pressure

|

No leakage, fire, explosion

|

|

After standard charge, Put cell into the low pressure box, adjust the air pressure in the test chamber is 11.6 KPa, temperature to room temperature, let stand for 6 h.

|

||||

|

6

|

Seawater soak

|

No leakage, fire, explosion

|

|

After standard charge, cells immersed in3.5% NaCl solution (mass fraction, simulation under the normal temperature water composition) simulation under the normal temperature water composition in 2h, The cell completely submerged in water

|

||||

Hot Searches