- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Manufacturer Custom A356 T6 Aluminum Die Cast Enclosure

-

Material:

-

aluminum ZL101,A356, A360 AC2C or as customer's requirements

-

Process:

-

Permanent casting,Pressure Die Casting

-

Heat Treatment:

-

T5-T6

-

Drawing Format:

-

pdf,stp,step,stl,etc

-

Surface Finished:

-

Sandblasting, painting, polishing or as customer's requirements

-

Certificate:

-

ISO

-

Weight:

-

0.05kg~20kg for aluminum die cast enclosure

-

Package:

-

Big Plastic Bag Inside,Multilayer Wooden Box outside

-

Delivery time:

-

For sample about 45 days of aluminum die cast enclosure

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Matech Industry

-

Model Number:

-

aluminum die cast enclosure

-

Product name:

-

Manufacturer Custom A356 T6 Aluminum Die Cast Enclosure

-

Material:

-

aluminum ZL101,A356, A360 AC2C or as customer's requirements

-

Process:

-

Permanent casting,Pressure Die Casting

-

Heat Treatment:

-

T5-T6

-

Drawing Format:

-

pdf,stp,step,stl,etc

-

Surface Finished:

-

Sandblasting, painting, polishing or as customer's requirements

-

Certificate:

-

ISO

-

Weight:

-

0.05kg~20kg for aluminum die cast enclosure

-

Package:

-

Big Plastic Bag Inside,Multilayer Wooden Box outside

-

Delivery time:

-

For sample about 45 days of aluminum die cast enclosure

SINCERITY QUALITY COMPETENCE

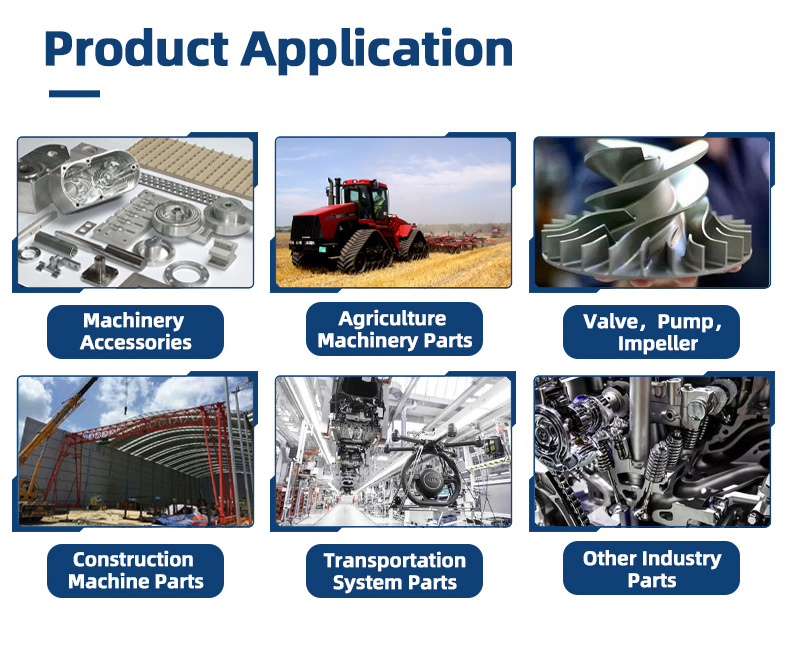

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

Die casting

is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, you need to use a cold chamber die casting machine or a hot chamber die casting machine.

The cost of casting equipment and molds is high, so the die-casting process is generally only used for mass production of a large number of products. Manufacturing die-cast parts is relatively easy, which generally only requires four main steps, and the individual cost increment is very low. Die casting is particularly suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used one among various casting processes. Compared with other casting technologies, the die-casting surface is flatter and has a higher dimensional consistency.

|

Product Name

|

Manufacturer Custom A356 T6 Aluminum Die Cast Enclosure

|

|

|

|

|||

|

Main blank Process

|

Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting,

High Pressure Casting/Sand Casting, etc. |

|

|

|

|||

|

Blanks Tolerance -Casting Tolerance

|

CT4-6 for Permanent Molding, Die Casting. CT 9-11 for Sand Casting

|

|

|

|

|||

|

Applicable Material for Aluminum casting

|

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2, Or according to customer requirements

|

|

|

|

|||

|

Casting Blank Size /Dimensions

|

2 mm-1500mm / 0.08inch-60inch , or according to customer requirements

|

|

|

|

|||

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

|

|

|

|||

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

|

|

|

|||

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

|

|

|

|||

|

Applicable Heat Treatment

|

T5~T6

|

|

|

|

|||

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating,

Finish Painting, Anodize (White or Black Color), as customers request. |

|

|

|

|||

|

Lead Time

|

About 50 days for aluminum die cast enclosure

|

|

|

|

|||