- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±1%

-

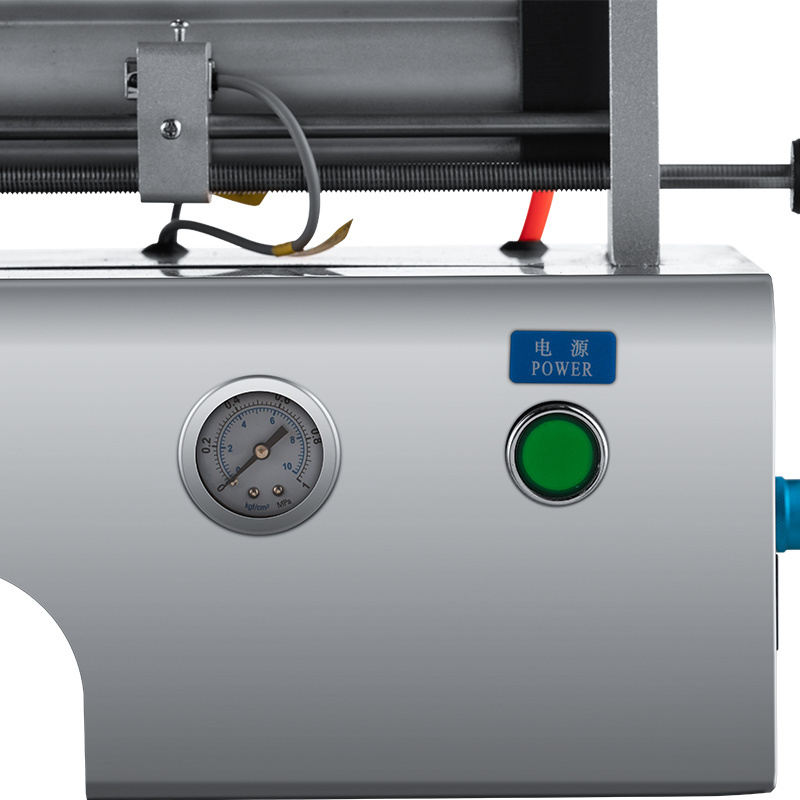

Voltage:

-

220/380v

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OUXIN

-

Dimension(L*W*H):

-

760*220*630 mm

-

Weight:

-

20 KG

-

Function:

-

pillow filling machine

-

Name:

-

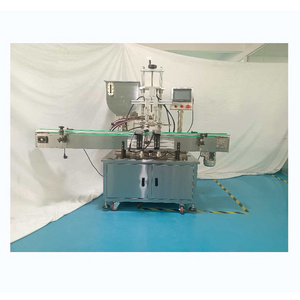

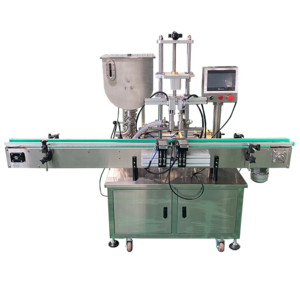

Water Washing Filling Capping Machine

-

Usage:

-

Beverage Filling Packaging

-

Material:

-

Stainless Steel

-

Filling range:

-

10-999g

-

Keywords:

-

Fillng Machine

-

Advantage:

-

Automatic Working

-

Power supply:

-

220V/110V

-

After-sales Service Provided:

-

2 Years

Quick Details

-

Machinery Capacity:

-

1800BPH

-

Packaging Material:

-

Glass

-

Filling Material:

-

GLUE

-

Filling Accuracy:

-

≤±1%

-

Voltage:

-

220/380v

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OUXIN

-

Dimension(L*W*H):

-

760*220*630 mm

-

Weight:

-

20 KG

-

Function:

-

pillow filling machine

-

Name:

-

Water Washing Filling Capping Machine

-

Usage:

-

Beverage Filling Packaging

-

Material:

-

Stainless Steel

-

Filling range:

-

10-999g

-

Keywords:

-

Fillng Machine

-

Advantage:

-

Automatic Working

-

Power supply:

-

220V/110V

-

After-sales Service Provided:

-

2 Years

Product Description

|

Model

|

OX-WYD60

|

OX-WYD70

|

|

|

Voltage

|

220V/50HZ

|

220V/50HZ

|

|

|

Rated Power

|

50W

|

50W

|

|

|

Packing Speed

|

1-25bottle/min

|

1-25bottle/min

|

|

|

Weighing Range

|

10-100ml

|

10-500ml

|

|

|

Error Range

|

About 2g

|

|

|

|

Filling precision

|

≤± 1%

|

≤± 1%

|

|

|

Machine Size (mm)

|

760*220*630

|

760*220*630

|

|

|

Machine Weight

|

20kg

|

20kg

|

|

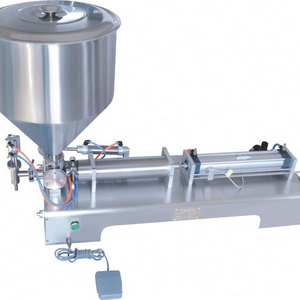

The horizontal single head hopperless liquid automatic filling and packaging machine is made of stainless steel, with stable performance, low consumption, high efficiency, safety and cleanliness. It is ideal for filling and packaging all kinds of liquids and is widely used in the food and pharmaceutical industries.

What are the features of our horizontal single head hopperless liquid filling and packaging machine?

1. All stainless steel material, food grade, energy saving.

2. Intelligent control, fully automatic packaging, more accurate and faster.

3. Suitable for packing almost all kinds of liquids (not suitable for high viscosity liquids, must be free of particles).

4. Split design, high efficiency, low noise, smooth machine operation.

5. Easy to operate and maintain.

6. Roll materials: plastic film, laminated film, aluminium foil and other heat sealable composites.

Translated with www.DeepL.com/Translator (free version)

Hot Searches