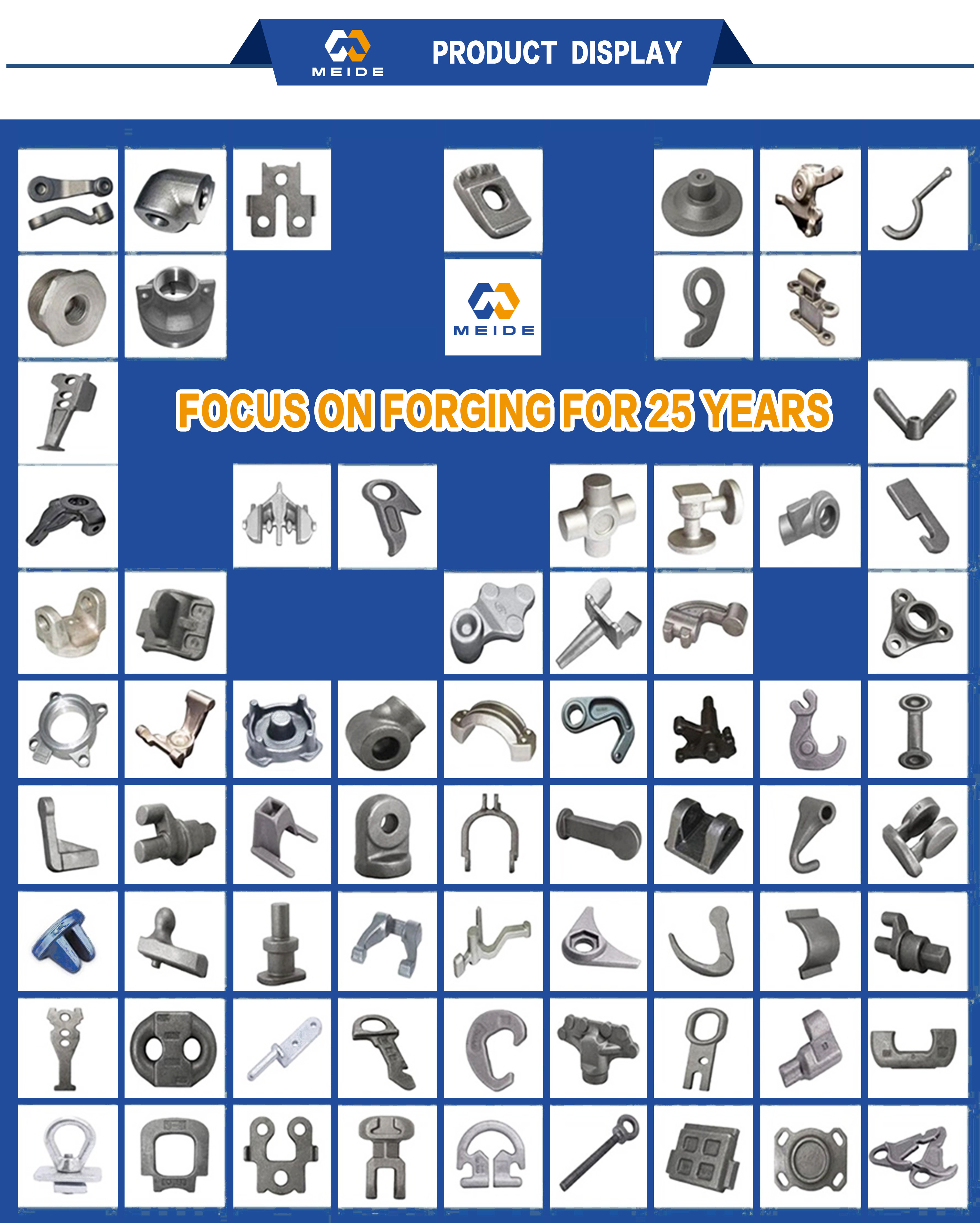

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Copper aluminum steel stainless steel titanium

-

Product name:

-

Forging Metal Parts

-

MOQ:

-

10 Piece

-

Keyword:

-

OEM Hot Forging Parts

-

Application:

-

Industry

-

Surface treatment:

-

Polishing

-

Service:

-

OEM\ODM

-

Process:

-

Forging+Machining(if Need)+surface Treatment

-

Certificate:

-

ISO9001

-

Size:

-

Customer's Requst

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Meide

-

Model Number:

-

customization

-

Material:

-

Copper aluminum steel stainless steel titanium

-

Product name:

-

Forging Metal Parts

-

MOQ:

-

10 Piece

-

Keyword:

-

OEM Hot Forging Parts

-

Application:

-

Industry

-

Surface treatment:

-

Polishing

-

Service:

-

OEM\ODM

-

Process:

-

Forging+Machining(if Need)+surface Treatment

-

Certificate:

-

ISO9001

-

Size:

-

Customer's Requst

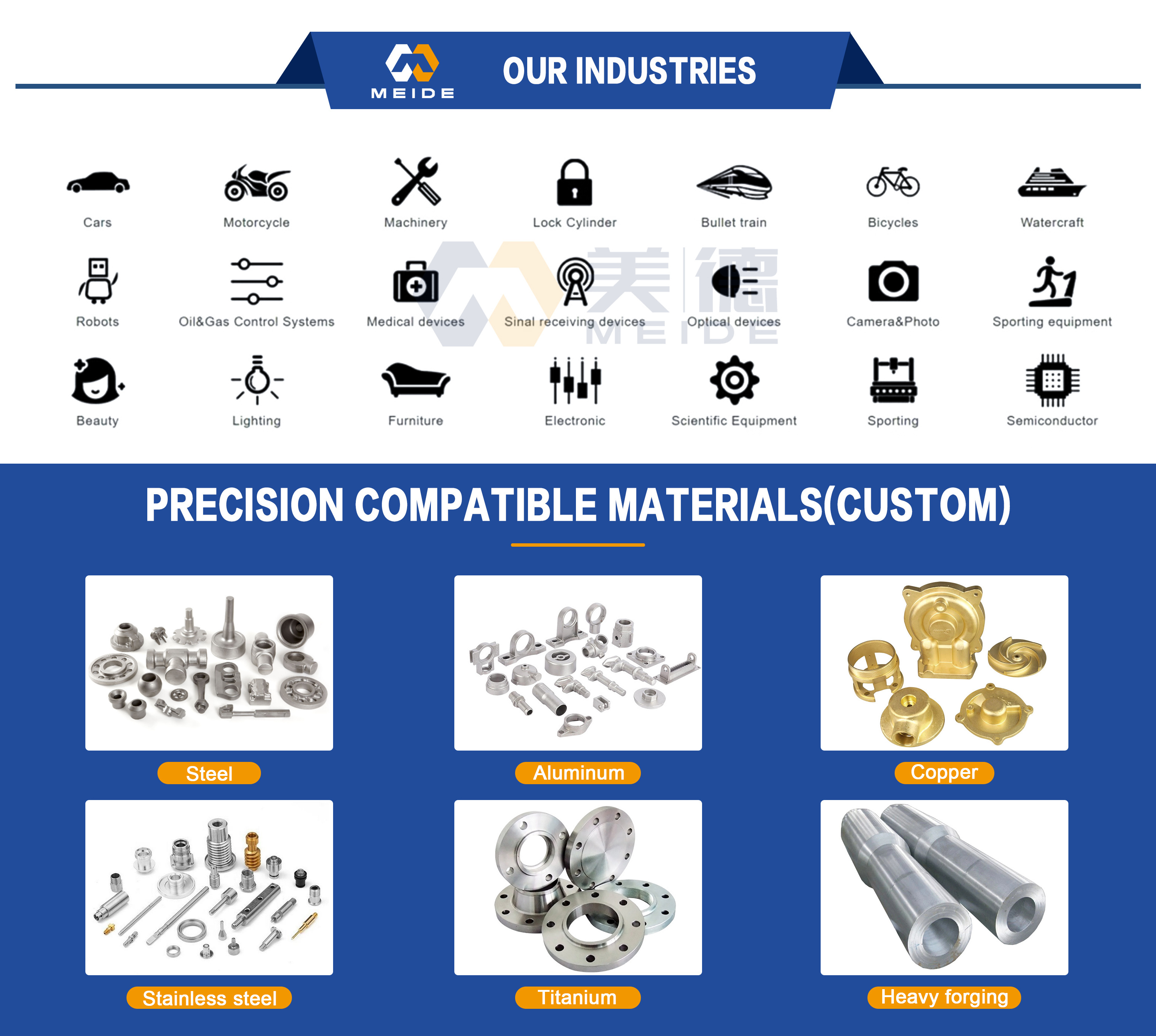

Product Description

|

Materials

|

Carbon steel,Alloy steel, stainless steel and high temperature alloy, aluminum alloy, titanium alloy and so on.

|

|

Roughness

|

Ra0.08-0.2

|

|

Melting process

|

EF+LF+VD

|

|

Production process

|

Forging+heat treatment+rough machining+QT+finish machining

|

|

Forging

|

Open die forging (product range: Max length 16000mm; Max weight 35 Mt)

|

|

Treatment

|

Carburizing and phosphating

|

|

Heat Treatment

|

Normalizing, Tempering, Annealing, Q + T (Quenching and Tempering)

|

|

Machining

|

Pre-machining, Finish machining

|

|

Surface Finishing

|

Sand blasting, Coating, Painting

|

|

Forging ratio

|

≥3.5

|

|

Applicalbe standard

|

ASTM,ASME,DIN,JIS,ISO,BS,API,EN

|

|

Executive standard

|

JB/GB/EN/DIN/JIS/ASME/ASTM/ISO

|

|

Certification authorities

|

ISO9001:2008,ISO14001,TÜV(BV),(LR),ABS,RINA,(GL),(KR),(DNV),(NK),PED.

|

|

Delivery terms

|

Rough machining(N+T);finish machining(Q+T),nitriding quenching

|

|

Delivery

|

Samples are sent by express

Large quantity products delivered to customer by sea or according to your request |

|

Produce Equipment

|

Friction Screw Press Series, CNC Lathe, Machining Center

(Vertical Spindles), CNC Milling Machine, Bench Drilling Machine, Heat Treatment Equipments and so on. |

|

Forging equipment

|

6000T open die hydropress

|

|

Surface treatment

|

Heat treatment, Polishing, shot blasting,

Painting, Electro-plating, Chemical Plating, |

|

Test machine

|

spectrograph,ut device,tensile and compact test machine,metalloscope,outside micrometer,bore dial indicator,trilinear coordinatre

measuring machine,hardness test machine,metallurgical analysis, tensile strength tester, hardness tester, altimeter, scale micrometer, pressure tester, etc. |

|

Wind Turbine Shaft

|

4140,42CrMo4,34CrNiMo6

|

|

Wind Tower Flange

|

S355NL,C22,16Mn,20Mn,42CrMo,F304

|

|

Shaft Forgings

|

25CrMo4,42CrMo4,40CrNiMo,34CrNi3Mo,25Cr2Ni4MoV, 18CrNiMo5,30CrMo,4130,4140.

|

|

Gear Forgings

|

35CrMo,34CrMo4,4137,42CrMo,4140,SCM440,20CrMnMo, 40CrNiMo,20CrNi2Mo,20Cr2Ni4A,34CrNi3Mo.

|

|

Marine Forgings

|

20Mn,50Mn, C45,42CrMo,20MnMo,CK45,34CrNi1Mo

|

|

Pressure Vessel Forgings

|

SA105,SA350 LF2,16Mn,20MnMo,15MnMo,12Cr2Mo1, 14Cr1Mo,F304,F316,17-4PH

|

|

Forged tube sheet

|

SA106 CL B,SA106 CL C,WB36,12Cr1MoV,

SA335 P11,P12,P22,P91,SA182 Gr.F1,Gr.F5, Gr.F11 CL2,Gr.F12CL2,Gr.F22CL3,SA350Gr.LF1,Gr.LF2,Gr.LF3 |

|

Application series

|

Representative steel type

|

|

Description

|

|

|

Petroleum machinery series

|

AISI4150,AISI4140,AISI4130, 30CrMo,4145H

|

|

Valve body, valve block, drill pipe, drill collar

|

|

|

Tool mold series

|

1.2714,5CrMnMo,5CrNiMoV, 1.2738,1.2311,1.2312

|

|

Die casting mold, forging mold,

|

|

|

|

|

|

plastic mold

|

|

|

Bearing series

|

52100,GCr15,SUJ2

|

|

Bearing ring, rolling bearing, piston rod

|

|

|

Marine series

|

4140,42CrMo,SCM440, 709M40

|

|

Marine accessories

|

|

|

Car series

|

SAE8620,20CrNiMo, SNCM220

|

|

Crankshaft,gear

|

|

|

Heavy-

duty transmission series |

40CrNiMo,SNCM439, SAE4340,EN24

|

|

Port transmission parts,

helicopter rotor shaft, turbine shaft |

|

|

Mining machinery series

|

655M13,826M40,

25CrMo |

|

Mining bit, carburizing and crushing machinery

|

|

|

Wind power gear series

|

18CrNiMo7-6,17CrNiMo6, 1.6582,1.6587,SAE8620

|

|

Meet the design life of more than 20 years

|

|

|

Wind power spindle series

|

34CrNiMo6,817M40

|

|

Meet the design life of more than 20 years

|

|

|

Nitriding series

|

20MnCr5,38CrMoAl, 31CrMoV9

|

|

Gear, injection molding machine screw / barrel,precision components

|

|

|

Pressure vessel series

|

15CrMo,13CrMo4-4

|

|

Boiler, petrochemical hydrogenation vessel accessories

|

|

|

Metallurgical roll series

|

21CrMoV511,W1.7225,EN19,709M40

|

|

Steel rolling roll

|

|

Forging Production Flow

1. Enquiry With Drawing In Details

2. Confirm Steel Material, Chemical Compositions, Mechanical Properties, Tolerances

3. Confirm Payment Terms, Order Materials or Check Material in Stock

4. Check Material Chemical Compositions, Material Weight, Dimensions

5. Cut Materials, Record Weight, Pre-Heating For Forging

6. Forging Ratios, Heat Treatment After Forging, Dimension Check

7. Rough Machining, UT Test, Heat Treatment

8. Fine Machining, UT & PT Test, Dimensions Inspection, Mechanical Properties Test

9. Customer Inspection at Site, Packing, Delivery Arrangement

10. Balance Payment Confirmation, Dispatch Forgings or Casting

11. Bill of Loading Confirmation, MTC Dispatch, Customs Clearances

12. Order Accomplished!!!

Product Packaging

1. Enquiry With Drawing In Details

2. Confirm Steel Material, Chemical Compositions, Mechanical Properties, Tolerances

3. Confirm Payment Terms, Order Materials or Check Material in Stock

4. Check Material Chemical Compositions, Material Weight, Dimensions

5. Cut Materials, Record Weight, Pre-Heating For Forging

6. Forging Ratios, Heat Treatment After Forging, Dimension Check

7. Rough Machining, UT Test, Heat Treatment

8. Fine Machining, UT & PT Test, Dimensions Inspection, Mechanical Properties Test

9. Customer Inspection at Site, Packing, Delivery Arrangement

10. Balance Payment Confirmation, Dispatch Forgings or Casting

11. Bill of Loading Confirmation, MTC Dispatch, Customs Clearances

12. Order Accomplished!!!

Product Packaging

FAQ

Q1: Are you a factory?

A: We are a factory set up more than 25 years ,we accept OEM/ODM orders.

Q2:When can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price .Please call us or tell us in your email so that we reply your inquiry with priority.

Q3: How to custom-made (OEM/ODM)?

A:If you have a new product drawing or a sample .Please send to us ,and we can custom -made the hardware as your required .We will also provide our professional adnices of the products to make the design to be more realized &maximize the performance.

Q4: How should I order and make payment?

A: By T/T ,for sample 100 % with the order ,for production ,30% paid for deposit by T/T before production arrangement,the balance to be paid before shippment.

Q5: What is the delivery time ?

A: Delivery will occur between to 10-15 days after date .Faster delivery time can be arranged if needed.

Hot Searches