- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

yuandong

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

5000*1650*2200mm

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

3500 kg

-

Product Name:

-

Block brick making machine

-

Raw material:

-

River sand, gravel, slag, slag, perlite, fly ash, ceramsite, cement

-

Block Type:

-

concrete blocks, solid/hollow/cellular masonry product/paver stone,ect

-

Mould:

-

Customized by customized need

-

Pallet size:

-

850*550mm or customized

-

Application:

-

Buildings, road pavers, gardens, landscaping, city constructions,etc.

-

Long service life:

-

Precise line cutting and carburizing treatment technology

-

Optional machine:

-

Block machine ,belt conveyor mixer and mold ,trolley

-

Drive type:

-

Electric or diesel or gasoline

-

Material:

-

high quality steel,and precision welding,the hydraulic system

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC), Other

-

Brick Raw Material:

-

sand, cement,dust and coal fly ash,cinder,slag,gangue,perlite, ect

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

yuandong

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

5000*1650*2200mm

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

3500 kg

-

Product Name:

-

Block brick making machine

-

Raw material:

-

River sand, gravel, slag, slag, perlite, fly ash, ceramsite, cement

-

Block Type:

-

concrete blocks, solid/hollow/cellular masonry product/paver stone,ect

-

Mould:

-

Customized by customized need

-

Pallet size:

-

850*550mm or customized

-

Application:

-

Buildings, road pavers, gardens, landscaping, city constructions,etc.

-

Long service life:

-

Precise line cutting and carburizing treatment technology

-

Optional machine:

-

Block machine ,belt conveyor mixer and mold ,trolley

-

Drive type:

-

Electric or diesel or gasoline

-

Material:

-

high quality steel,and precision welding,the hydraulic system

Product Description

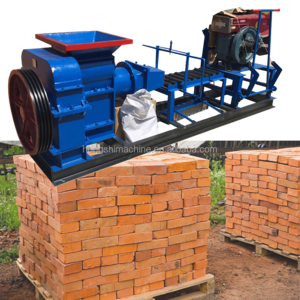

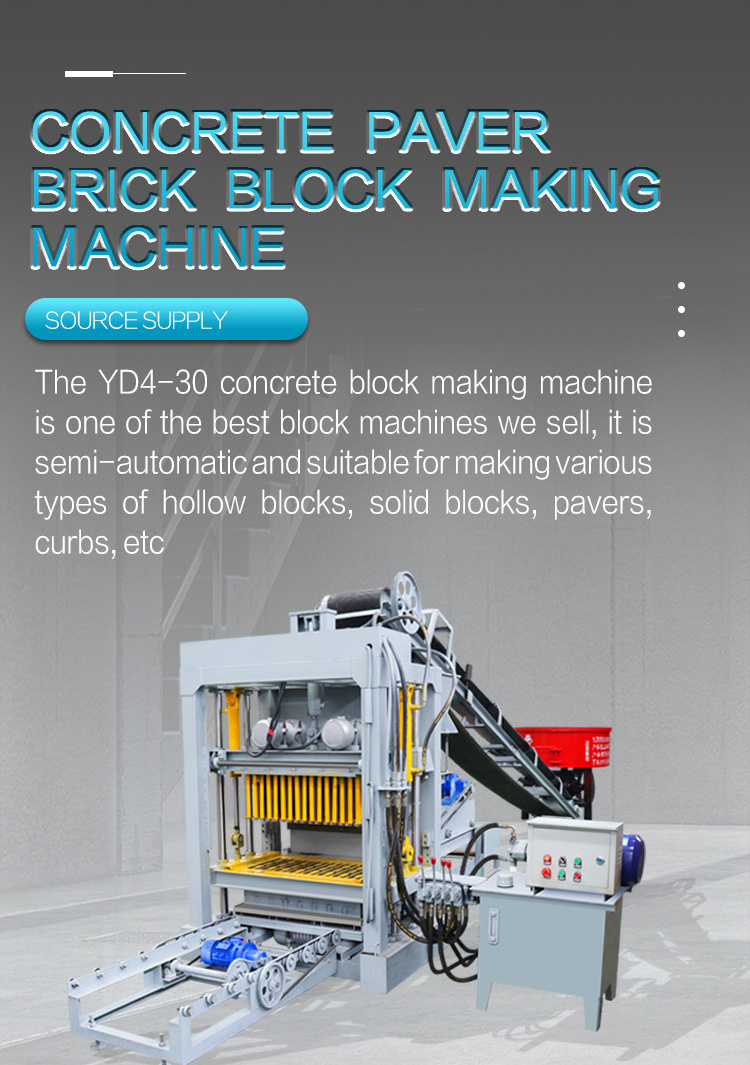

High Performance Electric Cement Brick Making Hollow Concrete Block Maker Machine Price

Block brick making machine is a machine used to make the production of bricks. Brick making is very important especially in the construction sector. That is why these machines are used to make bricks at low cost in a short time. The machines must have a long service life and be of high quality. It is one of the most preferred machines in the construction sector in recent years. There are things to be considered when producing bricks and blocks.

g mac

hine

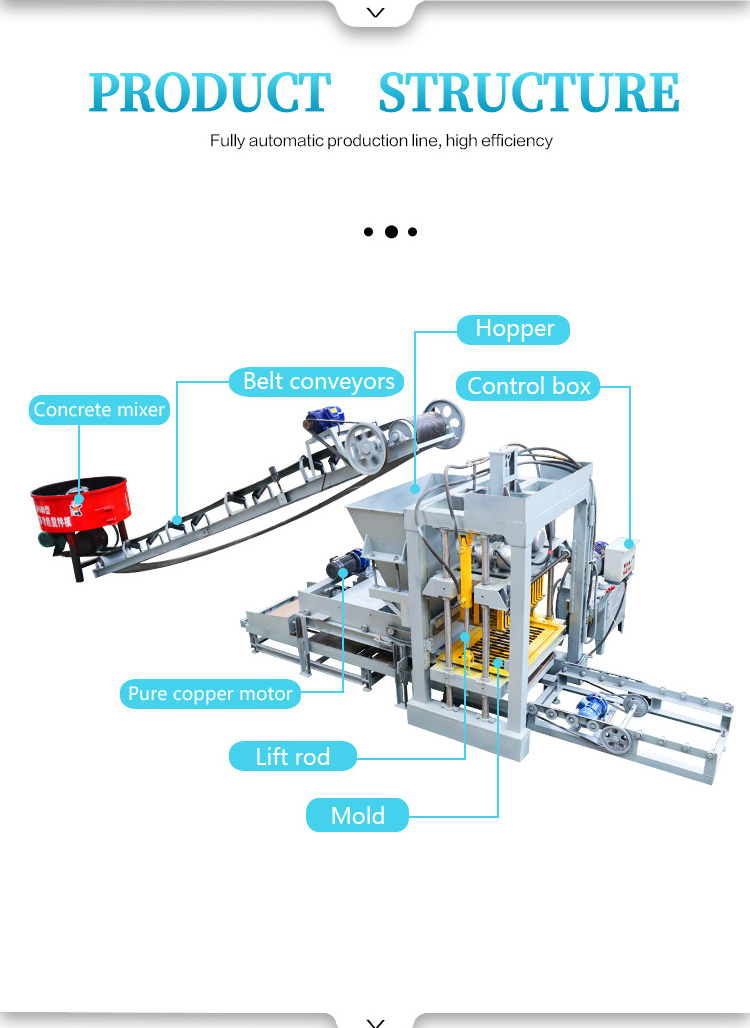

Structure

|

Dimension of host machine

|

1850*1880*2240mm

|

Host machine power

|

13.45kw

|

|

Weight of host machine

|

1.56t

|

vibration force

|

35.5kn

|

|

Molding area

|

830*530mm

|

Mixer model

|

JW500

|

|

Water consumption

|

10-15 ton/day

|

Pallet size

|

850*550*25mm

|

|

Workshop area

|

160㎡

|

Voltage

|

380v/415v/440v

|

Details Images

There are many advantages of block brick machines. In the construction sector, machines are produced by designing with low costs in the short term. Thanks to the advantages it provides, it is preferred by many construction companies.

1. It does not cause any harm to the environment.

2. It makes production in many different designs such as hollow bricks, block bricks, pavement bricks.

3. Machine after-sales technical service services are managed quite well.

4.The brick machine design is reliable, the structure is compact, directional vibration is realized, and the energy consumption is eliminated immediately.

5.Completes the whole brick making process in a short time without requiring labor.

6.The machines are durable and sturdy.

7. Doesn't take up too much space.

8.The prices are quite affordable.

1. It does not cause any harm to the environment.

2. It makes production in many different designs such as hollow bricks, block bricks, pavement bricks.

3. Machine after-sales technical service services are managed quite well.

4.The brick machine design is reliable, the structure is compact, directional vibration is realized, and the energy consumption is eliminated immediately.

5.Completes the whole brick making process in a short time without requiring labor.

6.The machines are durable and sturdy.

7. Doesn't take up too much space.

8.The prices are quite affordable.

Product Display

Applications

Packing And Shipping

Hot Searches