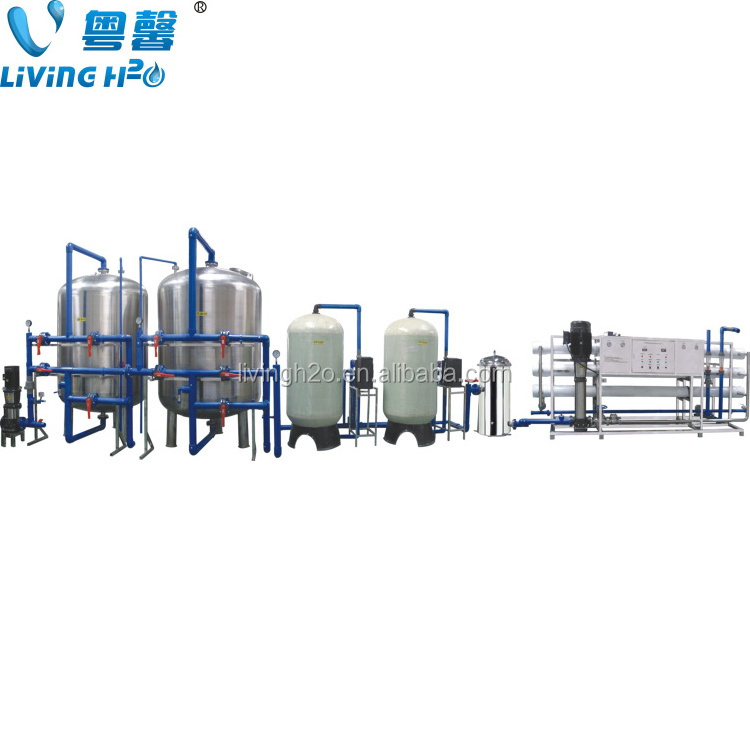

Reverse osmosis water purification machine to treat fresh water for drinking/mineral water. Our plant could make drinking water,

mineral water, pure water and potable water from the water sources: Ground, spring, well, river, borehole, brackish, lake water

and etc.

Raw water source: bore whole, river, well, mountain spring, lake, tap water, etc.

Raw water pump/multi pump: Nanfang, Grundfos etc.

Filter media: Quartz sand filter, active carbon filter, Softener, security filter( PP filter)

RO Membrane: Dow, Hydranautics, Toray, Vontron etc.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

4500

-

Size:

-

L5000W900H1600

-

Power:

-

4.5KW

-

Weight (KG):

-

250 kg

-

style:

-

2000L/H Water Treatment System Reverse Osmosis Drinking

-

Product name:

-

Water Treatment System Processing Reverse Osmosis Plant

-

Usage:

-

Pure Water Process

-

Name:

-

Pure Water Treatment Plant

-

Color:

-

White

-

Application:

-

Filtration

-

Type:

-

Pure Water Treatment System

-

Keywords:

-

RO Water Filtration

-

Function:

-

Producing Fresh Water

-

Use:

-

Water Treatment Technologies

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

living

-

Material:

-

wooden case

-

Weight:

-

4500

-

Size:

-

L5000W900H1600

-

Power:

-

4.5KW

-

Weight (KG):

-

250 kg

-

style:

-

2000L/H Water Treatment System Reverse Osmosis Drinking

-

Product name:

-

Water Treatment System Processing Reverse Osmosis Plant

-

Usage:

-

Pure Water Process

-

Name:

-

Pure Water Treatment Plant

-

Color:

-

White

-

Application:

-

Filtration

-

Type:

-

Pure Water Treatment System

-

Keywords:

-

RO Water Filtration

-

Function:

-

Producing Fresh Water

-

Use:

-

Water Treatment Technologies

Product Description

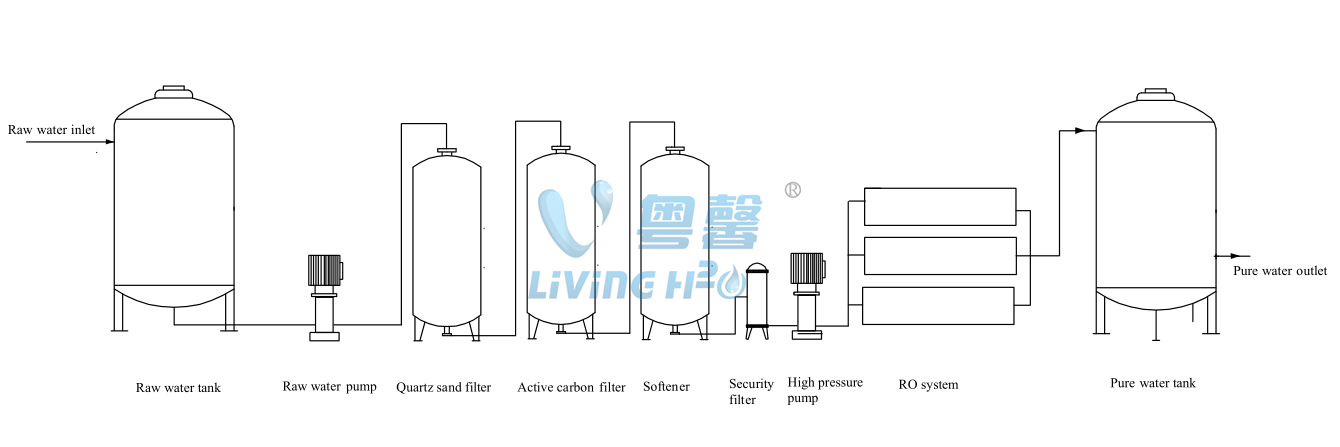

Working process:

1.

Raw water pump

---- provide the pressure to quartz sand filter/active carbon filter.

2. Quartz sand filter ----get rid of turbidity, suspended matter, organic matter, colloid, ect.

3. Active Carbon filter ----Remove the color, free chloride, organic matter, harmful matter, ect.

4. Softener ----exchange "ions" of calcium and magnesium with the most common and easiest method.

5. Security filter ----prevent large particles, bacteria, viruses into RO membrane, accuracy is 5um,

6. High pressure pump ----Provide the high pressure to RO membrane.

7. RO system -----main part of the plant. The RO membrane's desalting rate can reach 99%, removing over 99% ions.

2. Quartz sand filter ----get rid of turbidity, suspended matter, organic matter, colloid, ect.

3. Active Carbon filter ----Remove the color, free chloride, organic matter, harmful matter, ect.

4. Softener ----exchange "ions" of calcium and magnesium with the most common and easiest method.

5. Security filter ----prevent large particles, bacteria, viruses into RO membrane, accuracy is 5um,

6. High pressure pump ----Provide the high pressure to RO membrane.

7. RO system -----main part of the plant. The RO membrane's desalting rate can reach 99%, removing over 99% ions.

Provide stable water source and pressure to the back-end treatment system.

Media filters

● Sand filter

The device filters the impurity substance and disposes of the divalent iron and manganese ion in the raw water. It is equipped

with automatic control valve, which can discharge the sediment by its automatic back washing function.

● Activated carbon filter

This filter removes the colors and smells of the raw water to improve the water’s flavor.

●Water softener

This device soften the water by oxidizing the calcium ion and magnesium ion in the raw water with cation.

The device filters the impurity substance and disposes of the divalent iron and manganese ion in the raw water. It is equipped

with automatic control valve, which can discharge the sediment by its automatic back washing function.

● Activated carbon filter

This filter removes the colors and smells of the raw water to improve the water’s flavor.

●Water softener

This device soften the water by oxidizing the calcium ion and magnesium ion in the raw water with cation.

●Security filter

It with the filtering accuracy of ≤5μm, the precise filter can filter the particle impurity substance in the raw water from the

front-end filters. It can prevent impurity substance from flowing into and thus blocking up the reverse osmosis membrane

system, so as to decrease power consumption more effectively.

front-end filters. It can prevent impurity substance from flowing into and thus blocking up the reverse osmosis membrane

system, so as to decrease power consumption more effectively.

Gives stable water supply and sufficient pressure to the reverse osmosis membrane system.

Main part of the water plant. The RO membrane's desalting rate can reach 99%, removing over 99% ions. It filters the substances

such as bacteria and ions in the water. And the quality of product water after filtration will be much higher than that of

standard daily drinking water.

such as bacteria and ions in the water. And the quality of product water after filtration will be much higher than that of

standard daily drinking water.

Advantages:

Reverse osmosis equipment belongs to physical desalting method, which has many advantages.

1.Non-phase-change physical method was used to desalinate and purify the saline water under normal temperature.

2.Desalting rate of single membrane element is 99.3% and can remove colloid, organics, bacteria, virus and all kinds of heavy metals in water at the same time.

3.With water pressure as the driving force, energy consumption is the lowest among many treatment methods.

4.No need for large amount of chemical treatment, no elimination of chemical waste liquid, no environmental pollution, and the

recovery rate is over 70%.

5.High automation program, automatic stop in case of failure, with automatic protection function.

6.The system is simple, easy to operate, and the water quality is stable.

7.Equipment covers small area, compact structure, reliable operation and high water quality.

1.Non-phase-change physical method was used to desalinate and purify the saline water under normal temperature.

2.Desalting rate of single membrane element is 99.3% and can remove colloid, organics, bacteria, virus and all kinds of heavy metals in water at the same time.

3.With water pressure as the driving force, energy consumption is the lowest among many treatment methods.

4.No need for large amount of chemical treatment, no elimination of chemical waste liquid, no environmental pollution, and the

recovery rate is over 70%.

5.High automation program, automatic stop in case of failure, with automatic protection function.

6.The system is simple, easy to operate, and the water quality is stable.

7.Equipment covers small area, compact structure, reliable operation and high water quality.

Applications:

1. Drinking Water Project: Ultra-pure water, water purification;

2. Beverage Industry: Recipe water, process water, washing with water;

3. Desalination: Island regions, coastal dryland, marine, sea oil and other production and living water;

4. Electric Power Industry: boiler feed water, cooling water;

5.The electronics industry: semiconductor industry ultra-pure water pre-treatment, IC cleaning water, formula with water;

6. Food industry: formula water, process water;

7. The pharmaceutical industry: process water, the formulations with water, washed with water, water for injection, sterile

water was prepared;

8. Chemical industry: process water, wastewater treatment;

9. The petrochemical industry: oil field injection water, petrochemical wastewater treatment;

10. The field of environmental protection: precious metal plating rinse water, water recycling, to achieve zero emissions or

slightly emissions.

2. Beverage Industry: Recipe water, process water, washing with water;

3. Desalination: Island regions, coastal dryland, marine, sea oil and other production and living water;

4. Electric Power Industry: boiler feed water, cooling water;

5.The electronics industry: semiconductor industry ultra-pure water pre-treatment, IC cleaning water, formula with water;

6. Food industry: formula water, process water;

7. The pharmaceutical industry: process water, the formulations with water, washed with water, water for injection, sterile

water was prepared;

8. Chemical industry: process water, wastewater treatment;

9. The petrochemical industry: oil field injection water, petrochemical wastewater treatment;

10. The field of environmental protection: precious metal plating rinse water, water recycling, to achieve zero emissions or

slightly emissions.

Product Paramenters

|

Model

|

Capacity of water (M3/H)

|

General Power (KW)

|

Electrical Power

(50-60Hz)

|

Membrane (Pic)

|

Size (L*W*H)mm

|

Weight (KG)

|

|

RO-300L/H

|

0.3

|

2.75

|

AC220V 18A / 380V 9A

|

ESPA4040*2

|

1550*900*1820

|

150

|

|

RO-500L/H

|

0.5

|

2.75

|

AC220V 18A / 380V 9A

|

ESPA4040*3

|

1550*900*1820

|

250

|

|

RO-700L/H

|

0.7

|

4.25

|

AC220V 27.5A / 380V 13A

|

ESPA4040*4

|

1550*900*1820

|

350

|

|

RO-1000L/H

|

1

|

3.75

|

AC220V 24A / 380V 12A

|

ESPA4040*4

|

1980*900*1940

|

500

|

|

RO-2000L/H

|

2

|

4.75

|

AC380V 8.8A

|

ESPA4040*6

|

4800*700*2050

|

700

|

|

RO-3000L/H

|

3

|

5.75

|

AC380V 10A

|

ESPA4040*7

|

6000*800*2200

|

800

|

|

RO-4000L/H

|

4

|

7.5

|

AC380V 12A

|

ESPA4040*8

|

7000*900*2400

|

1000

|

|

RO-5000L/H

|

5

|

12.5

|

AC380V 25A

|

ESPA8040*9

|

8000*1000*2700

|

1500

|

|

RO-6000L/H

|

6

|

15

|

AC380V 30A

|

ESPA4040*10

|

4300*1000*2300

|

1700

|

|

RO-12000L/H

|

12

|

19

|

AC380V 35A

|

ESPA8040*12

|

8500*1600*1920

|

2500

|

|

RO-15000L/H

|

15

|

19

|

AC380V 35A

|

ESPA8040*15

|

10100*1870*3000

|

4000

|

|

RO-20000L/H

|

20

|

22.5

|

AC380V 45A

|

CPA28040*20

|

10000*1700*4200

|

4600

|

|

RO-30000L/H

|

30

|

37.5

|

AC380V 68A

|

CPA28040*25

|

13000*1900*3500

|

6000

|

|

RO-50000L/H

|

50

|

56

|

AC380V 120A

|

CPA28040*54

|

13500*2300*3800

|

9900

|

Recommend Products

Hot Searches