- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

≤0.01%

-

CrO Content (%):

-

≤0.01%

-

SiC Content (%):

-

≥85%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

JY-SC090601

-

Brand Name:

-

JINYU

-

Max use temperature:

-

1700 degree C

-

Density:

-

3.2g/cm3

-

Size:

-

Customized

-

Production line:

-

RBSIC, RSC, NSC, SSIC

-

OEM:

-

Accept

-

Sample order:

-

Accept

-

Shipping for sample:

-

By UPS, TNT, DHL, EMS, FEDEX etc.

Quick Details

-

SiO2 Content (%):

-

≤0.06%

-

Al2O3 Content (%):

-

≤0.02%

-

MgO Content (%):

-

≤0.02%

-

CaO Content (%):

-

≤0.01%

-

CrO Content (%):

-

≤0.01%

-

SiC Content (%):

-

≥85%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

JY-SC090601

-

Brand Name:

-

JINYU

-

Max use temperature:

-

1700 degree C

-

Density:

-

3.2g/cm3

-

Size:

-

Customized

-

Production line:

-

RBSIC, RSC, NSC, SSIC

-

OEM:

-

Accept

-

Sample order:

-

Accept

-

Shipping for sample:

-

By UPS, TNT, DHL, EMS, FEDEX etc.

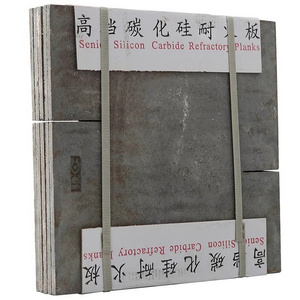

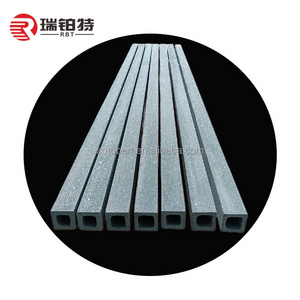

Furnace kiln using sintering refractory insulating silicon carbide sic brick

Furnace kiln using sintering refractory insulating silicon carbide sic brick are combined with high purity silicon carbide and ultra fines, shaped by vibration, made by high sintering. The SiC brick is an oxide bonded silicon carbide based product, which is used in Kiln Furniture. It is featured with high bending strength at elevated temperature, good abrasion resistance, Resistance to thermal shock, high thermal conductivity and offers a good life.

A. Characteristics of Furnace kiln using sintering refractory insulating silicon carbide sic brick :

- It has the characteristics of ware resistance, thermal shock resistance, high temperature structural and high resistivity to alkalis.

- Excellent thermal stability and distortion resistance at high temperature

- High mechanical strength at high temperature

- Excellent thermal shock resistance

- High thermal conductivity

- Excellent oxidating resistance

- Excellent corrosion resistance at high temperature

- Excellent corrosion resistance against chemicals

- High abrasion resistance

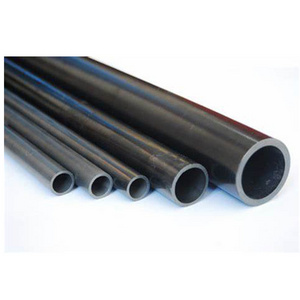

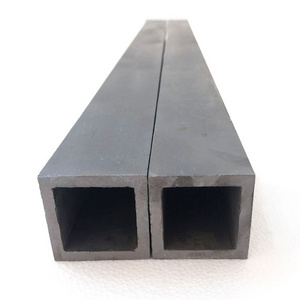

B. Production lines of Furnace kiln using sintering refractory insulating silicon carbide sic brick:

- Reaction Sintered Silicon carbide (RBSIC)

- Recrystallized Silicon Carbide ceramic (RSC)

- Nitride Bonded Silicon Carbide ceramic (NSC)

- Sintered Silicon Carbide (SSiC)

C. Typical Quality Analysis of Furnace kiln using sintering refractory insulating silicon carbide sic brick:

|

Item |

SIC-80 |

SIC-85 |

SIC-90 |

|

SiC, % min |

80 |

85 |

90 |

|

Bulk Density , g/cm3 |

2.60-2.70 |

2.60~2.70 |

2.70-2.75 |

|

Apparent Porosity , % max |

17 |

16 |

16 |

|

Cold Crushing strength, MPa min |

150 |

150 |

150 |

|

rupture strength under normal temperature, MPa min rupture strength at 1200 Cmin |

30 40 |

40 45 |

45 50 |

|

Thermal Conductivity, w/m.k min |

15 (1000C) |

16 |

18 (800C) 14 (1200C) |

|

thermal expansion coefficient, max |

4.7x10 -6 /C |

4.7x10 -6 /C |

4.7x10 -6 /C |

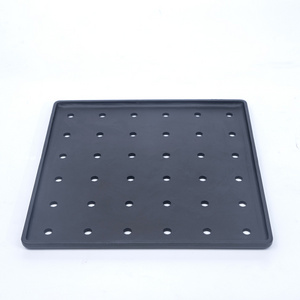

D. Specifications of Furnace kiln using sintering refractory insulating silicon carbide sic brick:

|

LxW |

LxW |

LxW |

LxW |

LxW |

|

765x730mm |

600x600mm |

550x380mm |

480x400mm |

400x400mm |

|

740x520mm |

600x550mm |

550x370mm |

480x360mm |

400x380mm |

|

732x445mm |

600x520mm |

550x300mm |

480x330mm |

400x350mm |

|

730x400mm |

600x500mm |

530x530mm |

460x440mm |

400x280mm |

|

730x280mm |

600x370mm |

530x340mm |

460x350mm |

400x250mm |

|

720x630mm |

560x380mm |

520x500mm |

460x320mm |

380x380mm |

|

700x700mm |

560x270mm |

520x490mm |

450x450mm |

365x365mm |

|

700x550mm |

550x550mm |

500x480mm |

450x420mm |

350x350mm |

|

700x500mm |

550x520mm |

500x450mm |

450x400mm |

340x320mm |

|

700x450mm |

550x500mm |

500x420mm |

450x380mm |

340x310mm |

|

640x600mm |

550x480mm |

500x400mm |

450x340mm |

320x320mm |

|

640x500mm |

550x450mm |

500x390mm |

430x420mm |

|

|

625x300mm |

550x430mm |

500x370mm |

420x400mm |

|

|

610x400mm |

550x400mm |

480x480mm |

420x380mm |

|

|

Thickness 8-25mm |

Other specifications are available |

|||

Plastic paper inside, Polyfoam filled, Wooden box outside.

--By DHL/Fedex (Door to door, Home delivery service)

--By Air to your nearest Airport

--By Sea to your nearest Seaport

--By the sellers’ shipping agent

As a professional exporter, our target is to serve worldwide clients with high-quality products, great reliability,

devoted responsibility, professional services and honorable credibility to meet customers' requirements in all

aspects. Offering skillful after-sale service, specialists are available for all customers at 7*24 hours every week.

As for payment, except for (L/C, TT etc), our company also accepts all kinds of emerging payment terms

(like Western Union, MoneyGram etc) to provide convenience for you.

If you have any questions, please do not hesitate to contact us!

Ways to order Silicon Carbide:

Email us now with your specific requirements and they will reply you to discuss the details of your order and answer

any questions you may have about your requirements, or the services we can provide to help you and your business.

Call us now and one of our specialists will help you make your order as well as discuss any other requirements you

may have.

Click “ send” now and the services will help you make your order as well as discuss any other requirements you may

have.