- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

100

-

Product name:

-

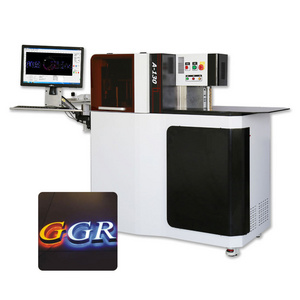

M200

-

Processing material:

-

Flat Metal

-

Material thickness:

-

0.6 -1.2 mm

-

Max. Processed Width:

-

30mm -200mm

-

Voltage:

-

220V 50HZ

-

Power:

-

3KW

-

Function:

-

Auto Feeding+bending+slotting

-

Supporting software:

-

CorelDRAW / AI

-

Packing:

-

Wooden Box

-

Process file format:

-

DXF / AI / PLT

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Drive CNC

-

Year:

-

2023

-

Weight (KG):

-

100

-

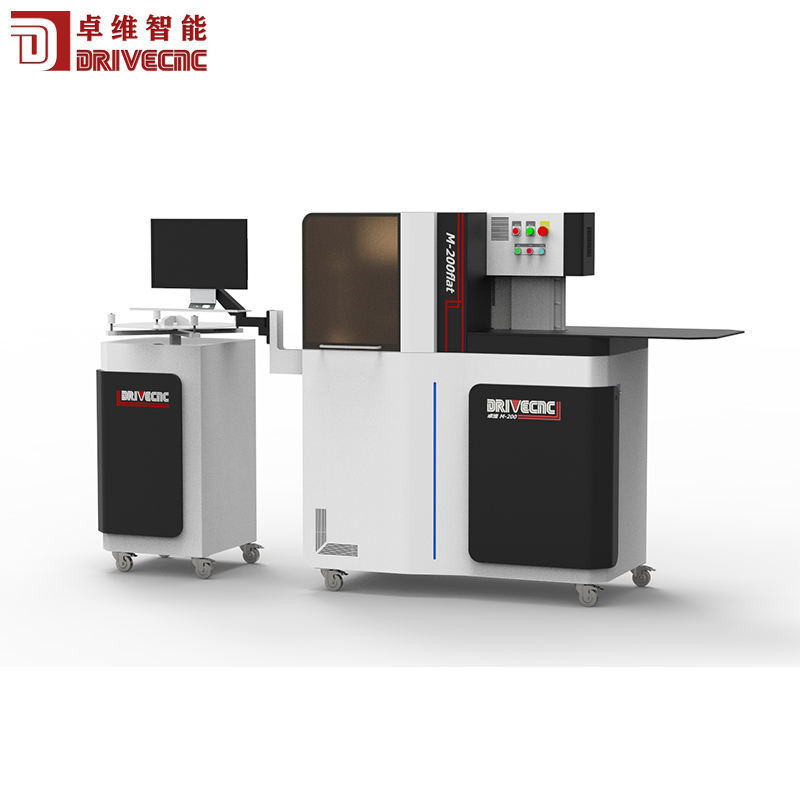

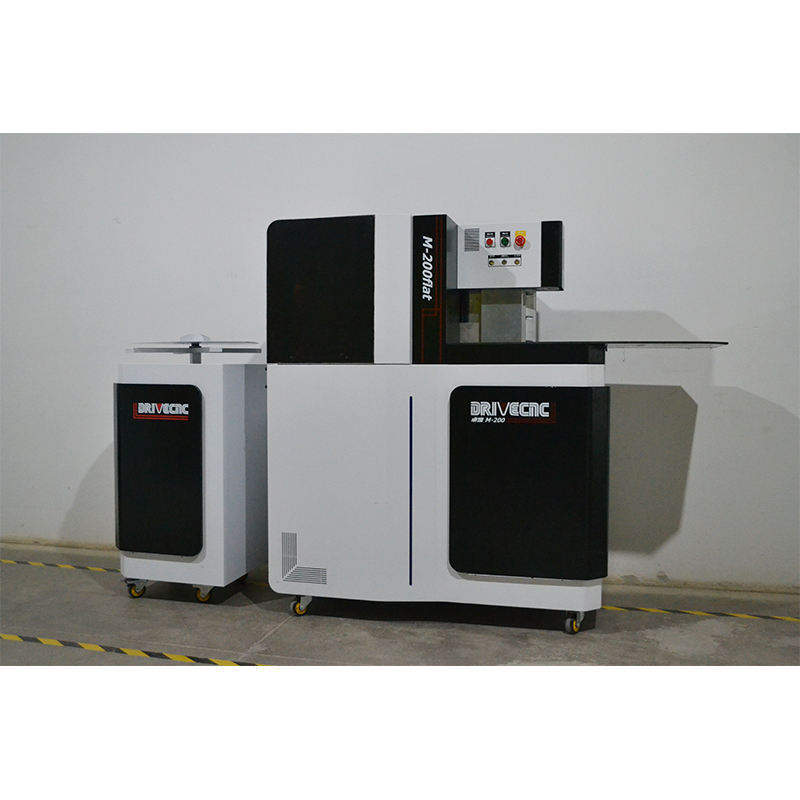

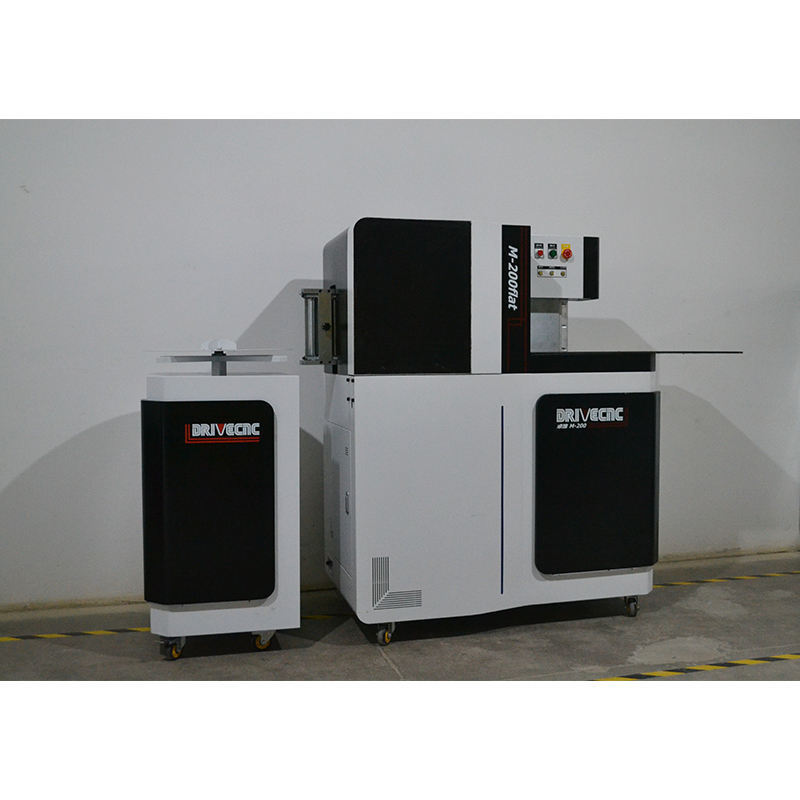

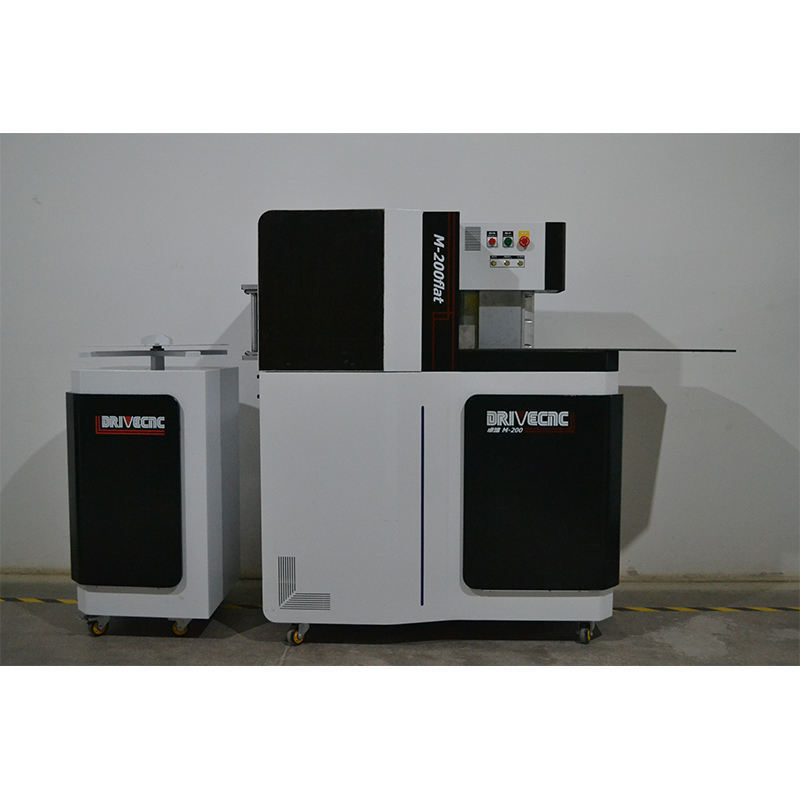

Product name:

-

M200

-

Processing material:

-

Flat Metal

-

Material thickness:

-

0.6 -1.2 mm

-

Max. Processed Width:

-

30mm -200mm

-

Voltage:

-

220V 50HZ

-

Power:

-

3KW

-

Function:

-

Auto Feeding+bending+slotting

-

Supporting software:

-

CorelDRAW / AI

-

Packing:

-

Wooden Box

-

Process file format:

-

DXF / AI / PLT

Product Description

Specification

|

|

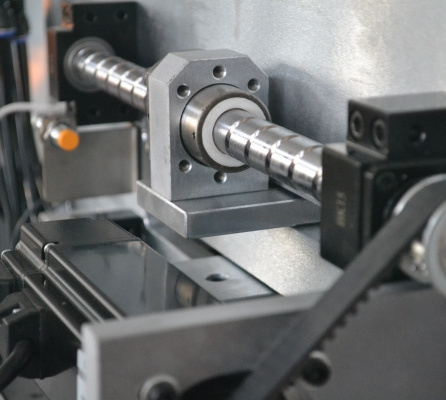

Feeding system

|

Precision screw transmission and mechanical arm alternatively feeding structure (closed loop self-test system)

|

|

|

|

|

Slotting system

|

Hard alloy planer

|

|

|

|

|

Bending system

|

Double -pole alternate part-arc institution and patented alternative arc-extrusion structure

|

|

|

|

|

Driving motor

|

Servo motor 3 set, stepper motor 1 set

|

|

|

|

|

Equipment weight

|

480 KG

|

|

|

|

|

Dimensions

|

Body L2300*W700*H1570mm / Feeding table L500*W500*H1200mm

|

|

|

|

|

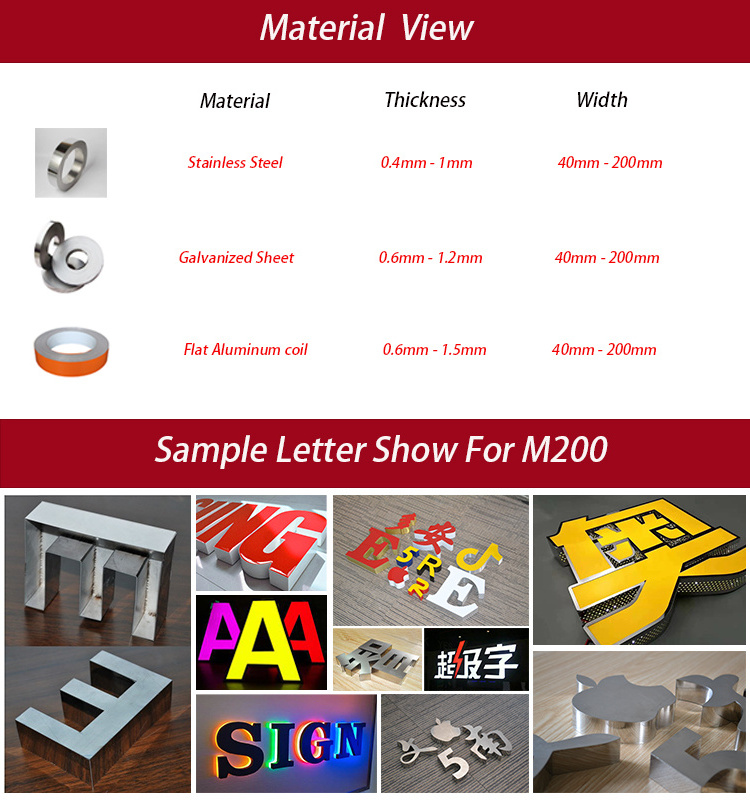

Material category

|

Flat aluminum /Stainless steel / Galvanized plate (height: 20-200mm)

|

|

|

|

|

Material thickness

|

Flat aluminum :0.6 - 1.5 mm/ SS :0.3-1.2mm / Galvanized sheet:0.4-1.2mm

|

|

|

|

|

Support format

|

AI / PLT / DXF

|

|

|

|

|

Feeding accuracy

|

Length + 0.1mm Radius > 4mm

|

|

|

|

|

Control card

|

Leetro Four -axis motion control card

|

|

|

|

|

Software system

|

Auto drive / CBS4 auto bending system

|

|

|

|

|

Input voltage

|

220V 50Hz 3KW

|

|

|

|

|

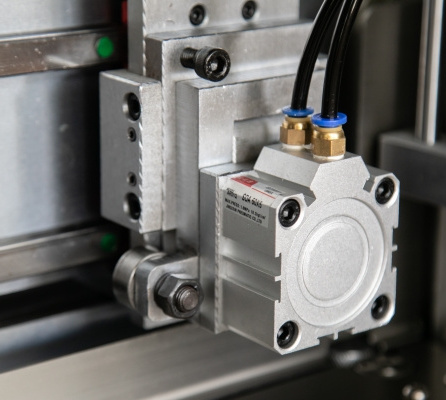

Air pressure

|

0.6-0.8Mpa

|

|

|

Details Images

Feeding structure

Mechanical Arm

material reminding structure

Connect material reminding structure

When the material is not enough longer,the structure will work, and machine software will show prompt message and stop feed material. when the user connect new material for processing , machine can resume normal work.

Slotting structure

Circular progressive slotting structure

The slotting structure can make sure that the

depth of groove is same all the time when machine working ,it is good for welding letter when the user need to make SS strip with Metal board together. the processed material will not be broken easily.

Planer tool

Ball screw

Bending structure

Servo motor and drive

Machine software

Advanced bending software,

it is more suitable for user. Easy to operate.

it is user friendly . easy to change paramters follow different material .

Packing & Delivery

Installation Instructions

https://youtu.be/aZUhb9ANAzg

The video will show you how to install machine parts when you get it.

https://youtu.be/M16Ygy5RMfM

The video will show you how to install machine software drive and operate the software.

https://youtu.be/3Y2A8catDas

Recommend Products

Hot Searches