- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Walker

-

Product name:

-

Cone crusher mantle

-

Color:

-

Customer's Requirement

-

MOQ:

-

1 Set

-

Advantage:

-

Wear Resistant

-

Standard:

-

International

-

Packing:

-

Standared Package

-

Quality:

-

High Level

-

Delivery time:

-

7-15 Days

-

After-sales Service:

-

Provided

-

Feature:

-

Competitve

Quick Details

-

Weight (KG):

-

200

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Walker

-

Product name:

-

Cone crusher mantle

-

Color:

-

Customer's Requirement

-

MOQ:

-

1 Set

-

Advantage:

-

Wear Resistant

-

Standard:

-

International

-

Packing:

-

Standared Package

-

Quality:

-

High Level

-

Delivery time:

-

7-15 Days

-

After-sales Service:

-

Provided

-

Feature:

-

Competitve

Product Description

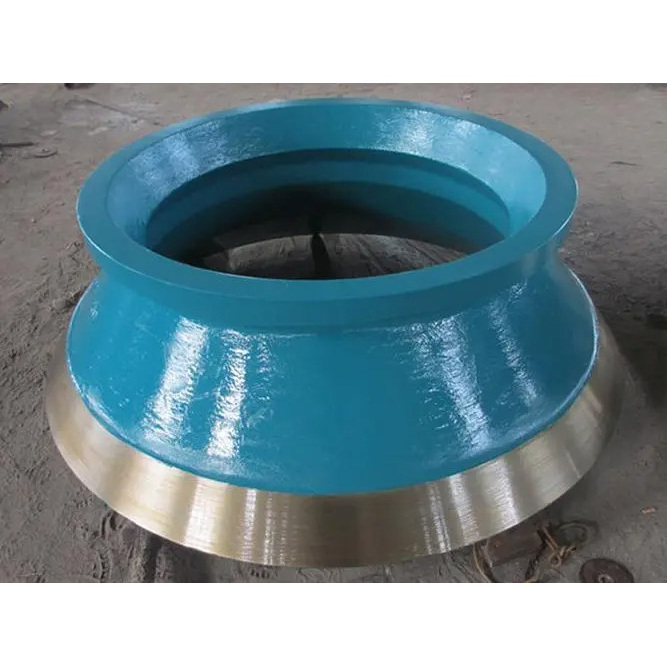

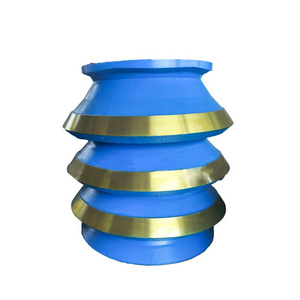

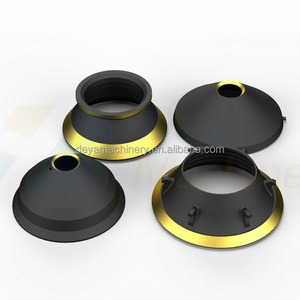

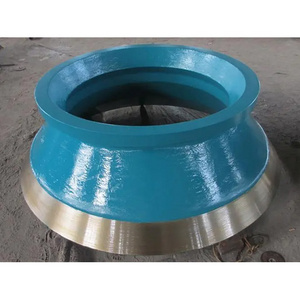

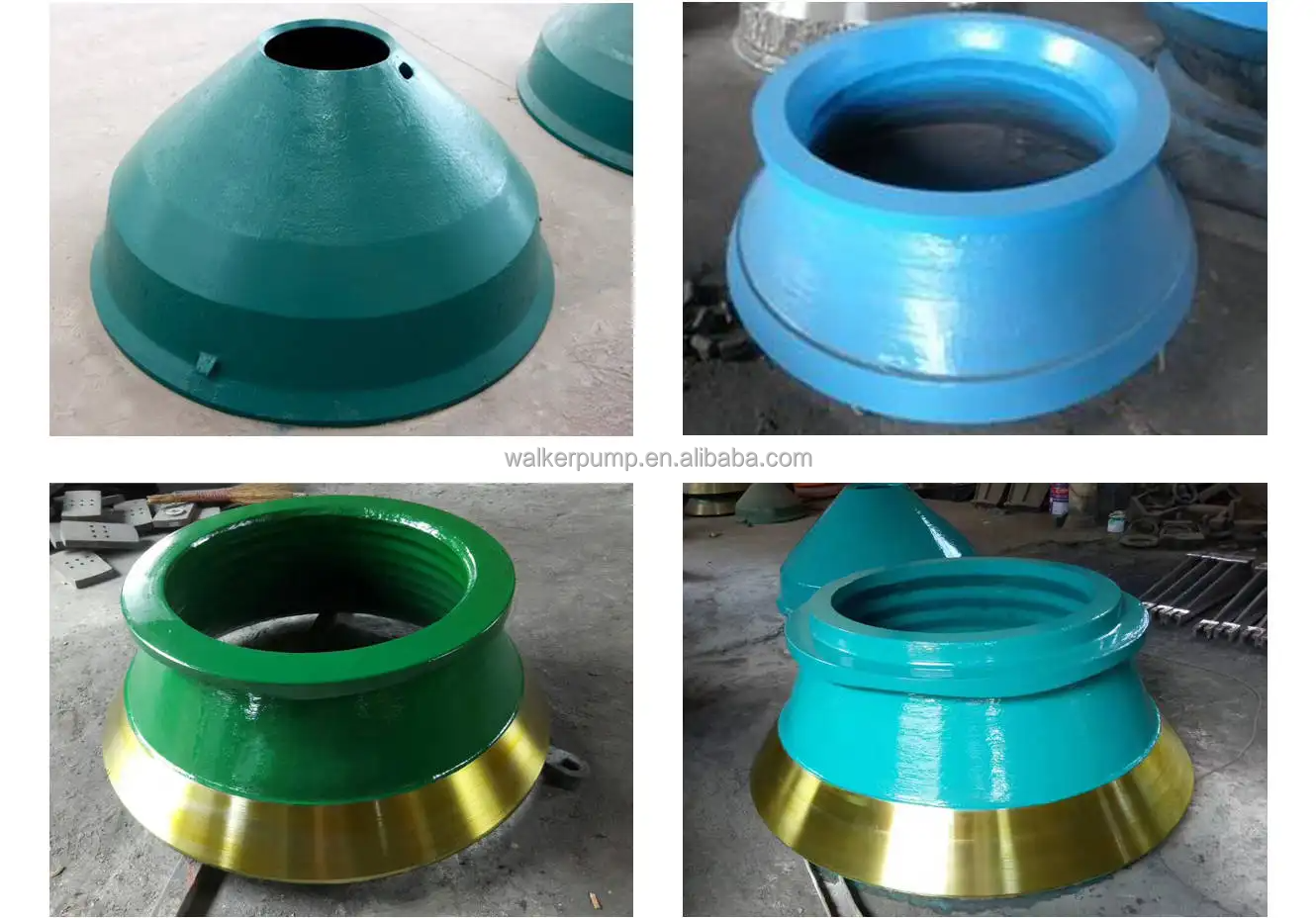

MANTLE | BOWL LINER

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl liner.

The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

WALKER cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

Why choose us

Our massive database and mold inventory ensures that you can get any crushing cavities of most popular cone crushers, and guarantee 100% avaliability.

Our strong casting and machining capability with strict production schedule arrangement, make sure your order trackable in any steps. Deliver the goods without any delay than the expect lead time.

Specification:

We are holding a vast mold inventory for a wide crusher seires. The mantles and concaves range we can supply include but are not limited to those models listed below.

|

Metso

|

|

|

|

|

|

|

||||||

|

Nordberg Symons

|

Nordberg Omnicone

|

Nordberg HP Series

|

Nordberg GP Series

|

Nordberg MP Series

|

Metso MX Series

|

Lokotrack LT Series

|

||||||

|

2'

3' 4' 4¼' 4800 5½' 5100 7' |

1144

1352 1560 937 |

HP100

HP200 HP3 HP300 HP4 HP400 HP5 HP500 HP6 HP900 |

GP100

GP100S GP220 GP200S GP330 GP300S GP550 GP500S GP7 |

MP800

MP1000 MP1250 MP2500 |

MX3

MX4 |

LT200HPS

LT200HP LT300HP LT300GP LT220D LT330D |

||||||

|

Terex

|

|

|

|

|||

|

Terex Powerscreen

|

Terex Finlay

|

Terex Cedarapids

|

Terex Cedarapids

|

|||

|

1000 Maxtrak

1000SR 1150 Maxtrak 1300 Maxtrak 1500 Maxtrak |

C-1554

C-1550 C-1550P C-1545 C-1545P C-1540 C-1540P C-1540RS |

TC1000

TC1150 TC1300 TG120 TG220 TG320 TG420 TG820 TG1020 |

TGS120

TGS220 TGS320 TGS420 MVP380X MVP450X MVP550X |

|||

|

Sandvik

|

|

|

||

|

Sandvik CH Series

|

Sandvik CS Series

|

Sandvik QH Series

|

||

|

CH420

CH430 CH440 CH660 CH830i CH840i CH860i CH865i CH870i CH890i CH895i |

CS420

CS430 CS440 CS660 CS840i |

QH441

QH332 QS332 UH640 US440E US440i UH440i UH440E |

||

|

Others

|

|

|

|

|||

|

Flsmidth Raptor Series

|

Telsmith Titan Series

|

Telsmith SBS & SBX Series

|

McCloskey C Series

|

|||

|

Raptor 200

Raptor 300 Raptor 400 Raptor 500 Raptor 600 Raptor 900 Raptor 1000 Raptor 1100 Raptor 1300 Raptor 2000 |

T200

T300 T400 T500 |

38 SBS

44 SBS 52 SBS 57 SBS 68 SBS 44 SBX 52 SBX 57 SBX |

C2

C2R C3 C3R C4 |

|||

High Manganese Steel Cone Crusher Mantle & Bowl Liner

We offer cone crusher mantles and bowl liners in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%.

*NOTE: All manufacturer names, part numbers, model numbers and descriptions are used for reference and identification purposes only, they are owned by the respective machine manufacturer. All parts supplied are manufactured and warranted by WALKER and are not manufactured by or purchased from the Original Equipment Manufacturer. WALKER has no association with the OEM and do not intend to give this impression.

Packing & Delivery

◆ Ways of packing

1.Small parts packed in the wooden cases

2.Big parts packed by plastic membrane

3.The whole big machine is loaded in the container

3.The whole big machine is loaded in the container

◆ Shiping by sea/air freight

1. Usually our mining machines are shipped in 40'HQ or Flat Containers by sea.

2. Our mining equipments can be also shipped by air if customers request.

2. Our mining equipments can be also shipped by air if customers request.

Company Introduction

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our core advantages as below:

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

●

Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches