- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Dry grain,wheat,rice,Corn

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TIANZE

-

Name:

-

Rice Drying Machine

-

Capacity:

-

1t/batch

-

Drying time:

-

2-3h/batch

-

Body:

-

Carbon steel

-

Application:

-

Dry grain,rice,wheat,etc

-

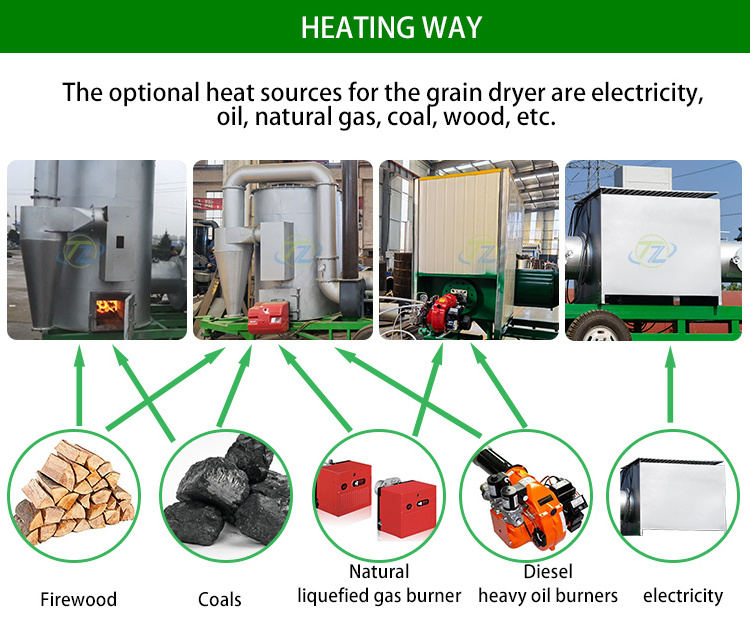

Fuel:

-

Coal,Wood,Diesel,Gas

-

Silo volume:

-

6.5CBM

-

Fan power:

-

4kw

-

Delivery:

-

20 gp container

Quick Details

-

Weight (KG):

-

3000

-

Marketing Type:

-

New Product

-

Type:

-

Mobile dryer

-

Use:

-

Dry grain,wheat,rice,Corn

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TIANZE

-

Name:

-

Rice Drying Machine

-

Capacity:

-

1t/batch

-

Drying time:

-

2-3h/batch

-

Body:

-

Carbon steel

-

Application:

-

Dry grain,rice,wheat,etc

-

Fuel:

-

Coal,Wood,Diesel,Gas

-

Silo volume:

-

6.5CBM

-

Fan power:

-

4kw

-

Delivery:

-

20 gp container

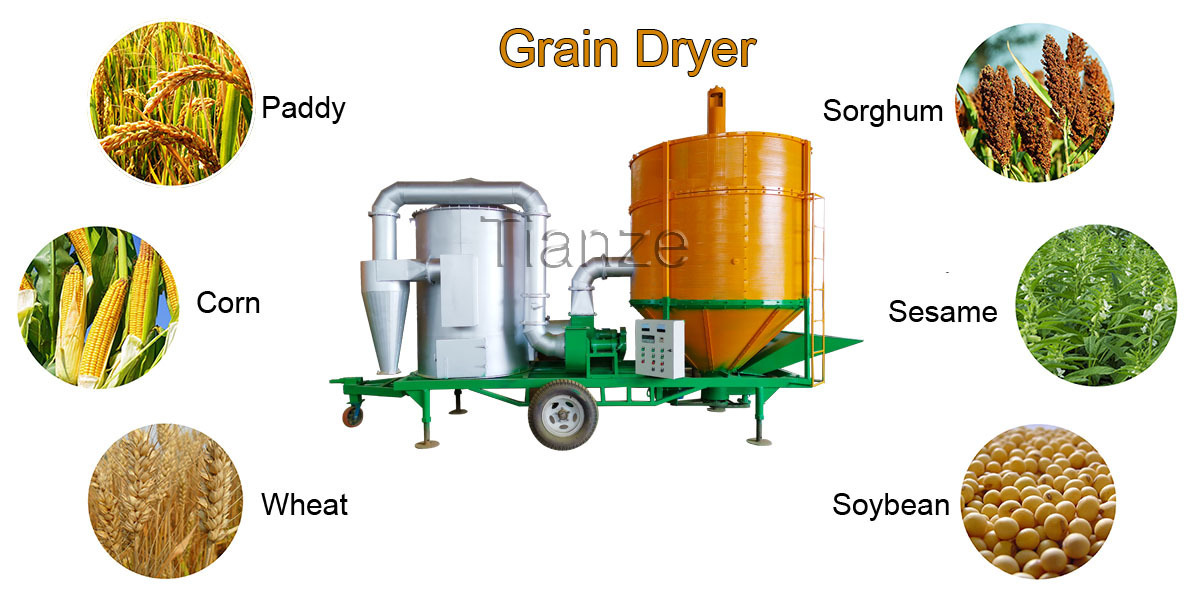

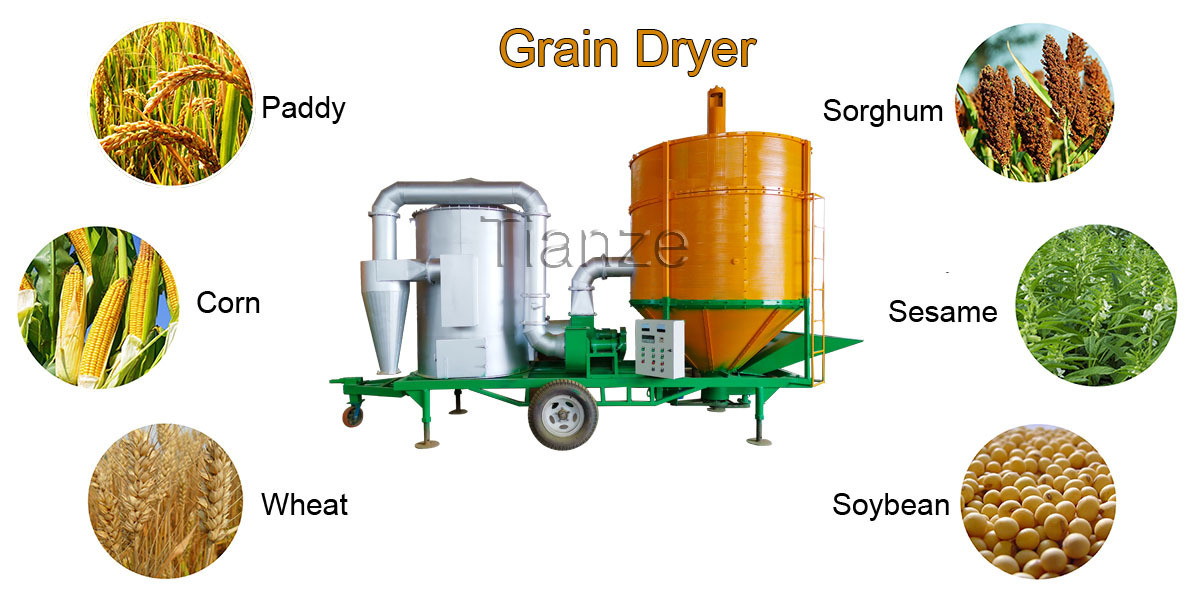

Small Mobile Raw Paddy Dryer Parboiled Rice Drying Machine

Today cereal drying technology is as important as cereal storage. Tianze do our best to meet customer’s requirement and supply high efficiency and quality grain dryer.It is w idely use for corn, paddy, wheat, sesame,bean,and other particle material,etc.

Applications

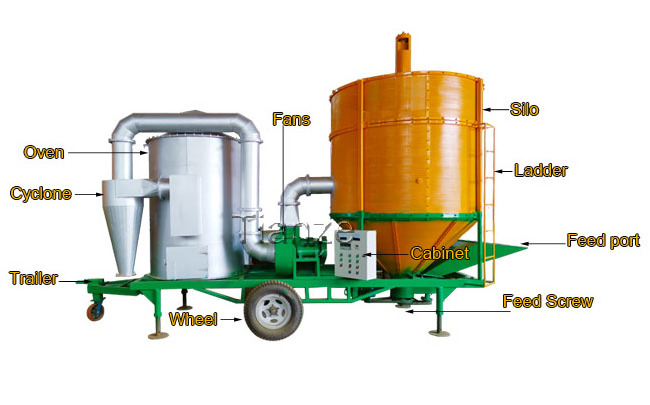

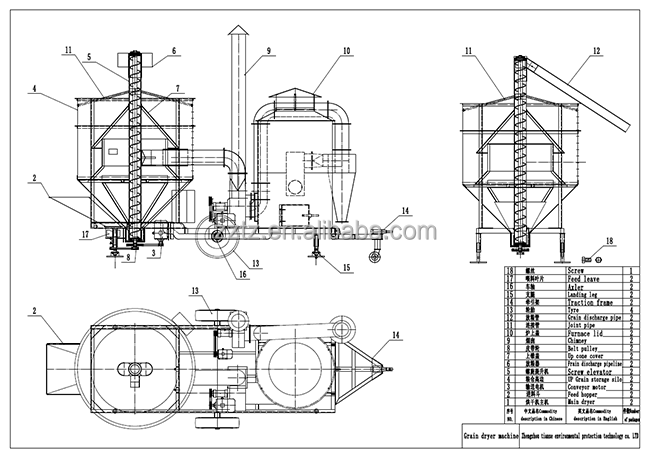

Dryer structure

Advantage of Small Mobile Raw Paddy Dryer Parboiled Rice Drying Machine

1.Adopt advance technology from Europe:With Short drying time, keep cereal feature with suitable temperature, reduce drying cost.

2.Body compact, easy operation, especially design for small and middle farmer and company

3.High drying efficiency, easy transport, save space, it can be moved to farm and drying everywhere.

4.Widely use for corn, paddy, wheat, sesame, etc.

Features of Small Mobile Raw Paddy Dryer Parboiled Rice Drying Machine

1.Mobile,it with mobile wheel and device, can be towed by tractor.

2.Cereal without pollution, fresh air as input and make sure cereal clean without pollution.

3.Automatic control system for temperature and moisture.

4.Display on time

5.Machine can be separate and install together, easy transport

Technical Parameters

|

Model |

TZ-1D |

TZ-2D

|

TZ-4D |

TZ-6D |

||

|

Silo Volume |

1.5m³ |

3.8m³ |

6.5m³ |

9.6m³ |

||

|

Dry type |

Low temperature hot air cycle dry | |||||

|

A ir temperature range |

Paddy:45-60℃;Corn:100-130℃;Wheat:90-110℃ |

|||||

|

Transport height |

2.1m |

2.7m |

2.9m |

2.9m |

||

|

Operation height |

2.1m |

3.46m |

3.85m |

4.92m |

||

|

Area |

8m2 |

13m2 |

15.5m2 |

16.3m2 |

||

|

Coal and wood Oven |

Clean oven, Ignition by manual (If use other fuel,need different design) |

|||||

|

Fuel consumption |

Coal |

(Standard conditions)18kg/t |

||||

|

Gas |

(Standard conditions)7m³/t |

|||||

|

Diesel oil |

(Standard conditions)7.5L/t |

|||||

|

Total power |

3kw |

8.5kw |

13.13kw |

19.4kw |

||

|

Capacity :

|

1T/batch |

2T/batchh |

4T/batch |

6T/batch |

||

|

Note:Each batch need 2-3h |

||||||

|

Precipitation rate (%/h) |

Paddy:1.7-2.5℃;Corn:3.8-6;Wheat:2.8-4.5℃ |

|||||

|

Safety Devices |

Thermal relay,Error alarm, Times Switch, Overheat alam |

|||||

|

Daily production is calculated by the condition from25% to 14% moisture. |

||||||

More Images

Machine material and color

support customization

Detailed Images

Customer Site

Other related machine

Packaging & Shipping

Grain dryer machine packing and delivery

(1) Simple packaging.Other in wooden boxes;

(2) Delivery the machine by 20-foot container/40-foot container;

(3) Delivery the machine within 7 days after receiving balance payment

About Us

Service before sale:

1.24 hours online to answer questions that you want to know about the grain dryer machine(Wechat ,Whatsapp ,QQ , Trade Manager ),or you can putthe questions all you want to know about the grain dryer and sent to my mailbox, I will give you a satisfactory answer.

2.My company is specialized in producing grain dryer machine, my edible grain dryer machine is very advanced in the international, My company may transform grain dryer according to customer requirements, we can also accept customer design drawings to manufacture grain dryer machine.

After-sales services: We offer one year warranty for the whole machine except easy broken parts, Providing the spare parts with favorable price all the time 24 hours online service.

FAQ

Q: How about the quality of your products?

A:We put the quality in the first place based on the honesty. Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before the delivery. You can also use Trade Assurance by Alibaba for product quality protection, punctual shipment protection and payment protection.

Q: How about the price?

A: We pursue small profits but quick turnover, and we can give you lower price than other trading companies. Besides, customers from Alibaba can get a discount. If the product is really suitable and can benefit you, the price is negotiable.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Can you help chose suitable products?

A: Yes. We have many experts who have worked in this field for many years. They can help you select the most suitable products according to your actual condition. And they can design proper process flow based on your special situation. If necessary, we can even send professionals to your local place for site planning and work-flow design.

Why Choose Us

Zhengzhou Tianze Environmental Protection Technology Co., Ltd. Founded in 2010, and has 6 technical R & D personnel, annual sales of more than 5000 sets of machinery, is one of the earliest production of grain dryer machine in China. Advanced and reasonable design, easy operation and maintenance.

Each technology, quality indicators are in line with industry standard. Currently, we have product agents and after-sales service providers in many countries and regions of the world!

The company has passed the ISO9001: 2000 quality management system certification and has a number of invention patents.

Zhengzhou Tianze Environmental Protection Technology Co., Ltd. regards quality as life, adheres to integrity, mutual benefit and common prosperity, and carries things with virtue; in accordance with the current high-standard production process, to ensure product quality and service quality.

Welcome global users to discuss cooperation.