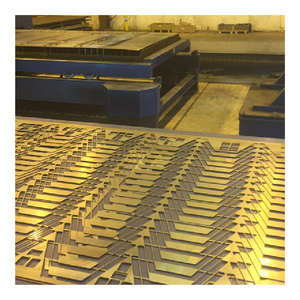

Custom Cnc Machining Laser Cutting Parts 6061 5052 Aluminum Bending and Forming Rivets Sheet Metal Service

-

Transport Package:

-

Customized safaty package

-

Specification:

-

Custoized according to design drawings

-

Trademark:

-

Provide 3D step/stl/pdf design drawing for quote by email inquiry@protoindustry.com

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

Shenzhen of China

-

Application:

-

Fastener Auto and Motorcycle Accessory Hardware Tool Machinery Accessory Other household application, auto, electronic, medical agriculture

-

Standard:

-

GB EN API650 China GB Code JIS Code TEMA ASME Other Custoized according to design drawings According to customer's requirements

-

Surface Treatment:

-

Powder Coated Passivating Anodizing Spray Paint Electroplating Brushed Sand Blasted Polishing Other Polishing,Anodizing,Brushed,Sand Blasted ects According to customer's requirements

-

Production Type:

-

Mass Production Batch Production Single Production Single Production,Batch Production and Mass Produc According to customer's requirements

-

Machining Method:

-

Broaching Extrusion CNC Stamping CNC Milling CNC Turning CNC Machining CNC Machining Milling Turning Broaching According to customer's requirements

-

Material:

-

Nylon Steel Plastic Brass Alloy Copper Aluminum Iron Aluminum Steel According to customer's requirements

-

Payment:

-

L/C T/T D/P Western Union Paypal Money Gram

-

Export Port:

-

SHENZHEN PORT

-

Output:

-

100000PIECE/MONTH

-

Model NO:

-

WhatsApp quote +86 13480927180

Quick Details

For any new inquirys,please send us 3D stp/igs/stl format design files,and tell us the part material,quantity and surface finish requirements for quotation as follow:

We provide CNC machining services of any complexity for the production of both small and large series of parts. Our online Instant Quoting Engine gives you a CNC machining quote within seconds. Then, we make your machined metal or plastic parts and get them to your door in up to 3-5days. We inspect the parts and guarantee their quality. Requesting a quotation for CNC machining is easy: just upload your files with drawings, 3D-models or sketches in any popular formats to

CNC Machining Cutting Milling Service

CNC Turning Lathing Service

Advantages of Ordering CNC Machined Parts from Proto Industry Manufatcory

Material Selection

Choose from over 30 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

Aluminum alloy selection EN AW-2007 / 3.1645 / AlCuMgPb EN AW-6060 / 3.3206 / Al-MgSi EN AW-6061 / 3.3211 / Al-Mg1SiCu EN AW-6082 / 3.2315 / Al-Si1Mg EN AW-5083 / 3.3547 / Al-Mg4,5Mn EN AW-7075 / 3.4365 / Al-Zn6MgCu

Custom aluminium alloys are also available

Steel alloy selection 1.0038 / St37-K / S235JR 1.0503 / C45 1.0570 / St52-3 / S355J2G3 Custom steel alloys are also available Stainless Steel: 1.4301 / X5CrNi18.10(V2A) 1.4404 / X2CrNiMo17-12-2 (V4A) 1.4571 / X6CrNiMoTi17-12-2 1.7131 / 16MnCr5 1.7225 / 42CrMo4 Custom stainless steel alloys are also available

Copper or brass alloy selection 2.0060 / E-Cu57 / Cu-ETP / CW004A 2.0065 / E-Cu58 / CW004A Ms58 / 2.0401 / CuZn39Pb3 Custom copper and brass alloys are also available

Titanium material selection Grade 2 / EN 3.7035 Grade 5 / 6AL-4V9

Polymers ABS Acrylic Acetal / Delrin / POM Nylon / Polycaprolactam PC / Polycarbonate PEEK / Polyether ether ketone PEEK Glass-Filled PP Polypropylene PTFE / Teflon PVD F UHMW PE / Ultra-high-molecular-weight polyethylene Custom polymers are also available

Rapid Turnaround

Using the latest CNC machines, Proto produces highly accurate, quick turn parts in as fast as 3-5 days.

Custom Finishes

Select from a variety of finishes on solid metal and plastic parts, built to precise design specifications.

Bead blasting Anodising,Powder coating Electropolishing Passivation, Electroless nickel plating Gold plating Zinc coating / Galvanising Black oxide Annealing Case-hardening (Carburising) Tempering Through hardening ects

Precision

Proto Industry Manufactory offers various tolerance options in accordance with ISO 2768 (Standard, Fine) and ISO 286 (Grades 8, 7, 6)

Quality Control

Proto Industry Manufactory QA department performs strong quality assurance.

Fast Delivery

Proto Industry Manufactory delivers parts to many countries fastly. Just get a quote and see available delivery options along with your parts quote.

FAQ

1.What's MOQ request?

MOQ 1PCS SAMPLE ACCEPTALE

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 3-5 days for prototype sample.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension. (2)Production first inspection--To ensure the critical dimension in mass production. (3)Sampling inspection--Check the quality before sending to the warehouse. (4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.