- Product Details

- {{item.text}}

Quick Details

-

Feed Mechanism:

-

Automatic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Good Time

-

Power:

-

750W

-

Overall Dimensions:

-

125x65x125cm

-

Weight (KG):

-

150 KG

-

Keywords:

-

leather shoes skiving machine

-

Application:

-

handbag skiving machine

-

Usage:

-

men and women leather shoes

-

Product name:

-

computer direct drive leather skiving machine

-

Function:

-

peeling/skiving and trimming of all kinds of leather

-

Feature:

-

computer direct drive

-

Speed:

-

can be adjustable

-

Key words:

-

Leather Peeling Machine

-

Suitable for:

-

cutting the edge and surface of shoes, belt, bag

-

Characteristics:

-

With vacuum cleaner

-

Certification:

-

CE

-

Marketing Type:

-

Hot sale 2021

Quick Details

-

Type:

-

Industrial Sewing Machine

-

Max. Sewing Thickness:

-

5mm

-

Stitch Length:

-

0.1-12.7m

-

Feed Mechanism:

-

Automatic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Good Time

-

Power:

-

750W

-

Overall Dimensions:

-

125x65x125cm

-

Weight (KG):

-

150 KG

-

Keywords:

-

leather shoes skiving machine

-

Application:

-

handbag skiving machine

-

Usage:

-

men and women leather shoes

-

Product name:

-

computer direct drive leather skiving machine

-

Function:

-

peeling/skiving and trimming of all kinds of leather

-

Feature:

-

computer direct drive

-

Speed:

-

can be adjustable

-

Key words:

-

Leather Peeling Machine

-

Suitable for:

-

cutting the edge and surface of shoes, belt, bag

-

Characteristics:

-

With vacuum cleaner

-

Certification:

-

CE

-

Marketing Type:

-

Hot sale 2021

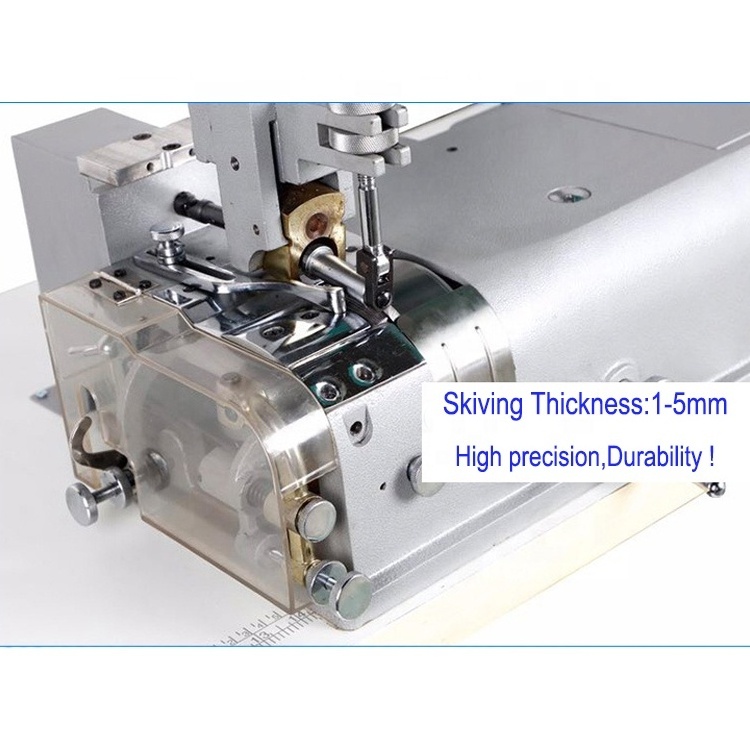

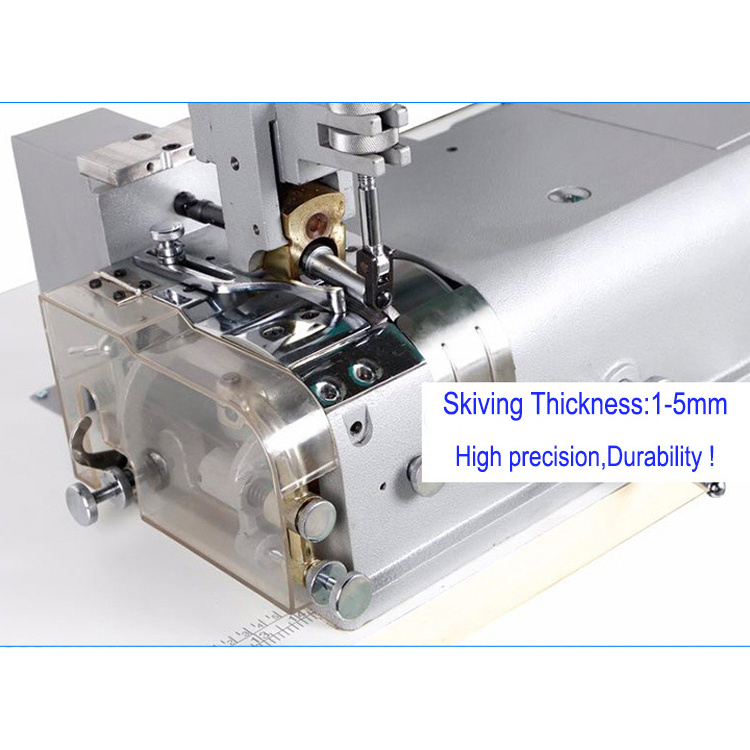

Double computer direct drive leather skiving machine with circular knife industrial skiving machine.

1. Double direct drive, double speed regulation, computer control, new concept of double direct drive leather skiving machine.

2. The feeding structure adopts the direct drive structure, the feeding speed can be adjusted, 80-500 rpm/min, and the suitable feeding speed can be selected for various materials. Ensure smooth cutting & skiving.

3. The circular cutter adopts servo motor and direct drive, so as to reduce transmission loss and improve work efficiency. The cutting speed of the circular cutter can be adjusted freely, 0-3200 rpm/min, so as to maximize the cutting efficiency.

4. Plan cutting & skiving, the thinnest can reach 0.05mm, thinner than the paper. The thickest for leather, can be reach 2.5mm-3mm. Round knife, cutting & skiving width, up to 50mm.

5. The computer control panel has clear display and easy operation, and can freely switch the pedal mode or the automatic mode.

6. The biggest advantages of double direct drive, double speed regulation and double control can ensure that users can choose the appropriate cutting speed and feeding speed according to different cutting materials. The real realization of mechatronics, with the computer to control the speed, to ensure the product quality requirements.

7. The design of feeding direct drive device is more simple and efficient, which greatly reduces the maintenance confusion of the original peeler through the gearbox transmission, greatly reduces the failure rate of the machine, and greatly improves the work efficiency.

|

Model: |

GT-801D2 |

|

Motor: |

750W |

|

Voltage : |

220V, 50-60Hz / 110V,50-60Hz for optional |

|

Skiving thickness: |

0.05mm-3mm |

|

Working speed: |

0-3200rpm/min |

|

Skiving width: |

10-50 mm |

|

Voice: |

<60db |

|

Demension: |

125X65X125cm |

|

Weight: |

95kgs |

Double direct drive, double speed regulation, computer control, new concept of double direct drive leather skiving machine.

The feeding structure adopts the direct drive structure, the feeding speed can be adjusted, 80-500 rpm/min, and the suitable feeding speed can be selected for various materials. Ensure smooth cutting & skiving.

The circular cutter adopts servo motor and direct drive, so as to reduce transmission loss and improve work efficiency. The cutting speed of the circular cutter can be adjusted freely, 0-3200 rpm/min, so as to maximize the cutting efficiency.

Plan cutting & skiving, the thinnest can reach 0.05mm, thinner than the paper. The thickest for leather, can be reach 2.5mm-3mm. Round knife, cutting & skiving width, up to 50mm.

The computer control panel has clear display and easy operation, and can freely switch the pedal mode or the automatic mode.

With automatic vacuum cleaner, clean, environmental protection.

The biggest advantages of double direct drive, double speed regulation and double control can ensure that users can choose the appropriate cutting speed and feeding speed according to different cutting materials. The real realization of mechatronics, with the computer to control the speed, to ensure the product quality requirements.

The design of feeding direct drive device is more simple and efficient, which greatly reduces the maintenance confusion of the original peeler through the gearbox transmission, greatly reduces the failure rate of the machine, and greatly improves the work efficiency.

It is suitable for peeling/skiving and trimming of all kinds of leather products. Widely used in leather shoes, leather clothes, handbags, belts, gloves and other natural leather, PU leather folding, edge groove, and uniform thinning processing.