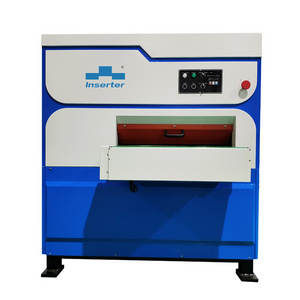

GOOD SHAPE

SAFETY FRAME

SIMPLE CONTROL

SEASY MAINTENANCE

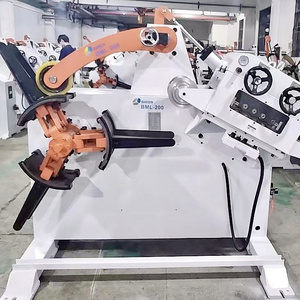

VERSATILITY

IMPROVE THE ANISOTROPY OF MATERIALS