- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

100 KG

-

Power:

-

130kw

-

Name:

-

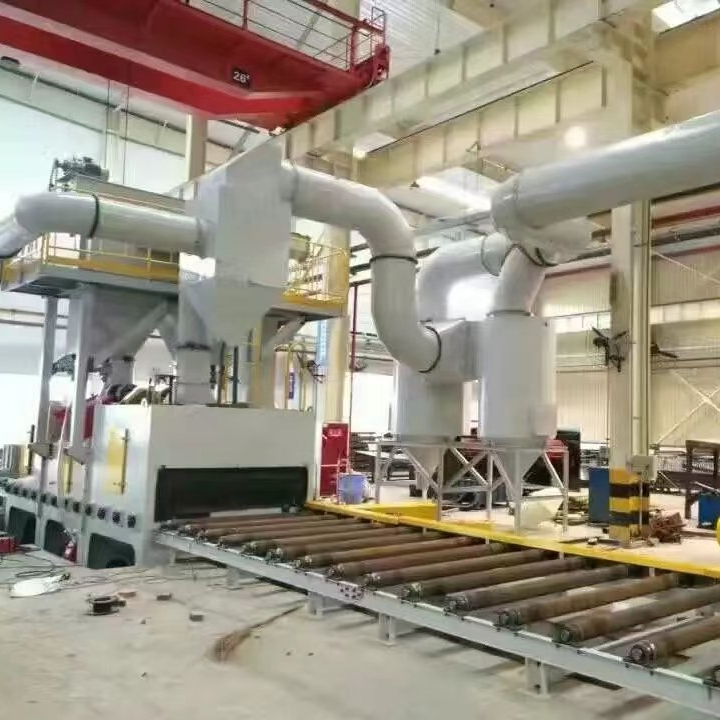

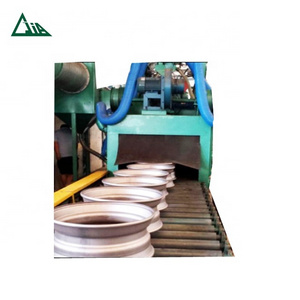

Shot Blast Cleaning Machine

-

Application:

-

Surface Cleaning

-

Product name:

-

Steel Shot Blasting

-

Type:

-

Shot Blasting Machine Equipment

-

Function:

-

Metal Rust Surface Cleaning

-

Blasting media:

-

Steel Balls

-

Keywords:

-

Shot Blast Cleaning Equipment

-

Color:

-

Blue

-

Shot blast machine type:

-

Through shot blasting machine

-

Abrator:

-

High Performance Shot Blasting Blade

Quick Details

-

Place of Origin:

-

jiangsu

-

Brand Name:

-

delogn

-

Core Components:

-

Body of the shot blasting chamber

-

Weight (KG):

-

100 KG

-

Power:

-

130kw

-

Name:

-

Shot Blast Cleaning Machine

-

Application:

-

Surface Cleaning

-

Product name:

-

Steel Shot Blasting

-

Type:

-

Shot Blasting Machine Equipment

-

Function:

-

Metal Rust Surface Cleaning

-

Blasting media:

-

Steel Balls

-

Keywords:

-

Shot Blast Cleaning Equipment

-

Color:

-

Blue

-

Shot blast machine type:

-

Through shot blasting machine

-

Abrator:

-

High Performance Shot Blasting Blade

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Advantage:

1) High uniformity of physical properties

The use of advanced cutting and grinding technology to ensure that the size, hardness and density of all balls are highly unified, and the unity of these factors greatly improves the shot peening strength. The accuracy of saturation curve improves the efficiency of shot peening.

2) Longer service life greatly saves production costs

The special treatment process of strengthened steel balls ensures the unity of the internal molecular structure of the balls, thus greatly improving the service life of the balls, which not only reduces the consumption of customers, but also saves a lot of costs for customers in equipment maintenance and transformation.

3) Reduce the pollution of shot peening to the workpiece

The reinforced steel shot has a high service life and crushing resistance, so that there is little dust remaining on the surface of the workpiece during the shot peening process (10-20 times less than the ordinary cast steel shot), which will greatly improve the adhesion after the coating.

4) Extend the use of wearing parts of the shot blasting machine life noodles

The reinforced steel shot has very high density and hardness, and is not easy to break. There is no damaged sand in the recycled steel shot, and the wear of the shot blasting machine and the protective plate is reduced to the minimum.

5) Reduce the shot peening to the workpiece pollution

Main chemical composition:

Silicon carbon = 0.45 0.85% = 0.70 1.20% mn = 0.80 1.50% sulfur phosphorus acuities were 0.04% and 0.04% or less

Specification: Diameter 0.3mm-1.5mm

Product hardness: HV555-605 (HRC52-55), HV610-670 (HRC55-59) and HV670-740 (HRC59-62)

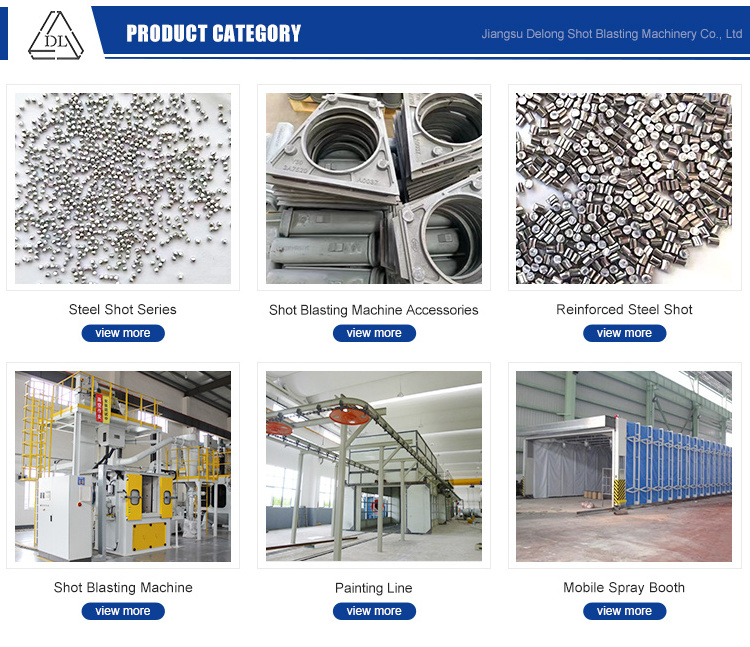

Jiangsu Delong Shot Blasting Machinery Co., Ltd. is a professional enterprise engaged in the research and development, production of shot blasting cleaning equipment, environmental protection equipment, shot blasting machine wear-resistant castings, stainless steel shot, reinforced steel shot, alloy steel shot, aluminum shot, copper shot and other metal abrasives. Our company provides one-stop services from design, casting, metalworking, assembly, and installation debugging. We have multiple production lines for stainless steel balls and reinforced steel balls, with complete supporting equipment such as medium frequency casting, machining centers, laser cutting, automatic welding, wire drawing machines, steel shot cutting machines, and grinding machines.

The reinforced steel shot products produced have the characteristics of strong adhesion, low loss, high brightness of the cleaned workpiece, good technical effect, uniform force, moderate hardness, tight internal organization, good elasticity, fatigue resistance, and wear resistance. Widely applicable for shot blasting, sandblasting and shot strengthening in special steel, gears, springs, container manufacturing, shipbuilding, aluminum die-casting, heat treatment, steel structures, steel pipes, aviation, pressure vessels, stone, etc.

We have been committed to providing various types of surface shot blasting equipment, reinforced steel shot, and stainless steel shot required for complete metal surface treatment and processing to industry customers. We are dedicated to product application research, deeply understanding customer

expectations, and using our process solutions to help customers achieve various creativity and goals.

The company produces and supplies multiple series of shot blasting equipment, including tracks, hooks, turntables, passes, and chain links. The company's newly launched B650A integrated track shot blasting machine, B1000MA integrated track blasting machine, and H2S0812 integrated suspension shot blasting machine are designed with integrated dust removal and electrical box, occupying small space, convenient and fast installation.

The entire room is covered with high manganese steel protective plates, with low failure rate, longer service life, no steel shot leakage or dust leakage, and good cleaning effect.

Q1. Can I have a sample order first?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity.

Q3. Do you have any MOQ for order?

A: Low MOQ, it's according to different products.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx . It usually takes 3-7 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order?

A: (1)let us know your requirements or application.

(2)We quote according to your requirements or our suggestions.

(3)customer confirms the samples and places deposit for formal order.

(4)We arrange the production.

Q6. Is it OK to print my logo on product?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our design layout.

Hot Searches