- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Aquaculture,Irrigation Dam,Landfill,Biogas

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BPM geosynthetics

-

Model Number:

-

BPMGH02

-

color:

-

black/white/green

-

raw material:

-

imported HDPE/LLDPE

-

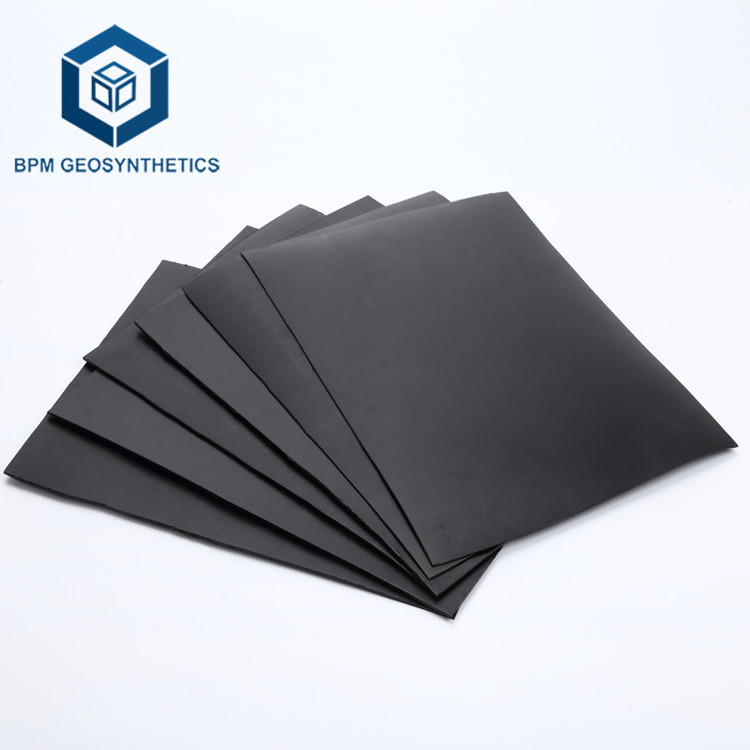

surface:

-

smooth

-

technics:

-

three-extrusion film-blowing process

-

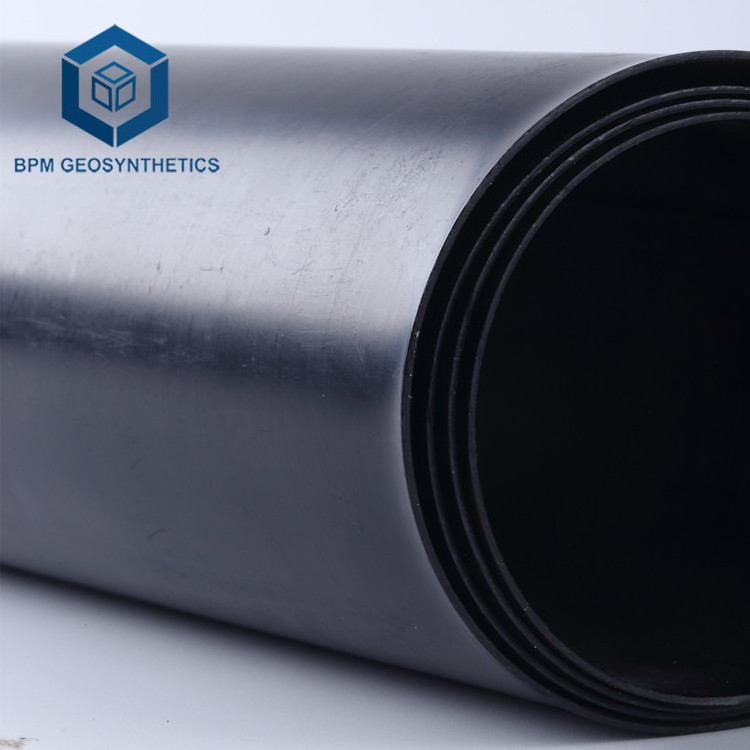

width:

-

2m to 8m

-

length:

-

50m,100m,150m,200m or upon your request

-

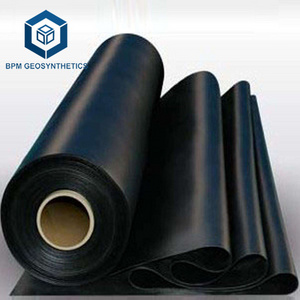

package:

-

woven plastic bags

-

application:

-

pond liner,dam liner,tank liner,landfill liner

-

standard:

-

ASTM GM13 or National Standard

-

keyword:

-

geomembrane hdpe 1mm

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Aquaculture,Irrigation Dam,Landfill,Biogas

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BPM geosynthetics

-

Model Number:

-

BPMGH02

-

color:

-

black/white/green

-

raw material:

-

imported HDPE/LLDPE

-

surface:

-

smooth

-

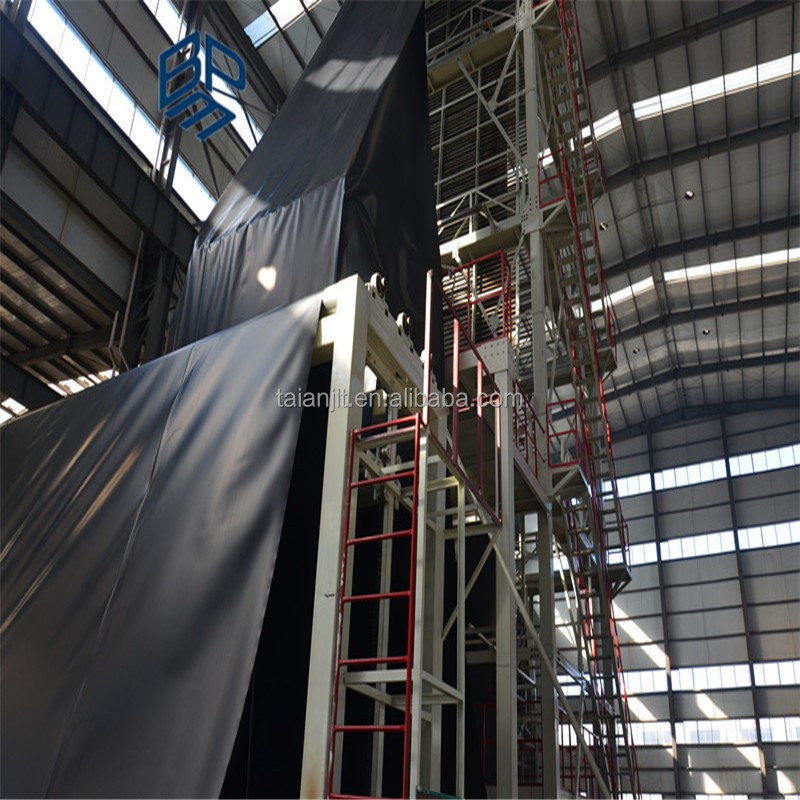

technics:

-

three-extrusion film-blowing process

-

width:

-

2m to 8m

-

length:

-

50m,100m,150m,200m or upon your request

-

package:

-

woven plastic bags

-

application:

-

pond liner,dam liner,tank liner,landfill liner

-

standard:

-

ASTM GM13 or National Standard

-

keyword:

-

geomembrane hdpe 1mm

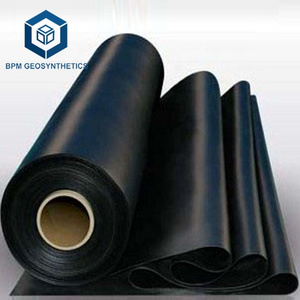

Geotextile Geomembane HDPE 0.2mm 1mm Thickness Plastic Sheet Three Layer Plastic Geomembrane Blown Film

When you want to choose waterproof material as your pool base,what is the key points you mostly care about,nothing but the following points:

Cost calculation

Flexibility

Elongation and tensile strength

Width and length per roll

Weather and UV resistance

Lifespan

Taking these into consideration,we recommend BPM HDPE geomembrane ,which has all the advantages and popularly used in a lot of applications,to be the priority choice among waterproof materials.

Let us introduce our product as follow:

BPM HDPE Geomembrane Description

Made from high density Polyethylene by blow film process .

Thickness from 0.3~3.0mm. Width : 4~7m. Length as customer demand.

Density: more than 0.94g/cm3

BPM HDPE Geomembrane Thickness

0.3mm,0.5mm,0.75mm,1.0mm,1.25mm,1.5mm,2.0mm,2.5mm,3.0mm

BPM HDPE Geomembrane Characteristics

1. Good flexibility

2. For service temperature range:-70°C~110°C

3. Corrosion resistance, aging resistance

4. Excellent environmental stress cracking resistance property

5. High tensile strength and elongation

BPM HDPE Geomembrane applied range

1. Municipal environmental projects, water conservancy projects

2. Landfill cap, mining heap leach pads

3. Pond liner, canal linings, tank linings, raw water treatment reservoirs, retention ponds

4. Waste water treatment lagoon, secondary containment tank.

Benefits of BPM HDPE aquaculture waterproof membrane

1.Environmental friendly non-toxic.

2.Construction cost lower than cement base.

3.Much more smooth than cement base,fish and shrimps are not liable to be injured.

4.Easy to install and remove the waste in pond.

5.The black membrane is preferred due to its lightproof and absorption of heat,restraining the grass from destroying the membrane while keeping warm for the creatures.

Steps to build fish pond

1.Dig a pool firstly.

2.Clear the site, remove the sundries.

3.Dig a anchor groove at the size of 50cm*50cm off the pool bank one meter, in order to install geomembrane easily.

4.Spread the membrane and weld the membranes into together.

5.Fasten it.

6.Water testing.

| Properties | Test Method | Test Value | |||||||

| 0.75mm | 1.0mm | 1.25mm | 1.50mm | 2.00mm | 2.5mm | 3.0mm | |||

| Maximum Deviation of thickness | -15% | ||||||||

| Density(min.ave.) | D1505/D792 | 0.940g/cc | |||||||

| Tensile Properties(min.ave) |

Yiled Strength; Break Strength |

D6693 | 11N/mm | 15N/mm | 18 N/mm | 22 N/mm | 29 N/mm | 37 N/mm | 44 N/mm |

| 20N/mm | 27 N/mm | 33 N/mm | 40 N/mm | 53 N/mm | 67 N/mm | 80 N/mm | |||

| Yiled Elongation | 12% | ||||||||

| Break Elongation | 700% | ||||||||

| Tear Resistance(min.ave) | D1004 | 93N | 125N | 156N | 187N | 249N | 311N | 374N | |

| Puncture Resistance(min.ave) | D4833 | 240N | 320N | 400N | 480N | 640N | 800N | 960N | |

| Carbon Black Content(range) | D4218 | 2.0-3.0% | |||||||

| Oxidative Induction Time(OIT)(min.ave) Standard OIT | D3895 | 100min | |||||||

| Oven Aging at 85℃ Standard OIT(min.ave.)-% retained after 90 days | D5721 D3895 | 55% | |||||||

| UV Resistance High Pressure OIT(min.ave)-% retained after 1600hrs | D3895 D5885 | 50% | |||||||

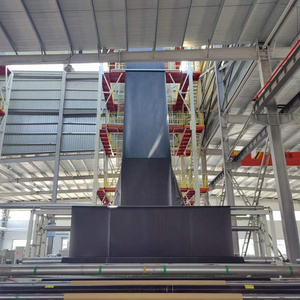

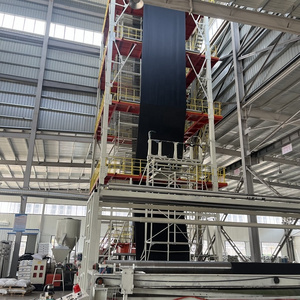

Factory Show

Welding Machines for Sale