- Product Details

- {{item.text}}

Quick Details

-

Manufacturer:

-

Yes

-

OEM:

-

Accept

-

Brand:

-

STRONG

-

Model:

-

ZY-ID1500

-

Function:

-

High Frequency Induction Plastic Welding Machine

-

Operation Way:

-

Semi-Automatic

-

ODM:

-

Accept

-

Cetificate:

-

CE Approved

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

500 KG

-

Machine Type:

-

High Frequency Induction Welding Machine

-

Manufacturer:

-

Yes

-

OEM:

-

Accept

-

Brand:

-

STRONG

-

Model:

-

ZY-ID1500

-

Function:

-

High Frequency Induction Plastic Welding Machine

-

Operation Way:

-

Semi-Automatic

-

ODM:

-

Accept

-

Cetificate:

-

CE Approved

Product Description

The welding process uses an induction coil to excite and heat electromagnetically susceptible material at the joint interface and melt the thermoplastic. The susceptible material can be contained in a gasket placed between the welding surface, or within the actual components of a composite material. Its usage is common for large, unusually shaped, or delicate parts that would be difficult to weld through other methods such as ultrasonic welding, spin welding and hot plate welding.

Equipment:

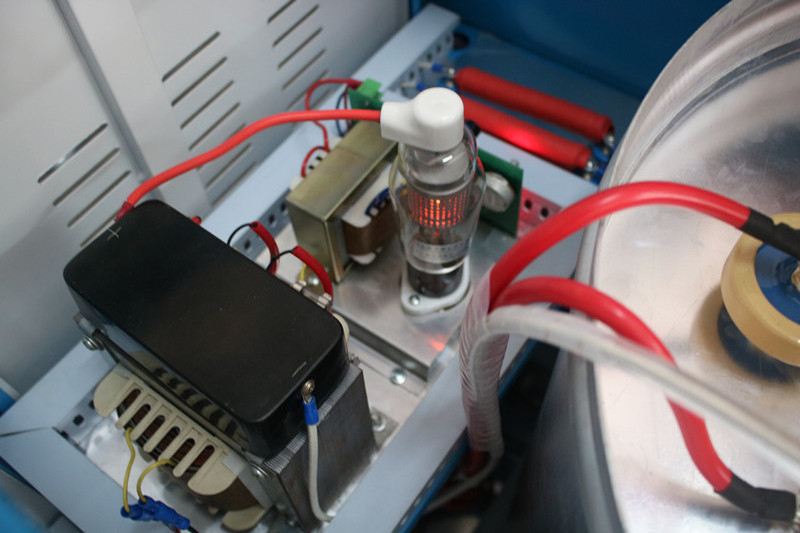

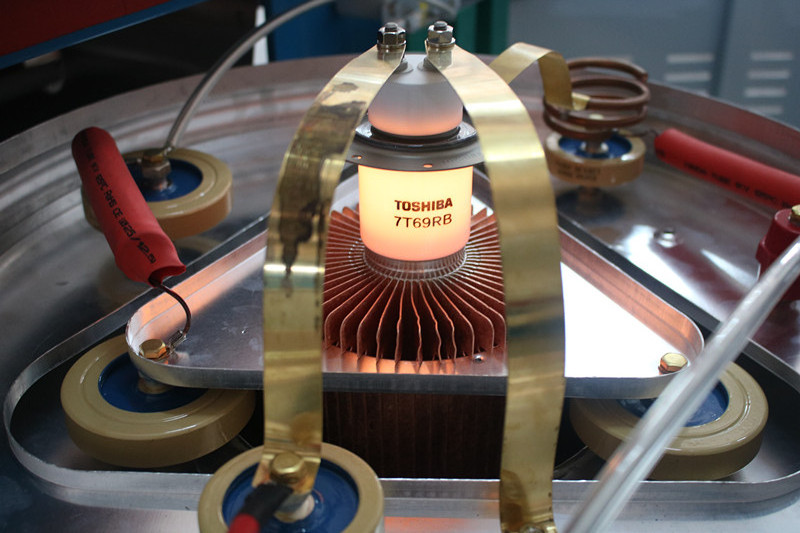

An induction generator is used to produce high frequency current in the range of 2-10 Mhz. The range used is regulated by the FCC to avoid interference with broadcast signals.

An induction coil converts the high frequency current from the induction generator into the necessary alternating magnetic field. A single turn coil may be used when space is limited, however multiturn coil designs are more common due to their generation of a stronger and deeper penetrating magnetic field. Split coil designs are also available, which may be disassembled to fully surround a large part such as plastic piping. The high currents used in induction welding produce large amounts of heat in the coil. To avoid overheating, the coil turns are made with hollow tubing, and water is circulated during welding. Coil heat is dissipated by an attached heat exchange.

Fixtures are used to hold the parts in position during welding. One fixture is fixed and the other movable so that a press may apply and maintain pressure during heating and cooling.

Advantages:

1. Implant induction welding does not require physical contact with a heat source, so it is useful for joining

components with unusual dimensions or delicate surfaces.

2. The induction coil can be moved continuously to heat the entire surface of long joints. Extremely large parts can be effectively welded using this method.

3. Heat generation is limited to the exact area where it is required for joining, so thermal str

Our Advantages

* Safety device- Anti-Spark System

* TOSHIBA(CANON) Oscillation Tube

* Easily Adjustable Tuner

Machine output power can be adjusted at the tuner according to electrode size and material thickness. In addition, other control devices and special electrical circuits have cut down required welding time considerably to raise the machine productivity.

*

Jamming Prevention Device

*

*Shuttle Working Station

Machine adopts with shuttle working station, one machine have two working stations, when one working station is welding, and other one station can be prepared the material for welding. Greatly improve working efficiency.

Application

Scope of application:

Household electrical products, Musical Instruments, stationery, toys, car parts and other metal plastic products fusion

processing. For example, kettle type PP container, auto parts type PP container, plastic speaker net embedding, metal mesh speakers, audio, hardware products, plastic products, electronic products with plastic embedding metal fusion. The water tightness and air tightness of PP containers of water bottles and auto parts are good after planting by high frequency horn net embedding machine. It can also be used for embedding horn metal mesh, metal to plastic embedding, etc.

Machine Parameter

|

Specifications

|

ZY-1500

|

|

Biggest oscillatory power

|

15KW 25KW

|

|

Biggest welding perimeter

|

950mm 1400mm

|

|

Input voltage

|

AC220V 50/60HZ AC380V 50/60HZ

|

|

Frequency

|

30-80KHZ 30-80KHZ

|

|

Weld period time

|

0.1-9.9S 0.1-9.9S

|

|

Cooling system

|

≥0.2Mpa 2-5L/min ≥0.2Mpa 2-5L/min

|

|

Air supply

|

0-1Mpa 0-1Mpa

|

|

Net weight

|

550kg

|

|

machine size

|

700*1100*2050MM

|

|

Working Table Size

|

400*600MM

|

|

Machine Dimension

|

1850*1220*1550MM

|

|

Machine Net Weight

|

450KG

|

Packing & Delivery

Packing:

Machine packing inside is plastic films and outside is fumigation wooden case.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Delivery:

For machines are big and heavy parcel, and different country with different delivery cost,so we suggest below delivery solution:

1. Over 1CBM or 100KG, we suggest send by Sea.

2. Below 1CBM or 100KG, we suggest send by Air.

3. Below 0.5CBM or 50KG, we suggest send by Express.

The price show on our website just the machine EXW price, please contact us for confirm delivery cost before you place order.

1. Over 1CBM or 100KG, we suggest send by Sea.

2. Below 1CBM or 100KG, we suggest send by Air.

3. Below 0.5CBM or 50KG, we suggest send by Express.

The price show on our website just the machine EXW price, please contact us for confirm delivery cost before you place order.

Hot Searches