- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2550*1650*2200

-

Weight (KG):

-

3200

-

Power (kW):

-

4.4

-

Type:

-

Surface Grinding Machine

-

Key Selling Points:

-

Multifunctional

-

After-sales Service Provided:

-

No overseas service provided, Online support, Video technical support

-

Product name:

-

MY4080 Grinder

-

Other name:

-

Surface grinding machine yunnan MY4080 Grinding machines manufacturer

-

Key words:

-

grinding equipment

-

Model:

-

MY4080

-

Color:

-

automatic grinding machine

-

Motor:

-

4.4KW

-

Precision:

-

High Accuracy

-

Worktable size (L * W):

-

800*400

-

Power(W):

-

4.4KW

-

Table Travel (Y) (mm):

-

480 mm

-

Table Travel (X) (mm):

-

900 mm

-

Surface Roughness(μm):

-

0.03 μm

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Luzhong Machine

-

Voltage:

-

Requirement

-

Dimension(L*W*H):

-

2550*1650*2200

-

Weight (KG):

-

3200

-

Power (kW):

-

4.4

-

Type:

-

Surface Grinding Machine

-

Key Selling Points:

-

Multifunctional

-

After-sales Service Provided:

-

No overseas service provided, Online support, Video technical support

-

Product name:

-

MY4080 Grinder

-

Other name:

-

Surface grinding machine yunnan MY4080 Grinding machines manufacturer

-

Key words:

-

grinding equipment

-

Model:

-

MY4080

-

Color:

-

automatic grinding machine

-

Motor:

-

4.4KW

-

Precision:

-

High Accuracy

-

Worktable size (L * W):

-

800*400

-

Power(W):

-

4.4KW

-

Table Travel (Y) (mm):

-

480 mm

-

Table Travel (X) (mm):

-

900 mm

-

Surface Roughness(μm):

-

0.03 μm

-

Certification:

-

CE ISO

Product Description

The main performance characteristics:

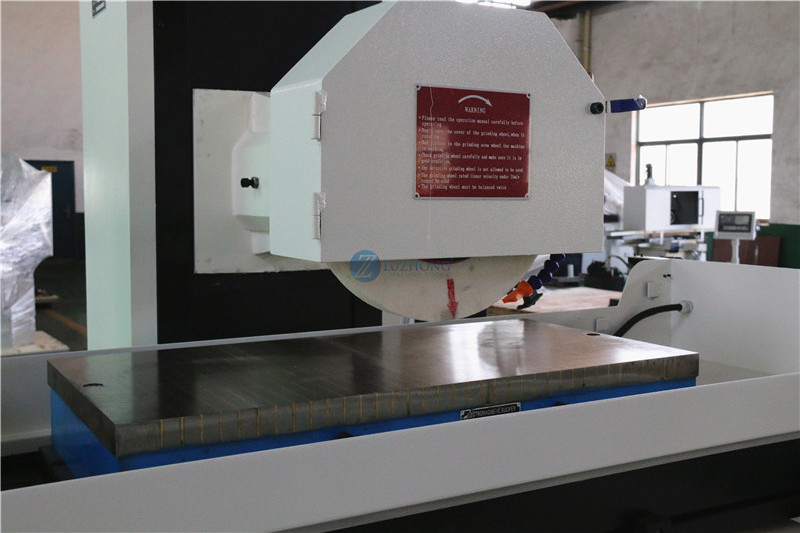

1. The structure of the machine tool is reasonable, large machine tool bed weight, excellent stability, using the cross saddle

structure, good rigidity, has the advantages of beautiful appearance and convenient operation.

2. Horizontal movement of working table (before and after) by servo motor drive, precision ball screw drive, to ensure accuracy,

accurate positioning, in accordance with the procedures of automatic feeding, automatically and fast forward and rewind functions.

3. Working table vertical (or so) movement, the use of a V a flat guide, and the artificial precision shovel flowers, the use of

hydraulic transmission, stable operation.

4. The grinding head up and down movement driven by a servo motor, which can achieve precise positioning accuracy, automatic feed

and fast lifting function.

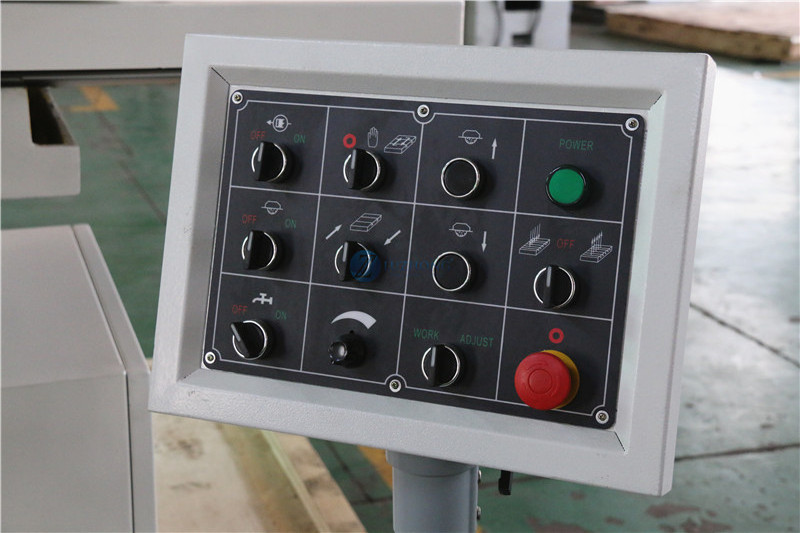

5. The Guangzhou CNC system GSK96 and two axis NC, according to the actual processing conditions free programming, with pulse

wheel, X and Z axis feed can be free to switch freely.

6. Machine adopts full enclosed casing, can completely cover the whole of the working area, effectively prevent the splash of the

cooling liquid and iron filings, and according to the requirements of clients connected ceiling spray dust removal device.

(optional)

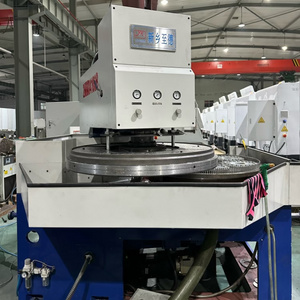

7. The characteristics of the CNC grinding machine is realize three-axis full automation, the second axis plane grinder while

reducing the labor intensity of the operator, but also a single stand-alone operation, three axis automatic surface grinder, a

worker can be 3 - 5 machines are operating at the same time, greatly reduce the labor cost, especially when the batch processing,

the benefit is more remarkable.

Application:

Applicable to all kinds of processing machinery, auto parts, fixture, magnetic steel, mould parts processing industry.

The machine tool can be made of grinding steel, iron, ceramics and non-ferrous metal parts.

Product main technical parameters:

1. The structure of the machine tool is reasonable, large machine tool bed weight, excellent stability, using the cross saddle

structure, good rigidity, has the advantages of beautiful appearance and convenient operation.

2. Horizontal movement of working table (before and after) by servo motor drive, precision ball screw drive, to ensure accuracy,

accurate positioning, in accordance with the procedures of automatic feeding, automatically and fast forward and rewind functions.

3. Working table vertical (or so) movement, the use of a V a flat guide, and the artificial precision shovel flowers, the use of

hydraulic transmission, stable operation.

4. The grinding head up and down movement driven by a servo motor, which can achieve precise positioning accuracy, automatic feed

and fast lifting function.

5. The Guangzhou CNC system GSK96 and two axis NC, according to the actual processing conditions free programming, with pulse

wheel, X and Z axis feed can be free to switch freely.

6. Machine adopts full enclosed casing, can completely cover the whole of the working area, effectively prevent the splash of the

cooling liquid and iron filings, and according to the requirements of clients connected ceiling spray dust removal device.

(optional)

7. The characteristics of the CNC grinding machine is realize three-axis full automation, the second axis plane grinder while

reducing the labor intensity of the operator, but also a single stand-alone operation, three axis automatic surface grinder, a

worker can be 3 - 5 machines are operating at the same time, greatly reduce the labor cost, especially when the batch processing,

the benefit is more remarkable.

Application:

Applicable to all kinds of processing machinery, auto parts, fixture, magnetic steel, mould parts processing industry.

The machine tool can be made of grinding steel, iron, ceramics and non-ferrous metal parts.

Product main technical parameters:

|

Specifications

|

|

Units

|

MY4080

|

|

|

Table size (L * W)

|

|

mm

|

800*400

|

|

|

Table travel (L * W)

|

|

mm

|

900*480

|

|

|

Table T slot (number * width)

|

|

mm

|

3*14

|

|

|

Distance spindle center line to table

|

|

mm

|

600

|

|

|

Wheel size (O. D * W * I. D.)

|

|

mm

|

350*40*127

|

|

|

Wheel speed 50HZ

|

|

r/min

|

1450

|

|

|

Wheel speed 60HZ

|

|

r/min

|

1680

|

|

|

Table longitudinal moving speed

|

|

m/min

|

3-25

|

|

|

Table corss moving

|

Continuous feed speed

|

mm/min

|

600

|

|

|

|

Intermittent feed speed

|

mm/t

|

0-8

|

|

|

|

Hand feed per rev

|

mm/rev

|

5

|

|

|

|

Hand feed per gra

|

mm/gra

|

0.02

|

|

|

Head vertical moving

|

Hand feed per rev

|

mm/rev

|

0.8/1.0

|

|

|

|

Hand feed per gra

|

mm/gra

|

0.01

|

|

|

|

Fast moving speed

|

mm/min

|

500

|

|

|

Spindle motor power

|

|

kw

|

4

|

|

|

Coolant motor power

|

|

w

|

125

|

|

|

Head lifting motor

|

|

w

|

180

|

|

|

Hydraulic system

|

Hydraulic motor

|

kw

|

2.2

|

|

|

Machining surface parallelism

|

|

mm

|

0.005/300

|

|

|

Surface roughness

|

|

um

|

Ra0.4

|

|

|

Electro Magnetic chuck size

|

|

mm

|

800*400

|

|

|

Machine weight

|

|

kg

|

2800/3200

|

|

|

Overall dimension(L * W * H)

|

|

mm

|

2460*2140*2150

|

|

Details Display

Hot Searches