- Product Details

- {{item.text}}

Quick Details

-

Size:

-

595x595;605x605;600x1200;1200x2400

-

Thickness:

-

6mm-18mm

-

Acoustics:

-

Sound Insulation

-

Unit Area Quanlity:

-

<6.5kg/m2(7mm); <7.5kg/m2(8mm); <8.5kg/m2(9mm)

-

Load at break:

-

7.5mm≥110N; 8mm≥120N; 9mm≥140N

-

Fireproof Performance:

-

B1

-

RH:

-

<90%

-

Standard:

-

EN 13964:2007

Quick Details

-

Place of Origin:

-

Shandong, China

-

Type:

-

Ceiling Tiles

-

Item:

-

PVC Laminated Gypsum Ceiling

-

Size:

-

595x595;605x605;600x1200;1200x2400

-

Thickness:

-

6mm-18mm

-

Acoustics:

-

Sound Insulation

-

Unit Area Quanlity:

-

<6.5kg/m2(7mm); <7.5kg/m2(8mm); <8.5kg/m2(9mm)

-

Load at break:

-

7.5mm≥110N; 8mm≥120N; 9mm≥140N

-

Fireproof Performance:

-

B1

-

RH:

-

<90%

-

Standard:

-

EN 13964:2007

Why Choose Us

Factory Data

Established : 1996

Manufacturing: 6

Factory area :

40000m2

Number of Employee :

100

office staff

200

factory staff

Automatic Production Lines:

35

Production capacity :

12000m2

per day (aluminum ceiling)

Product Supply : Ceiling System / Wall Partition System

Projects : Apartments , villas, Hotel Shopping Mall, Hostpital ect

We have our own research and development and design team

World Wide

PRANCE have exported products more than

120

countries.

More than 5580 high-quality customers is purchasing from Prance.

Europe: 12%

America: 10%

Africa: 22%

Asia: 48% ( Mid-East:26%)

Oceania:8%

Prance

75

Automatic Production Lines

108

Countries Exporting To

5680

High-quality Customers

Prance's business all over the world

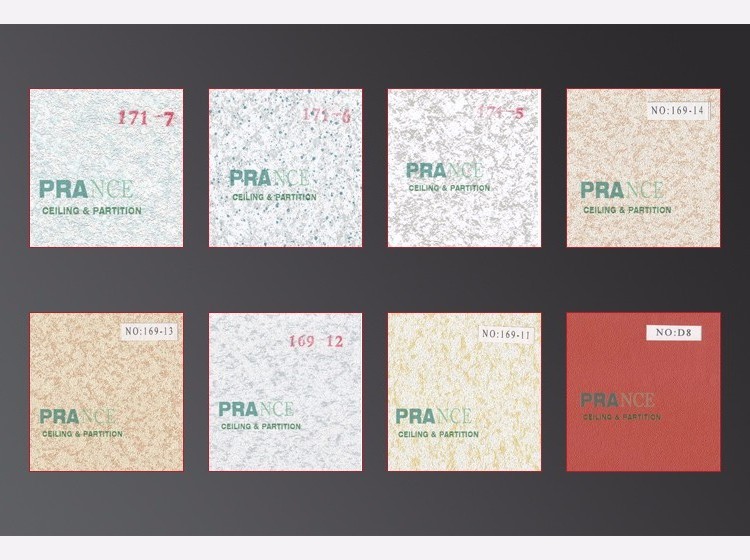

paper faced PVC laminated gypsum ceiling tiles price

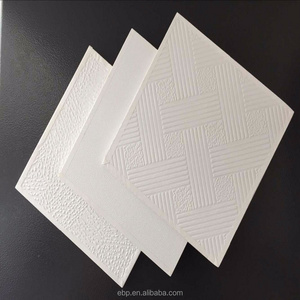

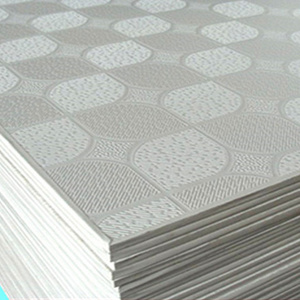

Gypsum Board of ceiling & wall partition system

PRANCE System is a modern, non-load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

Exquisite, Modern and Adjustable.

PRANCE drywall system provides smooth, seamless and crack-free wall surface. Thanks to the distinctive property of PRANCE gypsum Board, it allows easy further decoration by either painting or wallpaper work. Moreover, a renovation can be done easily without any disturbance of office building structure.

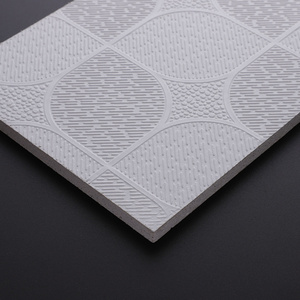

Durable and Standard Quality

Materials and accessories of PRANCE wall system are manufactured by state of the art technology in accordance with international standards, such as, British Standard and The American Society for Testing and Materials. Customers therefore can be assured of safety, standard quality and high durabiltity of PRANCE Wall systems.

Lightweight, Easy to Install and Economic

PRANCE wall weight much less than masonry partitions of comparable thickness, thus providing real savings in structural design. This enables quick and easy installation, and produces time and cost savings.

Specially Designed and Patented Materials of Gyproc

High quality galvanized PRANCE frame metal sections of drywall system are manufactured by state of the art technology called drywall STEEL, to reinforce the cross section of metal sections. C-Stud is also specially designed to be easy when connected, which suits applications requiring extra strength or for length extension of C-Stud. Ready-punched holes from factory provide excellent incorporation of services.

Applicable to Various Usages as Required

PRANCE wall system can be designed to suit various types of office application.

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

| Convenient Construction | The plaster board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

| Raw material | The gypsum board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

| Size | 595x595 |

| 605x605 | |

| 1200x2400 | |

| 1220x2440 | |

| Thickness | 7,7.5,8,9,9.5,10,12,12.5,13,15,15.9 |

| Surface treatment | Paper/PVC laminated/foil back |

| Production capacity | 10,000m2/day |

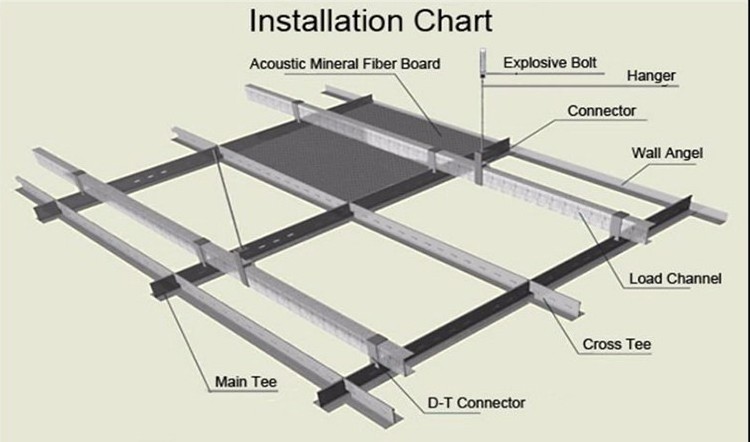

Step 1: Construct a pair of T-braces from 2 X 4s about an inch longer than the distance from floor to ceiling. Nail 2 X 4s about 3 feet long to one end of each longer 2 X 4 to form the Ts. Alternately, adjustable T-braces can be rented.

Step 2: Cut drywall panels to size. Use a sharp utility knife along a straightedge to cut drywall. After you make the cut through the face paper, place the board over a length of 2 X 4 laid flat on the floor, or some other type of support, and snap the scored section down. The gypsum core will break along the line you cut. Then turn the panel over, cut the paper on the other side, and smooth the rough edges with very coarse sandpaper on a sanding block.

Step 3: Install drywall panels on the ceiling. If possible, try to span the entire width with a single sheet of wallboard to reduce the number of joints. Position and wedge the T-braces against the drywall sheet to hold it in place until you finish nailing it.

Step 4: Drive nails at 6-inch intervals into all the joists covered by the sheet. Start in the center of the drywall panel and work out. Give each nail an extra hammer blow to dimple the surface slightly without breaking the face paper.

Step 5: When the ceiling is finished, cut and install wall panels. Carefully measure for any cutouts in the drywall, including electrical outlets, switches, or light fixtures. To make cutouts, draw a pattern of the cutout on the wallboard, drill a hole on the pattern line, and then use a keyhole saw to follow the pattern.

Step 6: Space the nails 6 inches apart along studs, but start nailing 4 inches from the ceiling. Butt the wall panels against the ceiling sheets. Dimple all nails. Nail metal outside cornerbeads to cover any outside corners.