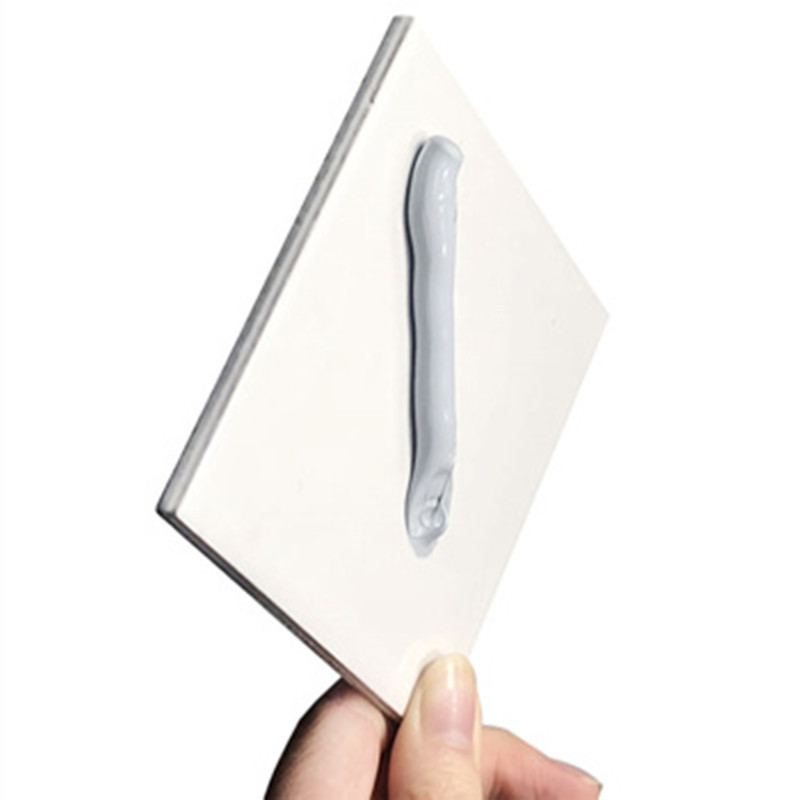

MS series adhesives are based on silane-modified polyether resins, which have good sealing and cohesion. They are non corrosive,

non polluting, and eco-friendly to substrates, and can seal and bond well to various substrates such as metals, plastics, wood,

glass, etc.

non polluting, and eco-friendly to substrates, and can seal and bond well to various substrates such as metals, plastics, wood,

glass, etc.