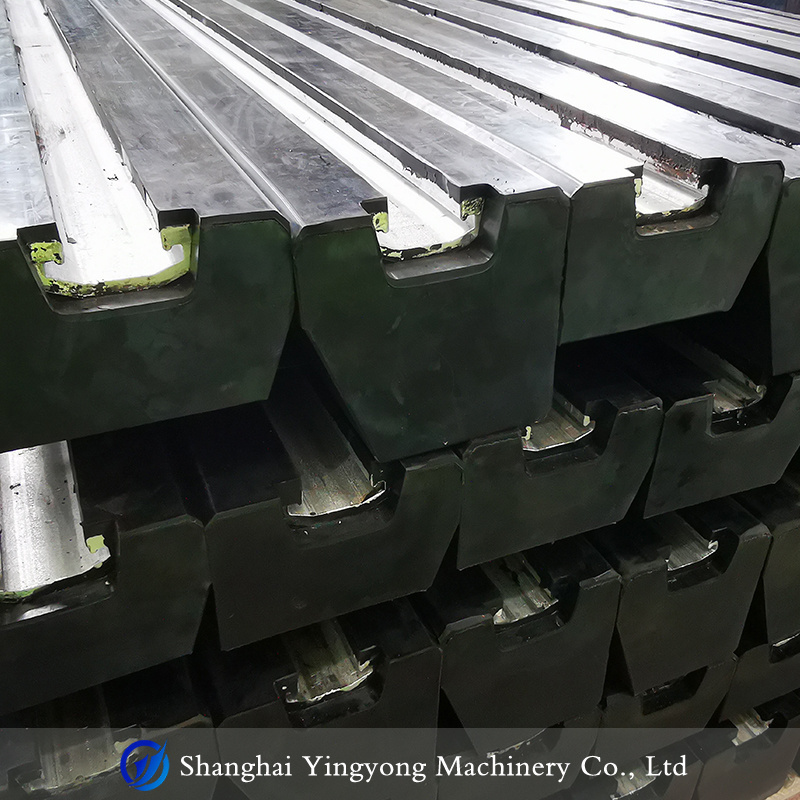

A complete set of ball mill rubber liner consists of end-liner (grid type is lattice liner), ends lifter bar, the center ring (grid type is center liner), fillers, barrel lifter bar (also known as layering), cylinder liner, manhole, fasteners and other

parts.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

500 KG

-

Origin:

-

shanghai, China

-

After-sales Service:

-

Online support

-

Quality:

-

high quality low cost

-

Color:

-

Customer Requirement

-

Price:

-

Negotiatable

-

Usage:

-

ball mill

-

Processing Type:

-

Casting

-

Material:

-

High Manganese Steel

-

Product name:

-

Ball Mill Liner

Quick Details

-

Marketing Type:

-

New Product

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YINGYONG

-

Weight:

-

500 KG

-

Origin:

-

shanghai, China

-

After-sales Service:

-

Online support

-

Quality:

-

high quality low cost

-

Color:

-

Customer Requirement

-

Price:

-

Negotiatable

-

Usage:

-

ball mill

-

Processing Type:

-

Casting

-

Material:

-

High Manganese Steel

-

Product name:

-

Ball Mill Liner

Product Description

With the development of modern production, the diameter of the ball mill equipment is getting larger and larger. The ball mill with a diameter of about five meters has been widely used in production, so the quality requirements of the lining plate and the ball are getting higher and higher

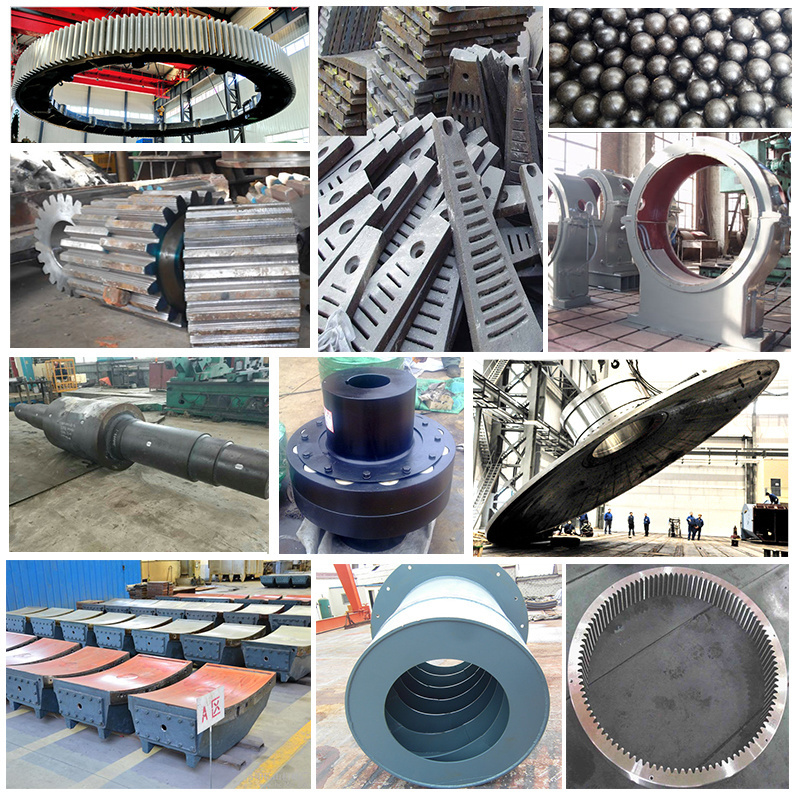

Processing and manufacturing strength

We have several sets of hobbing machines with a diameter of 3m-10m; several sets of various submerged arc welding machines; we have processing equipment such as heat treatment electric furnaces and CNC vertical lathes and CNC lathes, with mechanical

performance testing, impact testing machines, UT and MT flaw detection equipment Complete testing system

performance testing, impact testing machines, UT and MT flaw detection equipment Complete testing system

|

Product Name:

|

certification:

|

advantage:

|

color:

|

|

ball mill liner

|

IOS

|

high quality low cost

|

customer's request

|

|

Mould process:

|

Inspection:

|

Processing:

|

price:

|

|

casting or forging

|

Raw material inspection, UT,physical property test,dimension inspection

|

casting, rough machining, QT, finish machining

|

Can discuss

|

Production Process Introduction

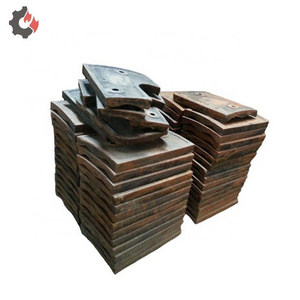

Making wooden molds, modeling, smelting and pouring, heat preservation, pit clearing, heat treatment, roughing, finishing,inspection, and delivery

Product Display

Quality Control

Quality Assurance

1. Strict inspection before leaving the factory to ensure that the surface hardness HB meets the requirements of the drawings.

2. The main techniques of flaw detection are: ultrasonic flaw detection (UT), magnetic particle flaw detection (MT), and color flaw detection (PT). Overall, it can reach level 3 flaw detection, and key parts can reach level 2 flaw detection.

2. The main techniques of flaw detection are: ultrasonic flaw detection (UT), magnetic particle flaw detection (MT), and color flaw detection (PT). Overall, it can reach level 3 flaw detection, and key parts can reach level 2 flaw detection.

Product quality inspection

1. According to the requirements of the drawings, control the casting size to ensure the machining allowance and accuracy requirements.

2. Advanced flaw detection equipment is used to precisely control the internal quality of castings.

3. Tempering treatment is performed to ensure the strength and toughness of the equipment and improve the mechanical performance.

2. Advanced flaw detection equipment is used to precisely control the internal quality of castings.

3. Tempering treatment is performed to ensure the strength and toughness of the equipment and improve the mechanical performance.

Company Introduction

Our Business

Customer Visiting

P roduct Packaging And Shipment

Anti-rust paint is applied to the processing parts such as the end face and protected by protective plates. The equipment is packed in an overall iron frame and covered with protective rain cloth.

After-sales service

Delivery provides a full set of test reports, material certificates, certifications, etc., and provides technical guidance installation services.

FAQ

Hot Searches