- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

HEB

-

Model Number:

-

SS-512

-

Brand Name:

-

R&K

-

Product name:

-

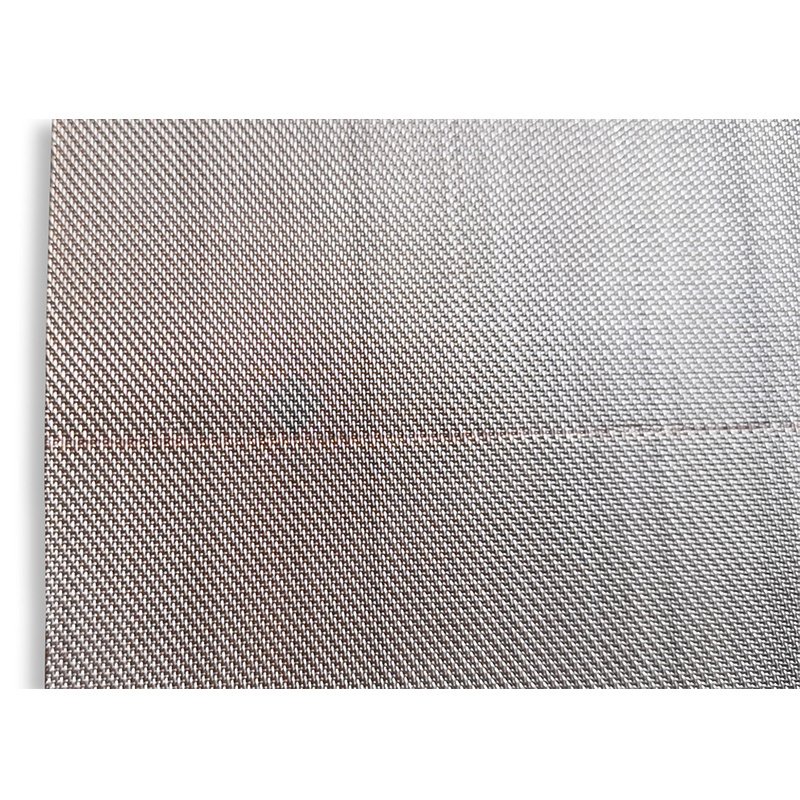

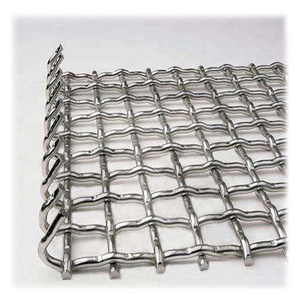

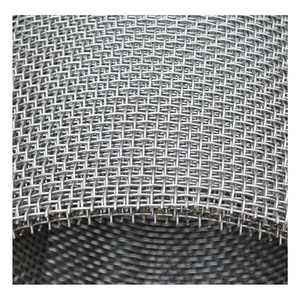

304 316 Stainless Steel Wire Mesh Screen Plain Weave Woven Wire Mesh

-

Usage:

-

Construction

-

Color:

-

Silver

-

Feature:

-

Corrosion Resistance

-

Hole shape:

-

Square Hole

-

Length:

-

30m/roll

-

Width:

-

1.0m

-

Packing:

-

Wooden Case

-

MOQ:

-

1 Square Meter

-

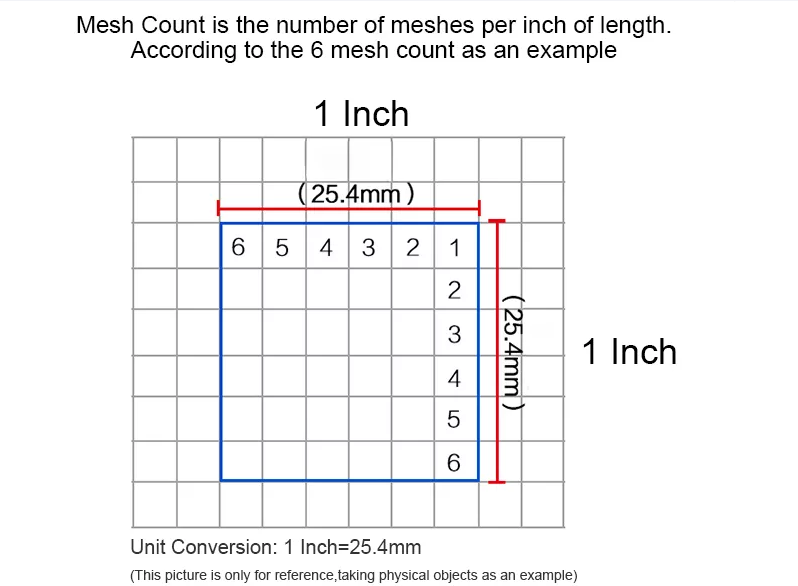

Mesh count:

-

100 mesh

Quick Details

-

Material:

-

STAINLESS STEEL WIRE

-

Type:

-

Wire Cloth

-

Application:

-

Protecting Mesh

-

Place of Origin:

-

HEB

-

Model Number:

-

SS-512

-

Brand Name:

-

R&K

-

Product name:

-

304 316 Stainless Steel Wire Mesh Screen Plain Weave Woven Wire Mesh

-

Usage:

-

Construction

-

Color:

-

Silver

-

Feature:

-

Corrosion Resistance

-

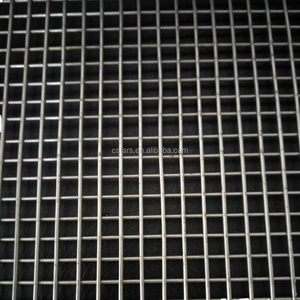

Hole shape:

-

Square Hole

-

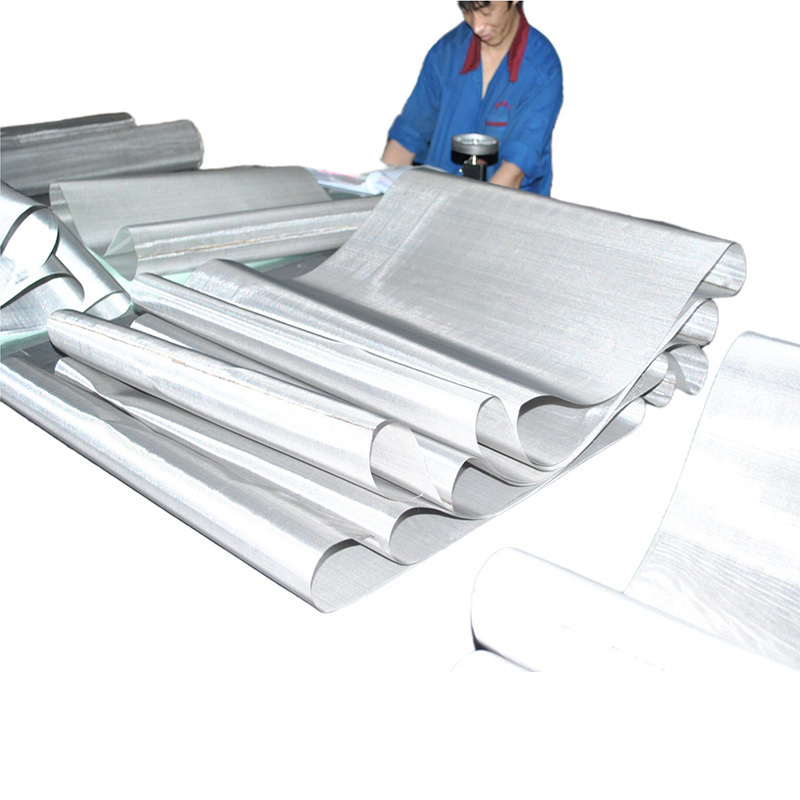

Length:

-

30m/roll

-

Width:

-

1.0m

-

Packing:

-

Wooden Case

-

MOQ:

-

1 Square Meter

-

Mesh count:

-

100 mesh

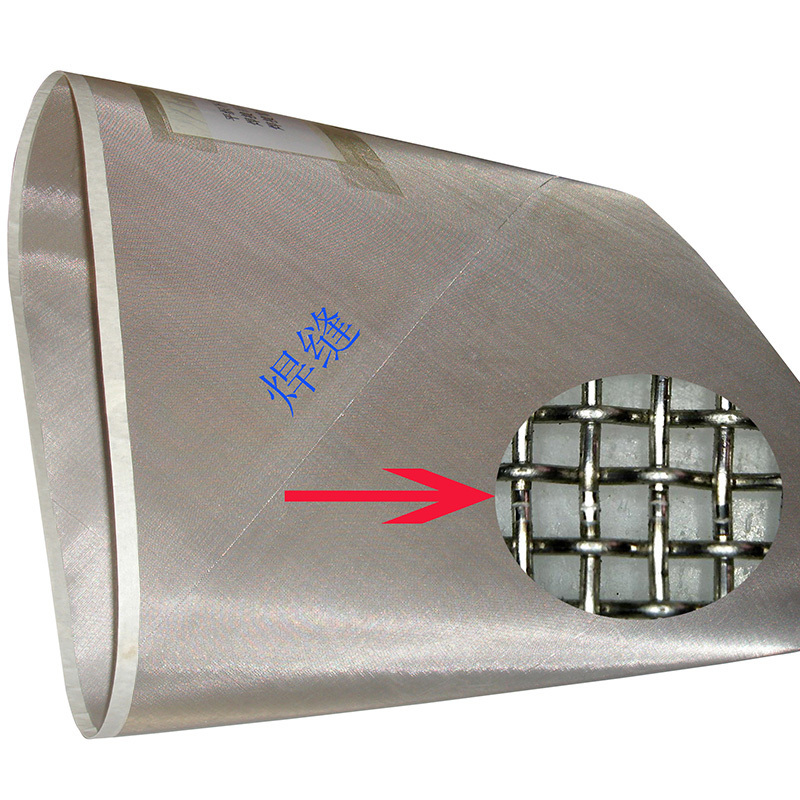

304 316 Stainless Steel Metal Paper Machine Cylinder Welded Screen Wire Mesh

Product Description

Specification

|

item

|

value

|

|

Place of Origin

|

HEB

|

|

Material

|

STAINLESS STEEL WIRE

|

|

Type

|

Wire Cloth

|

|

Application

|

Protecting Mesh

|

|

Weave Style

|

Plain Weave

|

|

Technique

|

woven

|

|

Model Number

|

SS-512

|

|

Brand Name

|

R&K

|

|

Processing Service

|

Decoiling

|

|

Delivery Time

|

8-14 days

|

|

Product name

|

Plain Weave Silver Color Filter Mesh Cloth Stainless Steel Wire Mesh

|

|

Usage

|

Construction

|

|

Color

|

Silver

|

|

Feature

|

Corrosion Resistance

|

|

Hole shape

|

Square Hole

|

|

Length

|

30m/roll

|

|

Width

|

1.0m

|

|

Packing

|

Wooden Case

|

|

MOQ

|

1 Square Meter

|

|

Mesh count

|

100 mesh

|

|

Mesh/Inch

|

Wire Diameter

|

|

Aperture

|

|

Open Area

|

Weight

(kg/Square meter) |

||

|

|

Inch

|

MM

|

Inch

|

MM

|

|

|

||

|

1×1

|

0.08

|

2.03

|

0.92

|

23.37

|

92

|

2

|

||

|

2×2

|

0.063

|

1.6

|

0.437

|

11.1

|

87.4

|

2.5

|

||

|

3×3

|

0.054

|

1.37

|

0.279

|

7.09

|

83.8

|

2.7

|

||

|

4×4

|

0.047

|

1.19

|

0.203

|

5.16

|

81.2

|

2.7

|

||

|

5×5

|

0.041

|

1.04

|

0.159

|

4.04

|

79.5

|

2.6

|

||

|

10×10

|

0.025

|

0.64

|

0.075

|

1.91

|

74.9

|

2

|

||

|

12×12

|

0.02

|

0.508

|

0.063

|

1.6

|

75.9

|

1.5

|

||

|

14×14

|

0.02

|

0.508

|

0.051

|

1.3

|

71.9

|

1.8

|

||

|

16×16

|

0.018

|

0.457

|

0.0445

|

1.13

|

71.2

|

1.6

|

||

|

18×18

|

0.017

|

0.432

|

0.0386

|

0.98

|

69.4

|

1.6

|

||

|

20×20

|

0.02

|

0.24

|

0.03

|

0.76

|

76

|

0.56

|

||

|

20×20

|

0.016

|

0.33

|

0.034

|

0.86

|

72.2

|

1.1

|

||

|

30×30

|

0.012

|

0.305

|

0.0213

|

0.54

|

63.9

|

1.4

|

||

|

30×30

|

0.0094

|

0.24

|

0.0243

|

0.62

|

72.1

|

0.84

|

||

|

40×40

|

0.01

|

0.254

|

0.015

|

0.38

|

59.9

|

1.3

|

||

|

50×50

|

0.0055

|

0.14

|

0.0145

|

0.368

|

72.4

|

0.48

|

||

|

60×60

|

0.0047

|

0.12

|

0.012

|

0.303

|

71.6

|

0.42

|

||

|

60×60

|

0.0059

|

0.15

|

0.0107

|

0.273

|

64.5

|

0.65

|

||

|

80×80

|

0.0055

|

0.14

|

0.0069

|

0.117

|

45.5

|

0.76

|

||

|

100×100

|

0.0045

|

0.114

|

0.0055

|

0.14

|

55.1

|

0.59

|

||

|

100×100

|

0.004

|

0.102

|

0.006

|

0.152

|

59.8

|

0.49

|

||

|

120×120

|

0.0028

|

0.07

|

0.0057

|

0.147

|

67.7

|

0.29

|

||

|

150×150

|

0.0024

|

0.06

|

0.0043

|

0.11

|

64.7

|

0.26

|

||

|

150×150

|

0.0028

|

0.07

|

0.0039

|

0.1

|

58.8

|

0.38

|

||

|

165×165

|

0.0019

|

0.05

|

0.0041

|

0.104

|

67.5

|

0.2

|

||

|

180×180

|

0.0019

|

0.05

|

0.0035

|

0.091

|

64.5

|

0.22

|

||

|

180×180

|

0.0024

|

0.06

|

0.0031

|

0.081

|

57.4

|

0.32

|

||

|

200×200

|

0.0019

|

0.05

|

0.003

|

0.077

|

60.6

|

0.24

|

||

|

200×200

|

0.0024

|

0.06

|

0.0026

|

0.067

|

52.7

|

0.35

|

||

|

250×250

|

0.0016

|

0.04

|

0.0024

|

0.0616

|

60.6

|

0.2

|

||

|

270×270

|

0.0016

|

0.04

|

0.0021

|

0.054

|

57.4

|

0.21

|

||

|

300×300

|

0.0016

|

0.04

|

0.0018

|

0.045

|

53.5

|

0.23

|

||

|

325×325

|

0.0014

|

0.035

|

0.0017

|

0.0432

|

55.3

|

0.2

|

||

|

400×400

|

0.0012

|

0.03

|

0.0013

|

0.0335

|

52.7

|

0.18

|

||

|

500×500

|

0.0009

|

0.025

|

0.001

|

0.0258

|

50.7

|

0.15

|

||

|

635×635

|

0.0007

|

0.018

|

0.0008

|

0.022

|

55

|

0.1

|

||

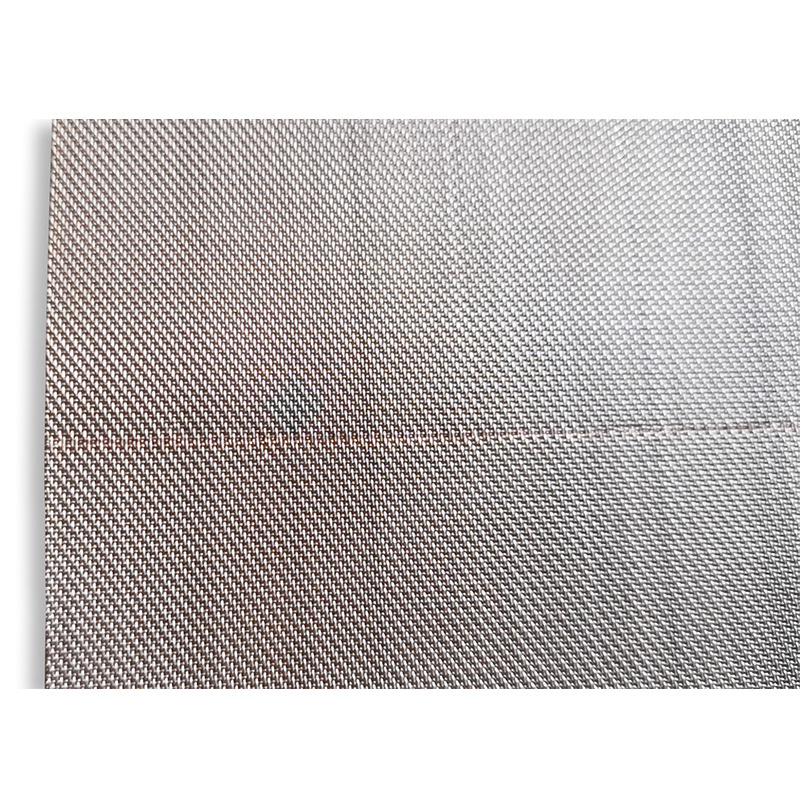

Feature

Extensive filtration range from over 6" pore size to nominal 1 micron

Tightly controlled, precise aperture

Smooth surface - no sharp edges, burrs on the screening surface

Can be used under high pressure

Control chemistry/acid/corrosion resistance with dissimilar metals

high durability

Stable under tension

No punching, perforating or stretching operations are used in the weaving process

Corrosion, wear and heat resistance.

Hygienic properties and cleaning power are particularly suitable for the food and pharmaceutical industries.

Cost-effective

Application

Stainless steel wire mesh has been widely used in chemical, petrochemical and oil exploration, transportation, nuclear industry, energy, textile, aerospace, electronics, food, phamaceutical, paper and other industrial sectors, in certain areas or may not become an indispensable substituted metal material. In addition, the sub-mesh stainless steel and decorative and easy to clean and antibacterial properties, in the consumer sector it has been widely used, such as construction and decoration, kitchen utensils,cutlery, metal and other civil.

Hot Searches