- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/UPON

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

5000

-

Marketing Type:

-

Available

-

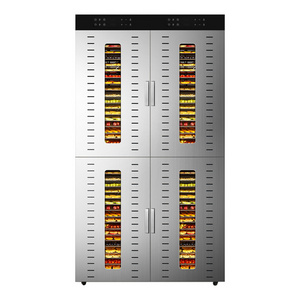

Name:

-

drying equipment

-

Item:

-

Dehydrator Machine

-

Heating source:

-

Electricity Steam Oil Gas

-

Advantage:

-

Low Consumption High Efficiency

-

Raw material:

-

304 Sainless Steel

-

Installation:

-

Engineer Guidance Installation

-

MOQ:

-

1 Set

-

Product Type:

-

chili drying equipment

-

Controller:

-

PLC

-

Dryig process:

-

Continuous Automatic Vegetables Dryer Machine

Quick Details

-

Type:

-

Drying Oven

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Flysun

-

Voltage:

-

380V/UPON

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Accroding to model

-

Weight (KG):

-

5000

-

Marketing Type:

-

Available

-

Name:

-

drying equipment

-

Item:

-

Dehydrator Machine

-

Heating source:

-

Electricity Steam Oil Gas

-

Advantage:

-

Low Consumption High Efficiency

-

Raw material:

-

304 Sainless Steel

-

Installation:

-

Engineer Guidance Installation

-

MOQ:

-

1 Set

-

Product Type:

-

chili drying equipment

-

Controller:

-

PLC

-

Dryig process:

-

Continuous Automatic Vegetables Dryer Machine

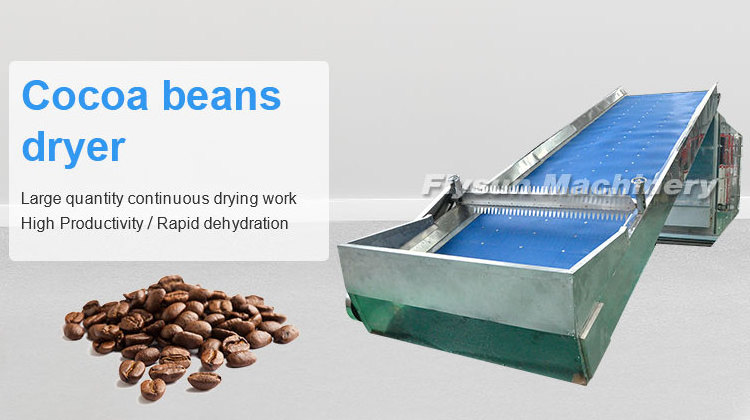

Brief Introduction of vegetable

drying equipment

The potato

drying equipment

are used for drying the high moisture material to a suitable moisture, so that the material can be reached a high efficient use value.

Introduction of vegetable

drying equipment

The vegetable

drying equipment

are used for drying the fruits and vegetables,also work for herbs. The drying is one of the most important step during the drying processing.After drying, the material can be more easy to reserve,or it can be milled by grinding machine to reach higher efficient use value. The vegetable drying system is consists of feeding conveyor, belt dryer host, discharge conveyor, heat exchange furnace, hot air induced draft fan, exhaust fan,control panel. According to variety of vegetable and different water content , we make different drying scheme .

Product Details

Advantage of vegetable

drying equipment

1.Uniform drying effect--The vegetable keep moving on the belt, during this process, both side of the material can fully contact the hot air. So that the drying effect can be uniform.

2.Drying time--Our drying adopt to centrifugal fan with model Y4-73, the flow can achieve flow 54526 m³/hour, the fully hot air greatly shorten the drying time, it can drying chili pepper within 2-4 hours.

3.Adjustable speed--Drying temperature,moisture can be adjusted by the control panel by adjust the mesh belt running speed and air rate.

4.Energy saving--Only small electricity consumption, saving 60% running cost.

5.Various fuel--Dryer machine can use coal, wood, gas, diesel, electricity, can meet different customer requirements.

2.Drying time--Our drying adopt to centrifugal fan with model Y4-73, the flow can achieve flow 54526 m³/hour, the fully hot air greatly shorten the drying time, it can drying chili pepper within 2-4 hours.

3.Adjustable speed--Drying temperature,moisture can be adjusted by the control panel by adjust the mesh belt running speed and air rate.

4.Energy saving--Only small electricity consumption, saving 60% running cost.

5.Various fuel--Dryer machine can use coal, wood, gas, diesel, electricity, can meet different customer requirements.

Technical Parameters

The detailed parameter of vegetable

drying equipment

|

Model(Width*Length)

|

FS1.5-6-4

|

FS2-8-4

|

FS2-9-4

|

FS2-10-4

|

|||||

|

Layers

|

4

|

|

|

|

|||||

|

Drying area(㎡)

|

29

|

45

|

51

|

57

|

|||||

|

Spread thickness of material(mm)

|

50-200

|

|

|

|

|||||

|

Working temperature(℃)

|

0-120

|

|

|

|

|||||

|

Working time(hour)

|

24

|

|

|

|

|||||

|

Capacity(t/h)

|

100-150kg/h

|

200kg/h

|

250kg/h

|

300kg/h

|

|||||

|

heat exchange furnace(M)

|

3.2*1*2.7

|

3.9*1.26*3

|

3.9*1.26*3

|

4.7*1.5*3

|

|||||

|

Induced draft fan(kw)

|

11

|

15

|

15

|

22

|

|||||

|

Exhaust fan(kw)

|

1.5

|

|

2.2

|

|

|||||

|

Feeding conveyor(kw)

|

1.5

|

2.2

|

2.2

|

2.2

|

|||||

|

Discharge conveyor(kw)

|

0.55

|

|

|

|

|||||

|

Total power(kw)

|

14.55

|

19.25

|

19.95

|

26.95

|

|||||

|

LP gas consumption

(90 degree fanrenheit) |

20m³/H

|

25m³/H

|

28m³/H

|

30m³/H

|

|||||

|

Place requirement

(W*L*H)M |

4.5*14*2.7

|

5*19*2.8

|

4.5*20*2.8

|

5.5*21*2.8

|

|||||

Customer Cases

Customer Cases of vegetable

drying equipment

1.Pakistan customer use vegetable

drying equipment

for capacity 3T/day;

2.America customer use vegetable

drying equipment

for capacity 3.5T/day;

3.India customer use vegetable

drying equipment

for capacity 10T/day;

.......

Customer Visit

Hot Searches