- Product Details

- {{item.text}}

Quick Details

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bogong Mchinery

-

Voltage:

-

AC380V/50HZ or AC220V/50HZ

-

Dimension(L*W*H):

-

1300*5000*300mm, 1300x5000x300mm

-

Weight (KG):

-

100

-

Application:

-

wood mdf acrylic aluminium stainless steel

-

Spindle:

-

0.8 1.2 kw Water Cooling Spindle/ 4.5kw air cooling spindle

-

Transmission:

-

Taiwan PMI/ABBA Linear Square Rail and TBI ball screw

-

Working area:

-

600*900 1300*500 1200*2400 1200*1200

-

Software:

-

Artcam/Type3/Artcut/Ncstudio

-

Spindle power:

-

1.5kw/2.2kw/3kw/4.5kw

-

Spindle speed:

-

24000rpm/min

-

Motor:

-

Stepper Motor

-

Weight:

-

1800kg

-

Power:

-

6KW

Quick Details

-

Working Table Size(mm):

-

1300×2500

-

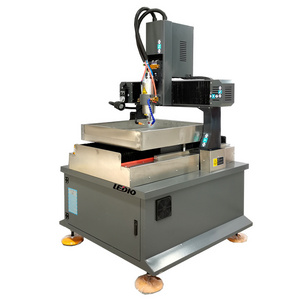

Machine Type:

-

CNC Router

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

1300 mm

-

Travel (Y Axis)(mm):

-

2500 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bogong Mchinery

-

Voltage:

-

AC380V/50HZ or AC220V/50HZ

-

Dimension(L*W*H):

-

1300*5000*300mm, 1300x5000x300mm

-

Weight (KG):

-

100

-

Application:

-

wood mdf acrylic aluminium stainless steel

-

Spindle:

-

0.8 1.2 kw Water Cooling Spindle/ 4.5kw air cooling spindle

-

Transmission:

-

Taiwan PMI/ABBA Linear Square Rail and TBI ball screw

-

Working area:

-

600*900 1300*500 1200*2400 1200*1200

-

Software:

-

Artcam/Type3/Artcut/Ncstudio

-

Spindle power:

-

1.5kw/2.2kw/3kw/4.5kw

-

Spindle speed:

-

24000rpm/min

-

Motor:

-

Stepper Motor

-

Weight:

-

1800kg

-

Power:

-

6KW

|

Rack and pinion transmission for large stroke, high precision, large torque transmission.CNC machine tool |

|

|

w

ell known water cooling spindle,high concentricityand verticality,high ,precision,long life

|

|

|

Imported high-precision ball screw

which moving smoothly, to ensure the machine's high precision.

|

|

|

Electric Cabinet

All the electrical components are housed and wired in a mobile, double door electrical enclosure. This allows for easy access and service when needed. Every wire is tagged so that when service is required, the customer can easily navigate the cabinet. |

|

|

Double bags dust collector to clean dust in time,Keep the air clean |

Woodworking industry:

three-dimensional wave board processing, cabinet doors, solid wood doors, wooden doors, paint doors, screens, window processing technology, shoe polisher, game cabinets and panels, Mahjong table, computer assisted processing tables and panel furniture products.

Advertising industry:

advertising signs, sign making, acrylic cutting, plastic molding, a variety of advertising and decorative products.

Mold industry:

carving copper, aluminum, iron and other metal molds, as well as artificial marble, sand, plastic board, PVC pipe, wood and other non-metallic mold

Other industries:

various large relief carving, shadow carving, widely used in craft gift industry.

Special Feature for Wood Engraving Machine

1) Using Professional Dust Collecting System (for Cutting Wood) and Vacuum System (for absorbing objects)

2)Advanced digit-control system, handle operation and large liquid crystal display brings out more convenient operation, simpler maintenance and more human nature on the design of the machine

3) The three axes use linearity square guide rail and drive which could meet different cutting demand and has high cutting precision.

4) Unique intelligent calculation fully develops the potential of the electric machinery and leads to high speed processing, the synchronization of curves and straight lines, smoother curves and race speed at 12m/min.

5) Large internal memory capacity of 32M is able to store 30 processing files simultaneously and open and process any of them

6) This model uses domestic-leading PCI controlling system. It uses imported square shape guide rail and the transmission is steady. It adopt high-precision level gear transmission, the maximum speed can reach 30m/m. It can engrave the graph of 1.5*1.5mm clearly.

Technical Parameters:

|

Model |

BG -1325 |

|

X / Y Working size |

1300*2500mm |

|

Z feed Height |

200mm |

|

Table Surface |

Vacuum or T-slot Combined |

|

X / Y Structure |

Rack and Pinion Drive Hiwin Linear Square Guide Rail |

|

Z Structure |

Hiwin Linear Square Guide Rail and Ball Screw |

|

Max. Power Consumption |

(Without spindle) 2.0Kw |

|

Max. Rapid Travel Rate |

33000mm/min |

|

Max. Working Speed |

25000mm/min |

|

Spindle Power |

5.5 KW air cooling spindle |

|

Spindle Speed |

0-24000RPM /min |

|

Drive Motors |

servo motor and drivers |

|

Working Voltage |

AC220V/50/60Hz 380V |

|

Command Language |

G code |

|

Control System |

SYNTEC |

|

X / Y / Z reposition Accuracy |

±0.01mm |

|

X / Y Resolution |

<0.01mm |

|

Software |

Mach 3 control / NC-Studio or DSP controller |

|

Running Temperature |

0 degree - 45 degree |

|

Relative Humidity |

30% - 75% |

1. Beforesale: We will try to know your requirement about our cnc router specificationand what kind of work you will do.Then we will offer our best solution for your requirement. Then it can confirm each customer can get their real needed machine

2.During production: We will send photos of machines during making. So customers can know more details about the procession of making their machines and give them suggestions.

3. Before shipping: We will take delivery photo and confirm the specification of order to avoid the mistake. Machine will be adjusted before it is delivered.

4.After shipping: We will check when the machine arrive your sea port and approximate date of arrival. So customers can know when it will arrive and make enough preparation.

5.After arrival: We will confirm with customers if machine is in good condition and see if any spare parts missing

6.About teaching: Here are some manual and video about how to use machine, if you have questin about it, we will have professional technicist to help you install and teach how to use through skype, calling , video or eamil.

7. About warranty: We offer 1 year warranty, replace parts for free, no human reason.

8. Service in longterm: We hope every customer can use our machine easily and have a fun of it. If you haveany problems of machine in 2 or 3 , 5 years, you can contact us. We will always here waiting for you.

Q1: I knew nothing about this machine, what kind of machine i should choose?

A1: Very easy to choose. Just tell us what you want to do by using CNC router, then let us give you perfect solutions and suggestions.

Q2: When I got this machine, but I don’t know how to use it. What should I do?

A2: We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

Q3: If some problems happen to this machine during warranty period, what should I do?

A3: We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. So any doubts, just let us know, we will give you solutions.

Q4: Before sending me an inquiry on our cnc router, it is better for you to provide me the following information

A4: 1)Your metal or non-metal material size. Because in our factory, we have different models according to working area.

2)Your materials:Metal/Acrylic/plywood/MDF?

3)You want to engrave or cut?