- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIXER

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

According to model

-

Power (kW):

-

75

-

Weight:

-

3500 KG

-

Automatic Grade:

-

automatic

-

Machine color:

-

as your demands

-

Power(W):

-

55-75KW

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE,ISO

-

Marketing Type:

-

New Product 2020

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

40:1

-

Screw diameter (mm):

-

62.4 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIXER

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

According to model

-

Power (kW):

-

75

-

Weight:

-

3500 KG

-

Automatic Grade:

-

automatic

-

Machine color:

-

as your demands

-

Power(W):

-

55-75KW

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE,ISO

-

Marketing Type:

-

New Product 2020

Product Description

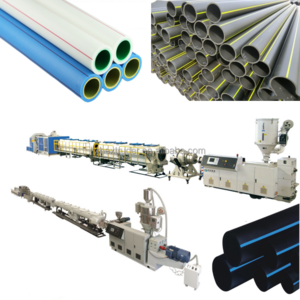

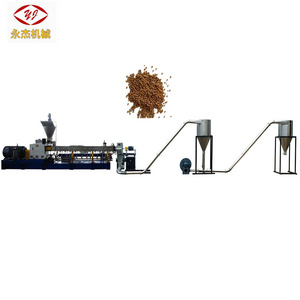

compounding twin screw extruder machine,extruder silicone machine,polycarbonate extruder

Application of twin screw extruder for the materials in details as follows:

PE/PP/ABS/PC/EVA+CaCO3/Talc/TiO2;

PC+ABS/PA+EPDM/PBT+PET/PP+NBR;

PE/PP/ABS/PC/EVA/PET;

ANTI RETARDANT MASTERBATCH;

DE-COMPOSING MASTERBATCH;

ANTISTATIC MASTERBATCH;

ANTIBACTERIAL MASTERBATCH;

PA/PP/PC/ABS/PBTPOM+GLASS FIBER;

TPR/TPE/TPV/TPU;

PE/PP/EVA/PVC/XLPE;

PA/PU/POM/PMMA/PC;

CPP/CPE/SBS/EPDM/SEBS,FPM,/BR;

COATING MATERIALS

Electric control system for parallet co rotating twin screw extruder:

Common instruments control:

1) Temperature controller,inverter, breaker, contactor, SSR and

control buttons are of foreign famous brand asper customer's option.

2)The PLC control system is adopted to optimize the operations circuit.

3)Control unit like solenoid valve are of Euopean brand.

4)The whole extrusion line has driving & interlock pretect, and troulble &interlock proctec systems.

5)The simulation display is equipped, which can show the running state clearly

and dynamically.

HIMI control:

1) Adopt the improted brand such as Omron and Siements with characters of simpliefied

Circuit and safety.

2) Start/Stop of all the motors can be operated on the touch-screen.

3)The operations status of the line can be displayed dynamically.

4) Dynamic cruve display, input and save of parameters such as rmp, electric current, temp

control and pressure.

5) Presenting the detailed record of warning, document retrieval, and maintenance.

6) Reserve the interface of the bus line, to realize the collections, analyze, save and print data.

Specification

|

SJSL

series co-rotating twin screw extruder

|

||||||

|

Model

|

Diameter (mm)

|

Screw speed

(RPM)

|

L/D

|

Motor (KW)

|

Torgue ( N.M)

|

Capacity(KG/H)

|

|

SJSL-20

|

22

|

600

|

32-60

|

3

|

35

|

1-5

|

|

SJSL-

35

|

35.6

|

600

|

32-60

|

15-18.5

|

115

|

10-45

|

|

SJSL

-50

|

50.5

|

500-600

|

32-60

|

37-45

|

405

|

100-200

|

|

SJSL

-60

|

59.5

|

400-500

|

32-60

|

55-75

|

675

|

200-300

|

|

SJSL

-60B

|

59.5

|

500-600

|

32-60

|

75-90

|

675

|

250-600

|

|

SJSL

-65

|

62.4

|

400-500

|

32-60

|

55-75

|

675

|

200-300

|

|

SJSL

-65B

|

62.4

|

500-600

|

32-60

|

75-90

|

1200

|

250-600

|

|

SJSL

-75

|

71

|

400-500

|

32-60

|

90-110

|

1005

|

300-500

|

|

SJSL

-75B

|

71

|

500-600

|

32-60

|

110-162

|

1875

|

750-950

|

|

SJSL

-95

|

91

|

400

|

32-60

|

220

|

2250

|

750-1250

|

|

MT-95

|

91

|

500

|

32-60

|

500

|

3740

|

1000-1250

|

|

|

|

|

|

|

|

|

|

Tandem extruder (Twin Screw and Single Screw Extruder Unit)

|

||||||

|

Model

|

Twin Screw Diameter(mm) |

Single Screw Diameter (mm.)

|

Screw Speed (rpm)

|

L/D

|

Motor (kw)

|

Capacity(Kg/h)

|

|

SJSL

50-100

|

50.5 | 100 |

500

|

32-40

|

37

|

150-300

|

|

85

|

7-15

|

22

|

||||

|

SJSL

65-150

|

62.4 | 150 |

400-500

|

32-40

|

55-75

|

400-600

|

|

85

|

7-15

|

37

|

||||

|

SJSL

75-180

|

71 | 180 |

400-500

|

32-40

|

90-110

|

600-800

|

|

85

|

7-15

|

75

|

||||

|

SJSL

95-200

|

MT95

|

91

|

400-500

|

32-40

|

132-160

|

800-1200

|

Packaging & Shipping

Hot Searches