- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

Lanyu

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

5100*1650*2760mm

-

Power (kW):

-

55

-

Weight:

-

4800 KG

-

Motor::

-

SIEMENS

-

Inverter::

-

ABB

-

Temperature-controlled::

-

Japanese OMORN

-

Screw&barrel::

-

30CrMoAlA

-

Heating way::

-

Foundry Aluminum Heater

-

Gearbox::

-

DELING

-

Contactor::

-

SIEMENS

-

Automatic Grade::

-

Fully Automatic

-

Power(W)::

-

60-300kw

-

Service:

-

on line

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

80mm,156mm

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

China

-

Brand Name:

-

Lanyu

-

Voltage:

-

380V , 50Hz or Customized

-

Dimension(L*W*H):

-

5100*1650*2760mm

-

Power (kW):

-

55

-

Weight:

-

4800 KG

-

Motor::

-

SIEMENS

-

Inverter::

-

ABB

-

Temperature-controlled::

-

Japanese OMORN

-

Screw&barrel::

-

30CrMoAlA

-

Heating way::

-

Foundry Aluminum Heater

-

Gearbox::

-

DELING

-

Contactor::

-

SIEMENS

-

Automatic Grade::

-

Fully Automatic

-

Power(W)::

-

60-300kw

-

Service:

-

on line

Product Description

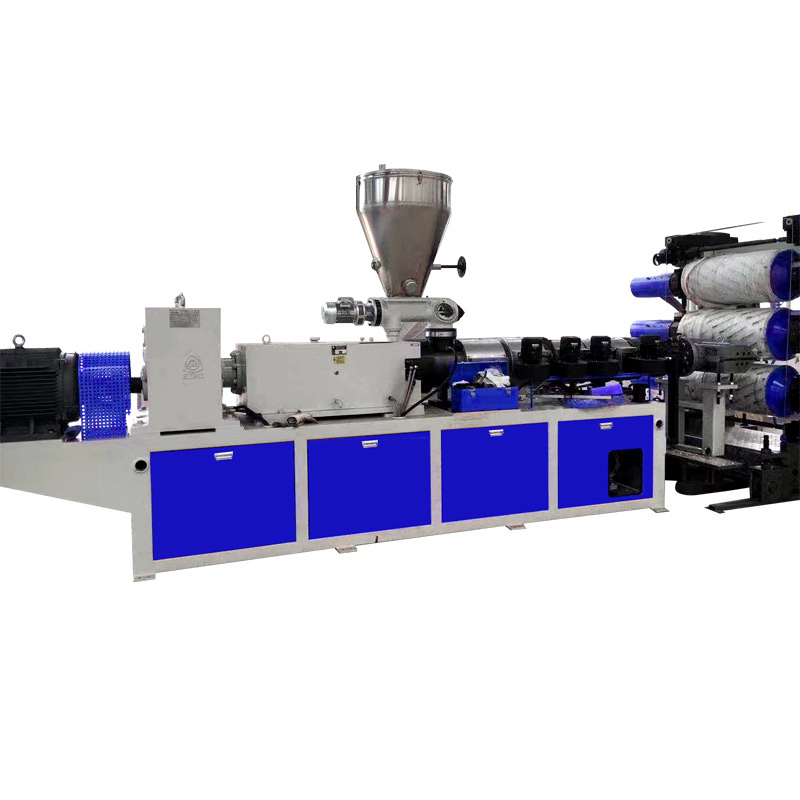

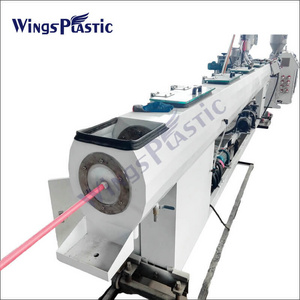

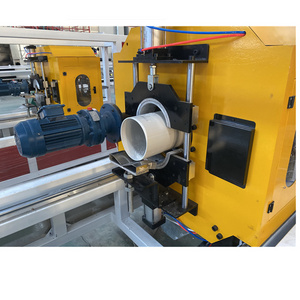

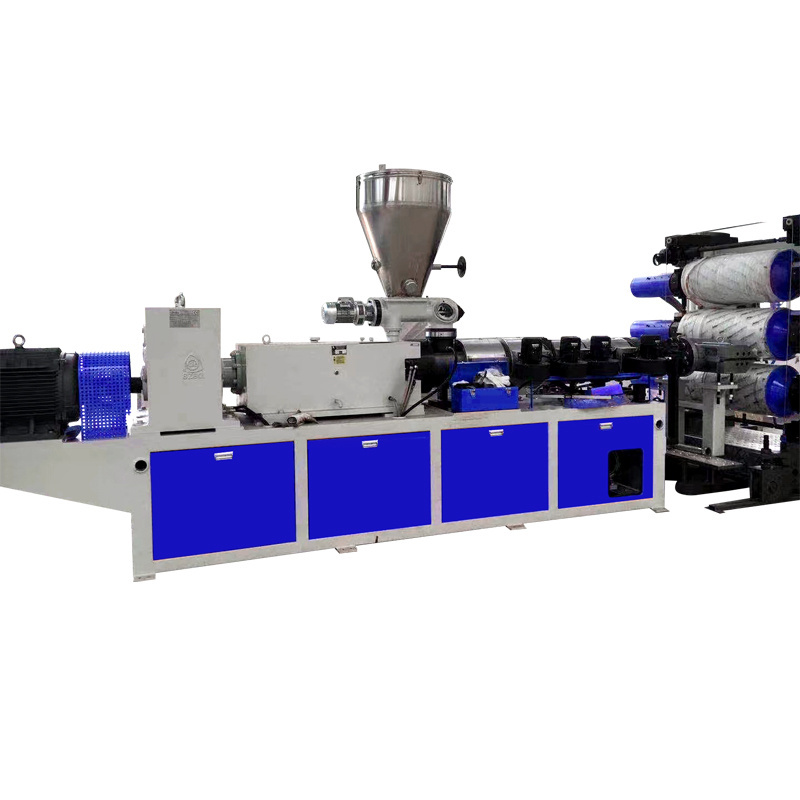

1. a) Extrusion system: (screw & barrel)

Screw & Barrel Made in China Lanyu, One of largest screw manufacturer in Asia

Screw diameter: ¢80mm, 156 mm

Output: 250-450kg/h

Through the conical meshing method, the counter-rotation is carried out, the speed: 1 ~ 34.7 r/min.

Screw material: high-quality alloy steel - 38CrMoAlA, after high-temperature nitriding treatment, nitrided layer depth: 0.5~0.7mm,surface hardness: HV740~940 screw cold edge slotted alloy (using bimetallic treatment to improve the service life of the screw)

Barrel material: high-quality alloy steel - 38CrMoAlA, after high-temperature nitriding treatment, nitrided layer depth:

0.6~0.7mm, surface hardness ≥ HV940 (extrusion section adopts bimetallic treatment to improve the service life of the barrel)

Barrel temperature control system:

Heating zone: cast aluminum heating coil + stainless steel surface housing + cooling fan

Cooling device: The fan uses air as the medium to provide precise temperature control

Number of heating zones: 5, total heating power 32kw. Temperature range 50~300℃

Cooling fan power: 4 × 0.75kw/set

The external temperature control of the machine barrel adopts the cooling fan for strong cooling to control the temperature

Screw & Barrel Quality Assurance: Advanced processing and testing equipment, strict heat treatment control process, provide test block and test report.

1. b) Quantitative feeding system:

1.21 stainless steel feeding hopper. Double feeding system

1.22 Quantitative feeding device

1.23 Feeding motor power: 1.1kw three-phase asynchronous motor, connected with a micro-swing needle transmission, motor speed range 10 ~ 1500 r/min. Feeding screw speed range: 1 ~ 50 r/min.

1.2.4 Feeding device speed regulation, controlled by ABB AC drive

1.2.5 Contains one spring loading machine

1. d) Transmission reduction system

1.41 adopts high torque reducer.

1.42 Water cooling cooling device.

1.43 gear box gear material: 20CrMoTi, gear reduction, using hard tooth surface helical tooth surface combination, gear

carburizing and grinding treatment.

1.44 Adopt German technology, long service life, low noise and low heat.

1.45 horizontal gear box, the main motor is connected with the gear box through a coupling.

1.46 Distribution box: Transform from single-shaft torque output to double-shaft torque output through super bevel gears

1. e) Main motor system

1.51 Asynchronous motors

1.52 Main motor power: 55 kw , 380V, 50Hz

1.53 Main motor speed regulation mode: controlled by ABB frequency conversion speed regulator

1. f) Dimensions and weight of the extruder

1.61 Dimensions: 5100×1650×2760 mm

1.62 Center height: 1100mm

1.63 Machine weight: 4800Kg

1. g) Electrical control system

1.71 Optimally designed electrical control cabinet

1.72 AC frequency converter Swiss ABB company

1.73 Schneider AC contactor

1.74 Emergency stop device and alarm system

1.75 total of 20 heating zones

1. h) Alarm system detection range:

1.8 - Overcurrent protection and alarm function

- Automatic stop alarm function for screw loosening and falling off

- Fuel shortage alarm for constant temperature fuel tank

Specification

|

item

|

value

|

|

Application

|

PIPE

|

|

Screw Design

|

Double-screw

|

|

|

Counter-rotating conical Twin-screw

|

|

Screw Material

|

38CrMoALA

|

|

Screw diameter (mm)

|

80mm,156mm

|

|

Screw L/D Ratio

|

33:1

|

|

Screw Speed (rpm)

|

50rpm

|

|

Showroom Location

|

None

|

|

Place of Origin

|

China

|

|

Brand Name

|

Lanyu

|

|

Voltage

|

380V , 50Hz or Customized

|

|

Dimension(L*W*H)

|

5100*1650*2760mm

|

|

Power (kW)

|

55

|

|

Weight

|

4800KG

|

|

Warranty

|

1 Year Warranty

|

|

Key Selling Points

|

High Productivity

|

|

Applicable Industries

|

Manufacturing Plant

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Motor

|

|

Machinery Test Report

|

Provided

|

|

Motor:

|

SIEMENS

|

|

Inverter:

|

ABB

|

|

Temperature-controlled:

|

Japanese OMORN

|

|

Screw&barrel:

|

38CrMoAlA

|

|

Heating way:

|

Foundry Aluminum Heater

|

|

Gearbox:

|

DELING

|

|

Contactor:

|

SIEMENS

|

|

Automatic Grade:

|

Fully Automatic

|

|

Power(W):

|

60-300kw

|

|

Service

|

on line

|

Packing & Delivery

pallet

Other Hotsale Products

FAQ

1. who are we?

We are based in Hebei, China, start from 2015,sell to Eastern Europe(20.00%),Domestic Market(15.00%),Western Europe(15.00%),South America(15.00%),North America(10.00%),Southeast Asia(7.00%),Eastern Asia(5.00%),Mid East(5.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cooling tower fill,fiberglass duct rodder,frp manhole cover,tube settler,frp grating

4. why should you buy from us not from other suppliers?

Hebei Lanyu Rubber & Plastic Co.Ltd is one of the leading manufacturers and suppliers of MBBR media and other water treatment media. Our products are sold to over 30 countries. Strong sales and service team, advanced production equipment.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash;

Language Spoken:English,Chinese

We are based in Hebei, China, start from 2015,sell to Eastern Europe(20.00%),Domestic Market(15.00%),Western Europe(15.00%),South America(15.00%),North America(10.00%),Southeast Asia(7.00%),Eastern Asia(5.00%),Mid East(5.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cooling tower fill,fiberglass duct rodder,frp manhole cover,tube settler,frp grating

4. why should you buy from us not from other suppliers?

Hebei Lanyu Rubber & Plastic Co.Ltd is one of the leading manufacturers and suppliers of MBBR media and other water treatment media. Our products are sold to over 30 countries. Strong sales and service team, advanced production equipment.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash;

Language Spoken:English,Chinese

Contact

Hot Searches