- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

45KW

-

Weight:

-

8000 KG

-

Dimension(L*W*H):

-

2300*1650*2100mm

-

Year:

-

2022

-

Product Name:

-

Americhi corn chips making machine Cereal corn flakes sereal mesin pem

-

After-sales Service:

-

Engineers available to service machinery overseas, Field installation

-

Heating method:

-

Electricity, steam, gas, Diesel Oil

-

Machine material:

-

stainless steel

-

Motor brand:

-

Siemens, ABB or customized

-

Capacity:

-

150---500kg/h

-

Shapes:

-

Used to produce snacks, cereals by adjusting the moulds from extruder

-

Raw materials:

-

Corn flour

-

After Warranty Service:

-

Online support, Spare parts, Video technical support

-

Local Service Location:

-

India, Turkey, etc.

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMC

-

Voltage:

-

220V/380V

-

Power:

-

45KW

-

Weight:

-

8000 KG

-

Dimension(L*W*H):

-

2300*1650*2100mm

-

Year:

-

2022

-

Product Name:

-

Americhi corn chips making machine Cereal corn flakes sereal mesin pem

-

After-sales Service:

-

Engineers available to service machinery overseas, Field installation

-

Heating method:

-

Electricity, steam, gas, Diesel Oil

-

Machine material:

-

stainless steel

-

Motor brand:

-

Siemens, ABB or customized

-

Capacity:

-

150---500kg/h

-

Shapes:

-

Used to produce snacks, cereals by adjusting the moulds from extruder

-

Raw materials:

-

Corn flour

-

After Warranty Service:

-

Online support, Spare parts, Video technical support

-

Local Service Location:

-

India, Turkey, etc.

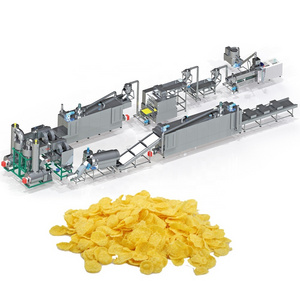

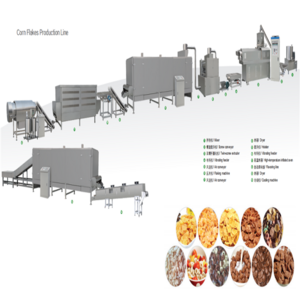

A. Corn Flakes / Breakfast Cereal Machine Products show:

B. Why should you choose us?

1. High productivity - Up to 1500kg/h

|

The output range of our machine's products varies:

80-120kg/h; 200-260kg/h; 260-300kg/h; 400-500kg/h; 600-800kg/h; 1000-1500kg/h |

2. Longer screw length - Up to 2100mm

|

The screw diameter: 75mm Screw length: 2290mm |

|

3. Good waterproof - Water tight mild steel enclosure

|

|

The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating, water cooling on barrel. |

4. High digitization - Comprehensive digital visual control panel

|

Digital indicator of extruder motor load; Digital indicator of feed screw speed; Digital indicator/controller for each temperature zone in barrel; ...

|

5. More wear-resistant - More wear resistant bimetal barrel

|

|

Total 7 Extruder barrel (Bimetallic barrel) with replaceable wear resistant liners. |

6. Self-cleaning function - The screws is self-cleaning

|

a. A corotating twin screw extruder with a self-wiping screw profile; b. Comparison between the results obtained from finite volume and finite element approaches, the latter being shown as points, for a corotating, self-wiping, twin screw extruder

|

7. Easy to disassemble - Shaft couplings permit easy removal of extruder shafts

|

|

Shaft couplings permit easy removal of extruder shafts for maintenance or lengthening or shortening of extruder barrel. |

8. High quality - Screw material: 38CrMoAL (nitrided); Hardness: HRC55-60

|

We only use first-class steel and check every production procedure to ensure every demension is produced precisely.

|

|

9. Super torque - Ultra Torque Gearbox

|

|

|

10. High rust resistance - Stainless steel product contact surfaces SUS 304

|

1. Environmental protection and hygiene; 2. Wear resistance; 3. High temperature and low temperature resistance; 4. Excellent thermal expansion performance and thermal insulation performance; 5. Corrosion resistance. |

11. High efficiency - High water cooling efficiency

|

|

Extra cooling system in lubrication oil tank ensure cooling oil at low temperature, the water cooling efficiency is low. |

12. Longer life - Screw life time: >7000hours

|

more durable;

higher cost performance; greater capacity. |

13. Quality assurance - Ten years for machine case

| You only need to replace the core components to flexibly transform the production line, without worrying about the quality of the machine body. |

14. Automatic control - Automatic temperature control

|

Improve work efficiency;

Increase production capacity per unit time; No need to take up too many human resources; Save labor costs; Save the cost of raw materials; Improve business efficiency |

Raw materials:

A

dopts

corn flour as raw materials.

Products: This line can be used to produce snacks, cereals by adjusting the moulds from extruder.

Capacity: 150kg/h, 240kg/h, 500kg/h

|

Model |

Installed power |

Output |

|

AMC 65 |

81.5kw |

100-150kg/h |

|

AMC 70 |

115.0kw |

200-240kg/h |

|

AMC 300 |

63.0kw |

200-300kg/h |

|

AMC 500 |

99.0kw |

400-500kg/h |

|

AMC 800 |

128.0kw |

600-800kg/h |

|

AMC 1500 |

196.0kw |

1000-1500kg/h |