- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

10 years

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kingmetal

-

Material:

-

Carbon Steel

-

Keyword:

-

large diameter fitting cap

-

Technical:

-

press/forged/push/casting

-

Standard:

-

GB/ASTM/DIN/EN/ISO/GOST

-

Surface treatment:

-

Sand Blasting/galvanized/black painting

-

Size:

-

up to 72 inch or ODM

Quick Details

-

Technics:

-

Casting/push/forged

-

Shape:

-

Equal

-

Head Code:

-

Square

-

Warranty:

-

10 years

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kingmetal

-

Material:

-

Carbon Steel

-

Keyword:

-

large diameter fitting cap

-

Technical:

-

press/forged/push/casting

-

Standard:

-

GB/ASTM/DIN/EN/ISO/GOST

-

Surface treatment:

-

Sand Blasting/galvanized/black painting

-

Size:

-

up to 72 inch or ODM

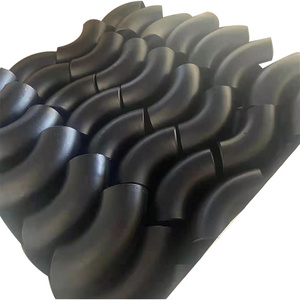

ASME B16.9 A234 WPB Large Diameter 72 inch Cap of Pipe Fitting

A pipe cap is a pipe fitting welded to the end of the pipe or threaded to cover the pipe. Used to close the pipe, the function is the same as the pipe plug. The pipe cap is also called a plug, a cap, a pipe cover, and a stuffy head. Used to close the pipe, the function is the same as the pipe plug, but the pipe cap can be directly rotated on the pipe, no other pipe fittings. It is generally used at the end sampling port of the pipe. After the sampling is completed, the pipe cap should be screwed on. The other is that under special circumstances, after the pipe cap is removed, the pipe can be connected with the wire mouth, and the material can be taken or pumped continuously. Pipe cap in the case of low pressure, easy to disassemble and repair, high pressure generally do not use the cap. The cap comprises a convex cap, a conical shell, a variable diameter section, a flat cover and a tight port. The pipe cap is similar to the head shape, the material is more stainless steel, the pipe cap size is smaller, can be forged; the head size is larger, generally pressed with steel plate, the pipe cap is generally used at the end of the pipe, Head for upper and lower container equipment (vertical equipment) or left and right end (horizontal equipment). Convex tube cap includes: hemispherical tube cap, elliptical tube cap, disc tube cap and ball crown tube cap. From the point of view of force, the hemispherical tube cap is not good, but from the point of view of manufacturing difficulty, it is easy to manufacture.

| specifications | Cap |

| Pipe End Cap Pipe Fittings size |

Seamless Butt Weld Fittings: 1/2" - 24"

Welded Butt Weld Fittings: 2" - 72" or ODM |

| Pipe Cap Fittings Dimensions | ASME/ANSI B16.9, MSS-SP-43 |

| Bw Pipe Cap Thickness |

SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS |

| Cap Bw Sch 80 Types | Seamless / ERW / Welded |

| Bw Cap Type | DN15-DN1200 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Pipe Cap Fittings Fittings |

Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D.

Standard: ASME B16.9,ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Cap Bw Sch 80 Fittings Test Certificates |

EN 10204/3.1B

Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Application |

Fittings To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc ASME B16.9 Schedule 10 Pipe Cap are an economical alternative for lower-pressure applications. ANSI B16.9 Schedule 40 Pipe Cap have a thicker wall for higher-pressure applications. |