We have Automatic Rubber System ability, the system include

the internal mixer, mixing mill, carbon black material storage,

automatic weighing and dosing system, the material recipe design room, constant temperature rubber compoud storage room.

Besides,

the precise pre-forming machine and rotating cooling coveyor

for make rubber cut into granules shape.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

pad

-

Material:

-

Natural rubber or Neoprene Rubber

-

Product name:

-

Vibration Isolation Pads

-

Hardness:

-

20~90 ShoreA

-

MOQ:

-

500pcs

-

Sample:

-

Samples Freely

-

Design:

-

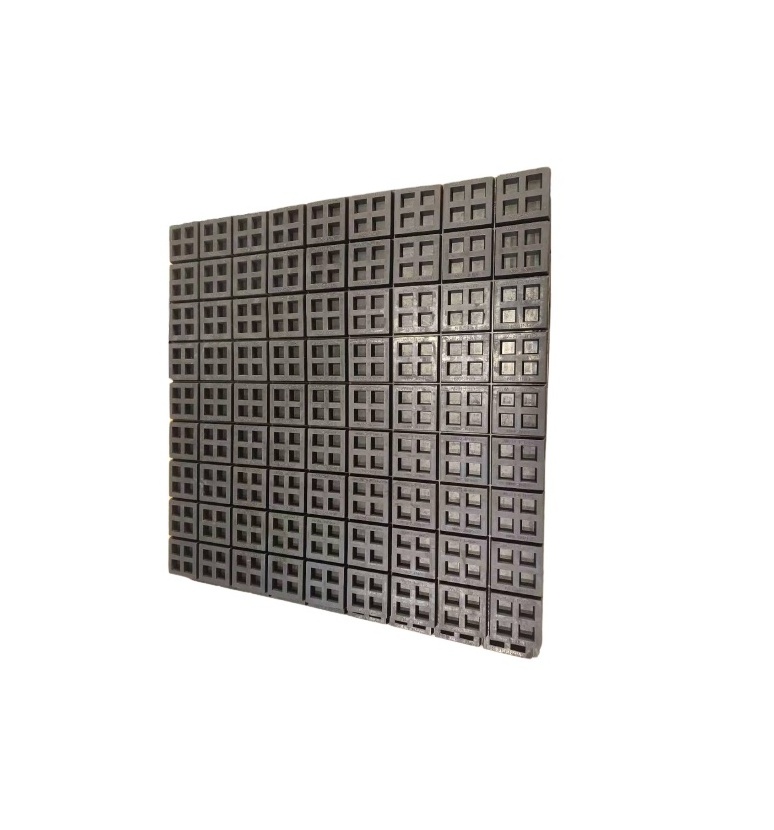

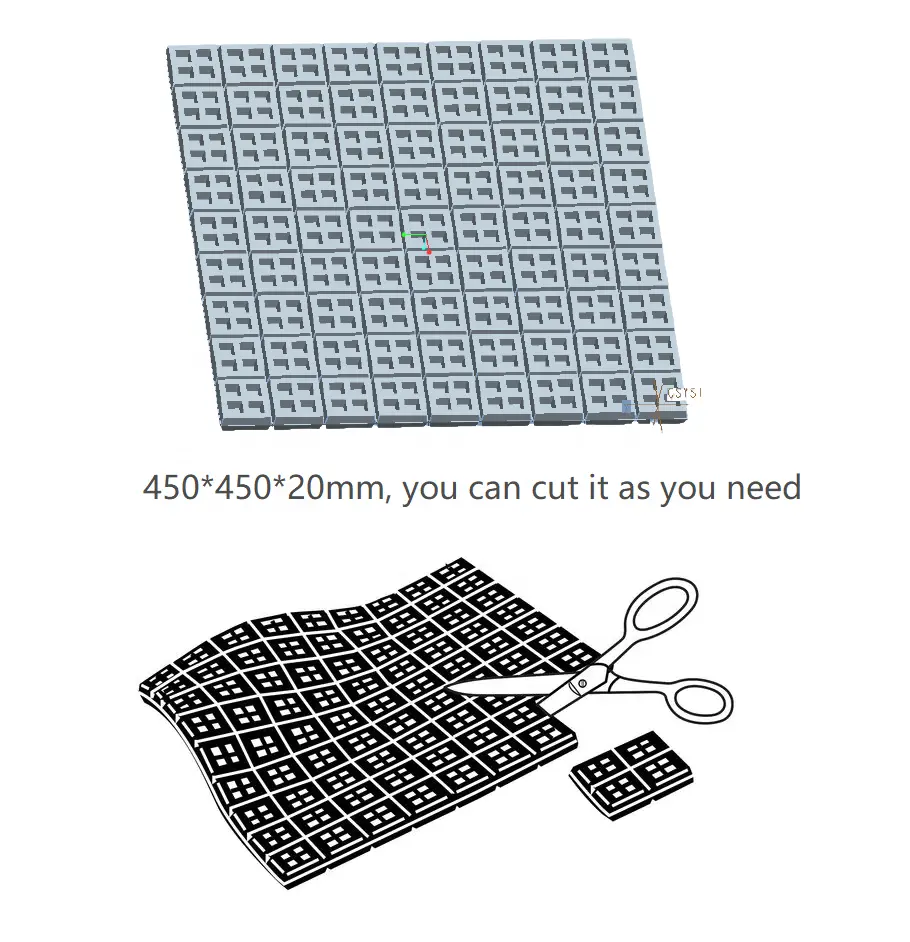

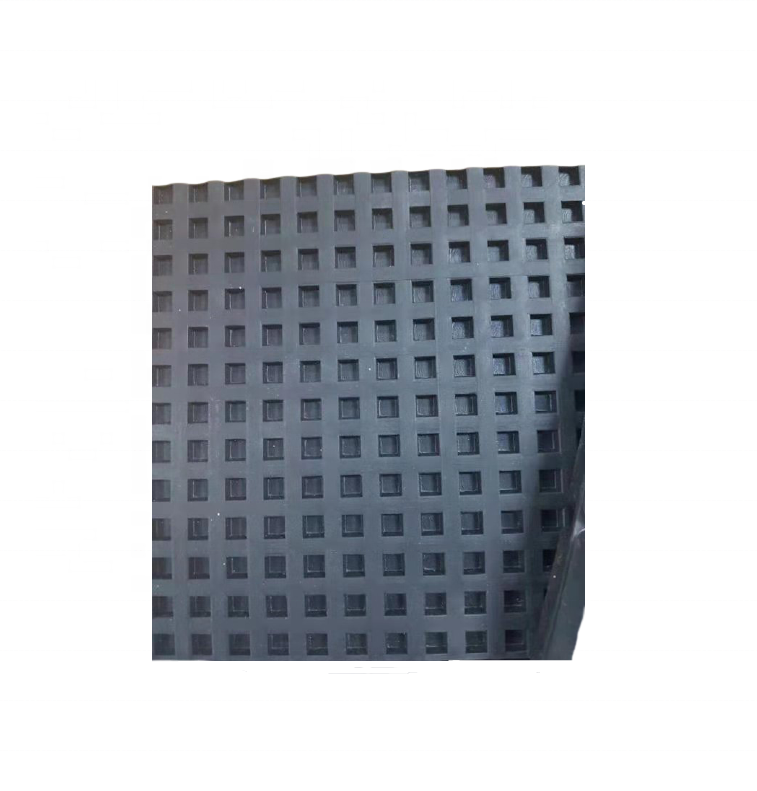

waffle pattern

-

Usage:

-

for machine, HVAC, Air Compressor, Washer and Dryer

-

Use:

-

VIBRATION PAD

-

Weight:

-

0.36kg

-

Rated Capacity:

-

900 kg.f

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

customsized

-

Model Number:

-

pad

-

Material:

-

Natural rubber or Neoprene Rubber

-

Product name:

-

Vibration Isolation Pads

-

Hardness:

-

20~90 ShoreA

-

MOQ:

-

500pcs

-

Sample:

-

Samples Freely

-

Design:

-

waffle pattern

-

Usage:

-

for machine, HVAC, Air Compressor, Washer and Dryer

-

Use:

-

VIBRATION PAD

-

Weight:

-

0.36kg

-

Rated Capacity:

-

900 kg.f

Product Description

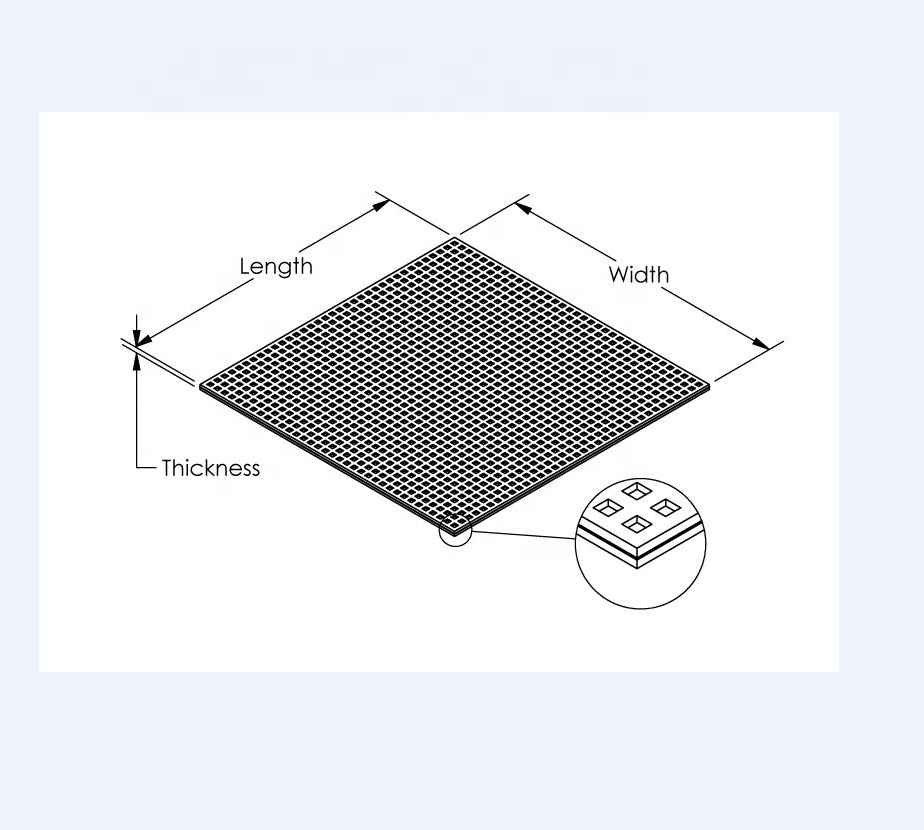

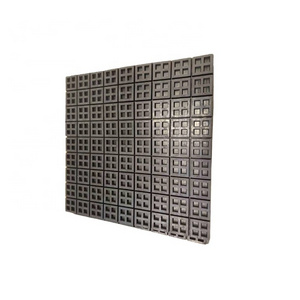

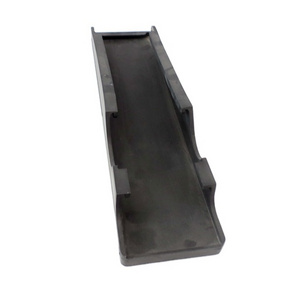

A Vibration Isolation Pad is a high-grade neoprene or rubber isolation medium which can efficiently and economically control structure-born noise and resonant vibration. Vibration Isolation pads can be used to reduce noise, high frequency vibration and impact from machinery. The most common applications have these pads placed under machinery, grinders, compressors, metal panel enclosures or other common sources of high intensity noise levels for vibration and shock control. These vibration control pads are available in various thickness, size and weight rating to meet an array of needs.

* The 18″ x 18″ waffle pattern pads offer a modular design comprised of 2″ x 2″ squares. These squares separate easily when cut to provide evenly distribution to make a smaller pad. The waffle pattern is excellent at preventing slippage.

* The 18″ x 18″ waffle pattern pads offer a modular design comprised of 2″ x 2″ squares. These squares separate easily when cut to provide evenly distribution to make a smaller pad. The waffle pattern is excellent at preventing slippage.

APPLICATIONS:

Chillers, Compressors, HVAC units, Vent Sets, Pumps Motor Generators, Transformers, Diesel Generators, Punch Presses, Lathes, Saws, Power Presses, Drill Presses, floating floors and other structures.

FEATURES:

* Reduce structure borne sound

* Isolate machinery

* Reduce vibration transfer

Chillers, Compressors, HVAC units, Vent Sets, Pumps Motor Generators, Transformers, Diesel Generators, Punch Presses, Lathes, Saws, Power Presses, Drill Presses, floating floors and other structures.

FEATURES:

* Reduce structure borne sound

* Isolate machinery

* Reduce vibration transfer

|

Product Name

|

Vibration Isolation Pads

|

Size

|

6 * 6 * 3/4 inch, 4 * 4* 3/4 inch

|

|

Material

|

rubber

|

Hardness

|

As customer's requirements

|

|

Colour

|

As customer's requirements

|

Place

|

Made in China

|

Related Products

Certificate

IATF 16949 : 2016

JAC Certificate

IATF 16949 : 2016 English

Company Introduction

Wuhu Coi Rubber Products Co.,Ltd

is a

manufacture factory

that produce good & high quality

rubber and plastic products

used for the

car and truck

, also some industries and home appliance areas, starting from 1970. The company provides the

customized products and OEM parts

. The factory own the high technology, well-processing equipments, modern production and a complete quality management system, to realize mass production. We export the products to USA, EUROPE, Japan and some other countries.

Our Services & Strength

Our factory has the

Rubber mixing machines system

, we can mix the rubber, don't need to purchase the rubber material from others. Besides, we have

52 sets rubber vulcanization machines and 10 sets plastic injection machines

, everyday the machine can produce many products to meet the customer's requirements.

Our Advantages

Material Capacity

Rubber Products Production Ability

The vulcanizing presses have many types to match to different products, 200tons, 250tons, 350tons and others, the rubber

production line can full day 24 hour s to produce, the workers have more than 10 years production processing experience , our

factory always supply the goods to the main car markers in China for many years.

Except the presses, we also have spraying process and degreasing process to Metal parts , sand blasting and shot blasting machines.

Plastic Production Line

The plastic injection machines can make

the hose, spools, clips, caps, dust covers, pads, plugs, handles and other customized plastic parts.

The plastic material include the

ABS, TPE, PET, TPU, PP, PE, NYLON, PVC, GPPS, POM, etc

.

Plastic production line has

high auto computer

to control the processing,

m

echanical arm

assistance, which can reduce human errors.

Lab design and Technique

Our lab has

durometer, h

ydrometer, thickness guage,

electronic tension tester,

salt spray test chamber

,

l

ow temperature brittleness tester,

xenon lamp weathering tester, sulfur analyzer, aging tester,

ozone tester

,

image measuring instrument,

vibration & torsion machine

,

etc.

Our engineers have the w

ork experience of Fortune 500 companies,

they are reponsible for the material compund deisgn, 2D/3D drawings making, moulds processing, products quotation and deal with the daily

problem in the production.

Packing&Shipping

Packing: Cartong packing as customer's requirements.

FAQ

Any questions, please directly contact with us in Alibaba, thank you so much.

We support the customized parts for every customer, we can design and make what you want.

Hot Searches