- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UHMWPE/UPE/PE1000/PE500

-

Thickness:

-

6-200mm

-

Size:

-

Custom Size

-

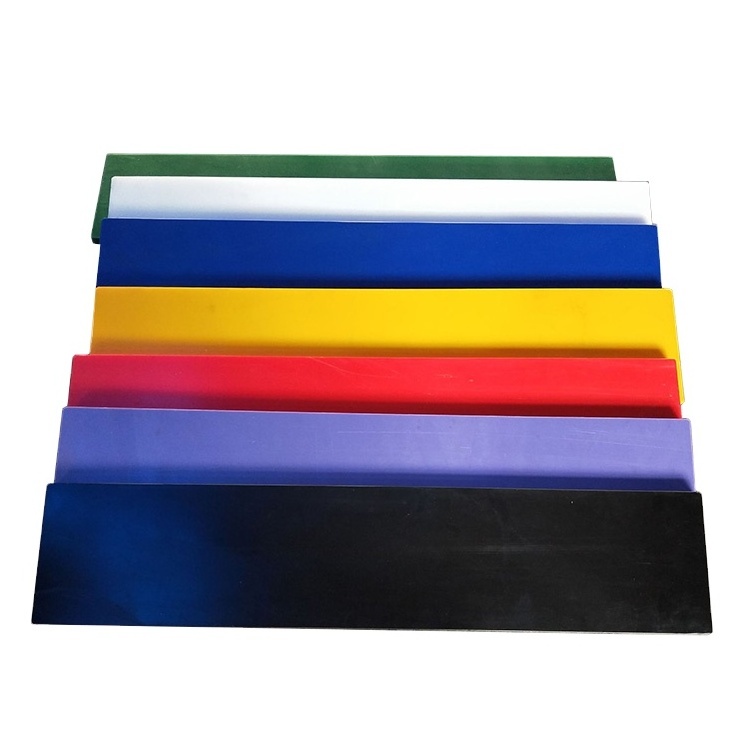

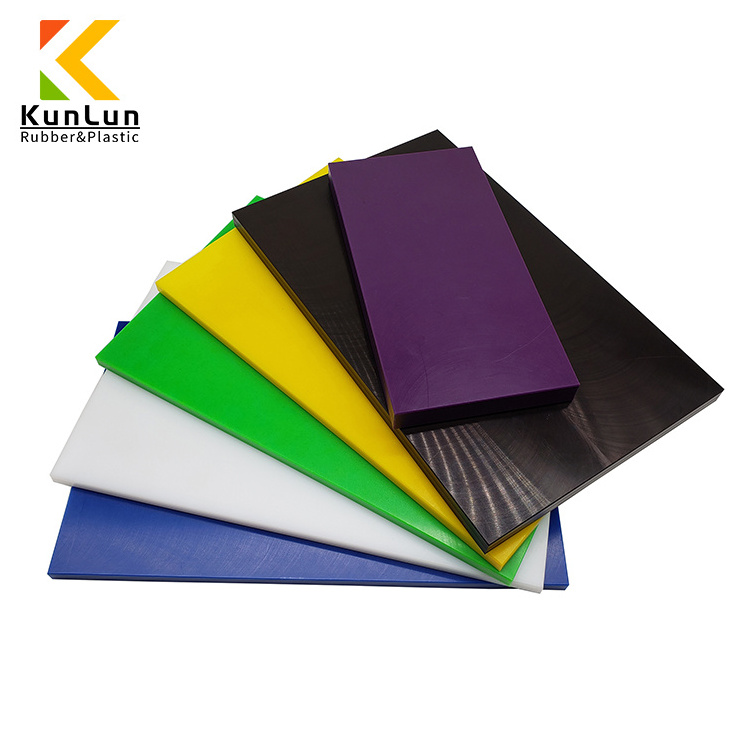

Color:

-

White, Black, Red, Green, Blue & Customized

-

Density:

-

0.93-0.97g/cm3

-

Molecular weight:

-

3million -9million

-

Tensile strength:

-

27MPa

-

Elongation at break:

-

400%

-

Abrasion:

-

100%

-

Coefficient of Friction:

-

0.1~0.2

-

Certificate:

-

ISO9001:2015

-

Feature1:

-

Wear-resistance;Self-lubricating;Antistatic

-

Feature2:

-

Impact Resistance;Corrosion Resistant

Quick Details

-

Processing Service:

-

Cutting, Moulding, Milling, CNC machining, Drilling, Turning

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Kunlun

-

Model Number:

-

UHMWPE/UPE/PE1000/PE500

-

Thickness:

-

6-200mm

-

Size:

-

Custom Size

-

Color:

-

White, Black, Red, Green, Blue & Customized

-

Density:

-

0.93-0.97g/cm3

-

Molecular weight:

-

3million -9million

-

Tensile strength:

-

27MPa

-

Elongation at break:

-

400%

-

Abrasion:

-

100%

-

Coefficient of Friction:

-

0.1~0.2

-

Certificate:

-

ISO9001:2015

-

Feature1:

-

Wear-resistance;Self-lubricating;Antistatic

-

Feature2:

-

Impact Resistance;Corrosion Resistant

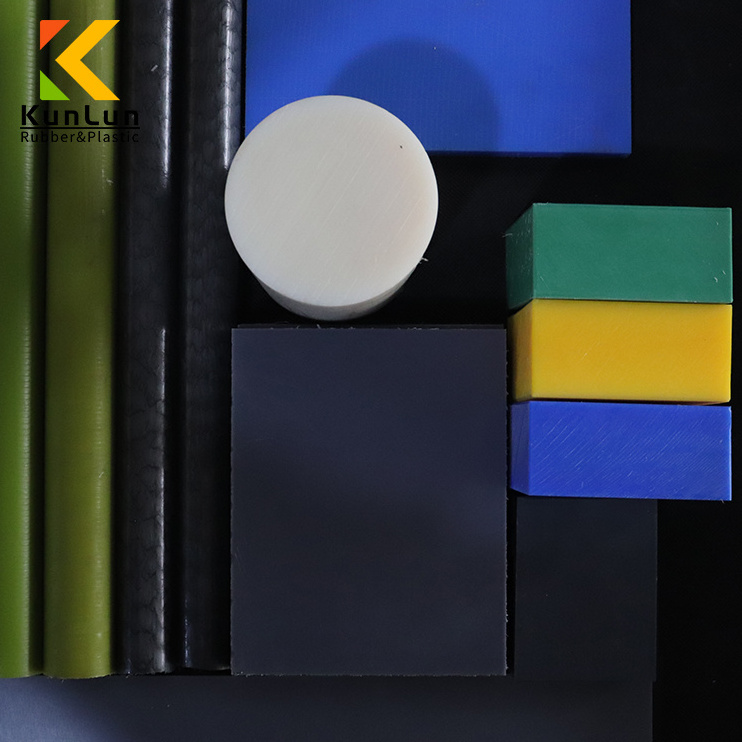

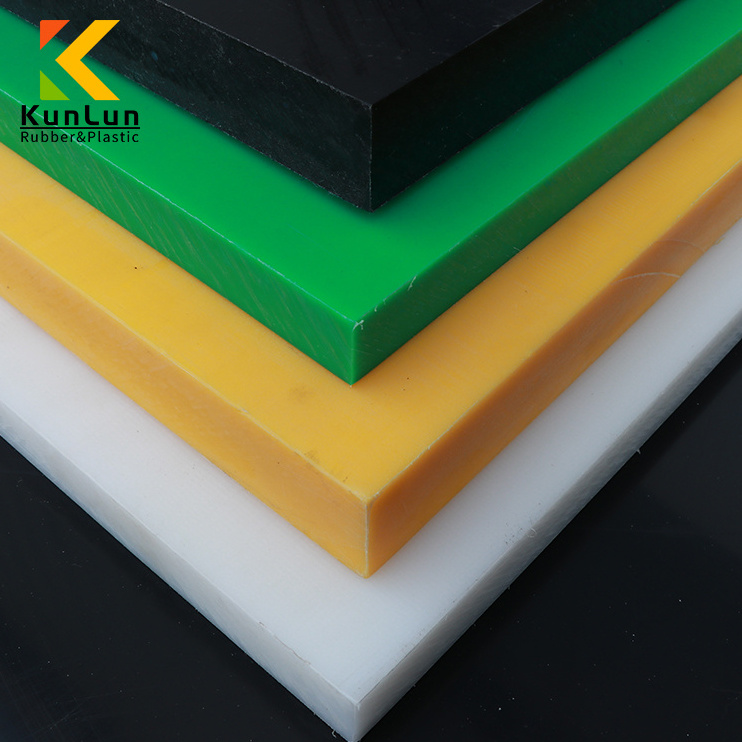

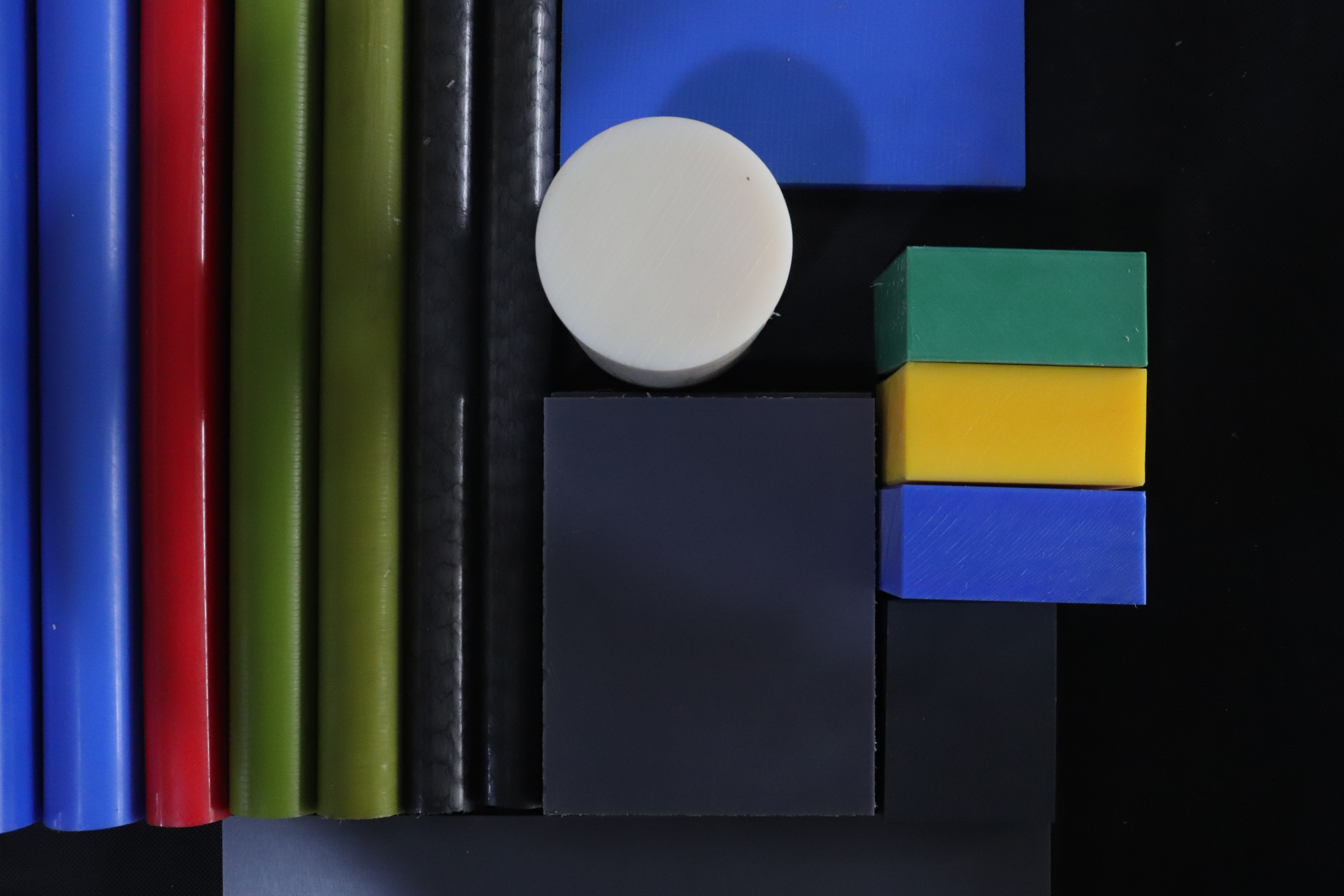

Products Description

UHMWPE sheets

Ultra-high molecular weight polyethylene (UHMWPE)

is a thermoplastic engineering plastic

with a molecular weight of 3–9 million g/mol

that combines the superior properties of all plastics. The mechanical properties are higher than normal

HDPE

, specifically its

wear resistance, impact resistance,small low-temperature wear coefficient, stress cracking resistance, high-temperature creep resistance, low friction coefficient, self-lubrication,

and excellent

chemical corrosion resistance, fatigue resistance, noise damping, nuclear radiation resistanc

e

and other excellent properties. It can replace carbon steel, stainless steel, bronze and other materials in

textile, papermaking, food machinery, transportation, medical, coal mining, chemical industry

and other sectors.

Features:

1.Extremely high

wear resistance

2. Extremely strong

impact resistance

3. Excellent

self-lubrication

4. Excellent

chemical resistance

5. Excellent

impact energy absorption

6. Good

low temperature resistance

7. Hygienic and non-toxic

8. Non-stickiness

9. Low

water absorption

10. Aging resistance

11. Energy absorption

12.

Flame retardancy

Applications:

1. Conveyor

machinery

2. Food

machinery

3. Paper making machinery

4. Textile machinery

5. Construction

industry

6. Chemical industry

7. Port machinery

8. General equipment

9. Sports

10.

Medical industry

11. Refrigeration machinery, shielding plates of atomic energy power plants, electroplated parts, ultra-low temperature mechanical parts

Specification

|

Mold Size table

|

|

|

||

|

Width×Length(mm)

|

Thickness

|

Color

|

||

|

1250×4040

|

6-200mm

|

White

Black

Green

Yellow

Blue

Red

Orange

customized

|

||

|

1350×2550

|

|

|

||

|

1350×4170

|

|

|

||

|

1550×4170

|

|

|

||

|

1650×6150

|

|

|

||

|

2020×3030

|

|

|

||

|

2150×5370

|

|

|

||

|

PHYSICAL AND MECHANICAL PROPERTIES OF UHMWPE

|

|

|

|

|

||||

|

PROPERTY

|

TEST METHOD

|

UNIT

|

TYPICAL VALUE

|

|

||||

|

|

|

|

VIRGIN

|

REGENERATED

|

||||

|

Density

|

ISO 1183, GB/T 1033(ASTM D792)

|

g/cm3

|

0.93 – 0.95

|

0.94-0.96

|

||||

|

Molecular Weight

|

Viscometric

|

g/mol

|

≥4 × 106

|

≥3 × 106

|

||||

|

Friction Coefficient

|

ISO 8295,GB/T10006(ASTM D1894)

|

---

|

0.15-0.20

|

0.15-0.20

|

||||

|

Yield Strength

|

ISO 15527, GB/T 1040(ASTM D638)

|

N/mm2

|

15-20

|

15-20

|

||||

|

Breaking Strength

|

ISO 15527, GB/T 1040(ASTM D638)

|

|

≥30

|

≥25

|

||||

|

Elongation at Break

|

ISO 15527, GB/T 1040(ASTM D638)

|

%

|

≥50

|

≥50

|

||||

|

Abrasion Index (Sand-slurry)

|

ISO 15527, GB/T 1040(ASTM D638)

|

-

|

~100

|

130-150

|

||||

|

Impact Strength (with V-notch)

|

ISO 11542-2,GB/T 1843(ASTM D256A)

|

kJ/m2

|

≥130

|

≥70

|

||||

|

Hardness

|

ISO 868 / GB/T 2411(ASTM D2240)

|

Shore D

|

61-63

|

63-66

|

||||

|

Operating Temperature

|

-

|

°C

|

-100 to +80

|

-100 to +80

|

||||

|

Thermal Expansion

|

ISO 11359-2/GB/T 36800.2(ASTM D696-03)

|

K-1

|

≈ 2 × 10-4

|

≈ 2 × 10-4

|

||||

|

Melting Point

|

ISO 11357-3, GB/T 19466.3(ASTM D3418)

|

°C

|

133 – 137

|

133 – 137

|

||||

|

Actual properties need to be confirmed by order.

The above properties need to be tested by manufacturer or third party testing laboratory. |

|

|

|

|

||||

Details Images

Recommend Products

Hot Searches