- Product Details

- {{item.text}}

Quick Details

-

Application:

-

stamping parts

-

Width:

-

Customize

-

Grade:

-

copper

-

Model Number:

-

C2680 C2720 C2600

-

Brand Name:

-

Longze

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

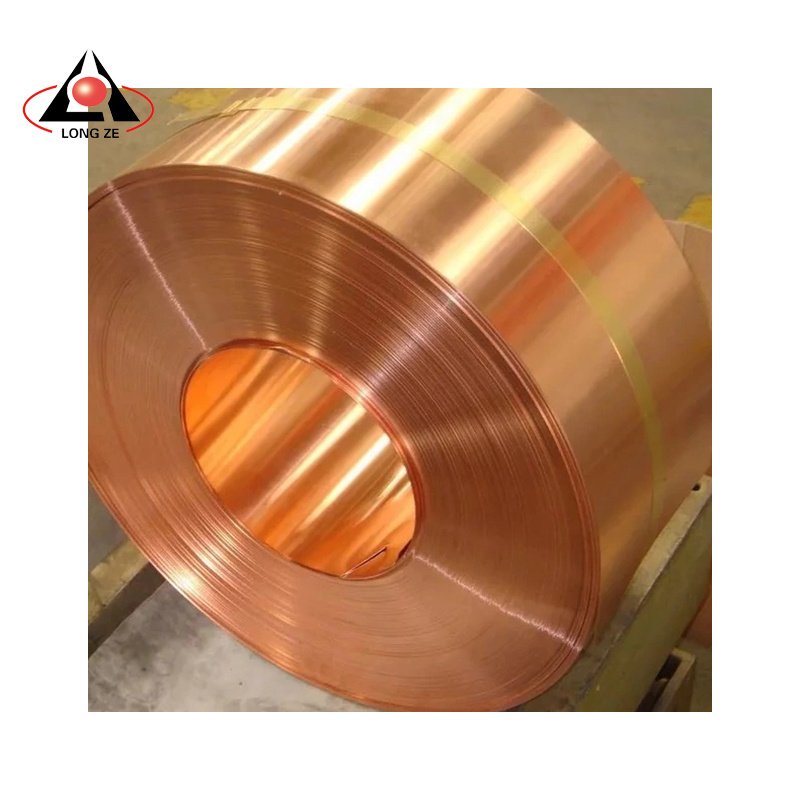

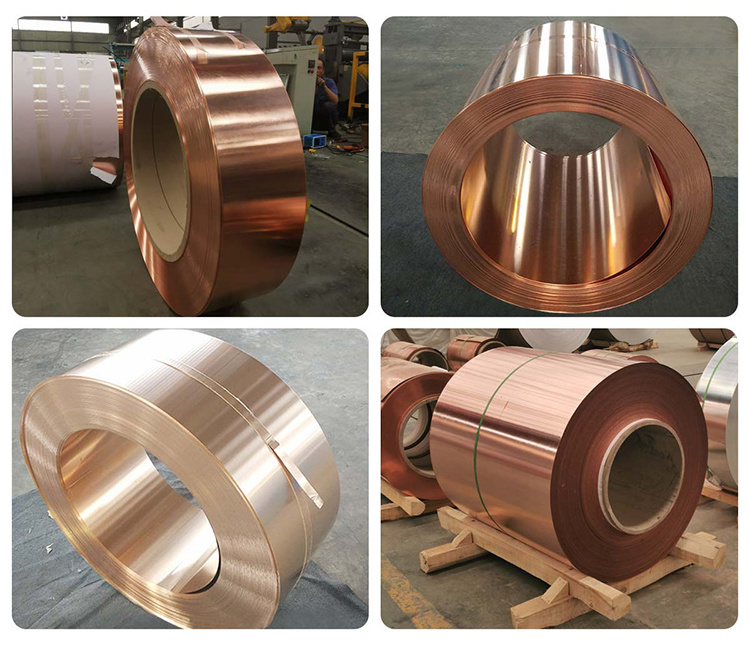

Copper Coil

-

Shape:

-

Strip Coil Roll

-

Keyword:

-

Copper Roll Coil

-

Type:

-

Plate Coil

-

Name:

-

99.9% Pure Copper Tape 25

-

Standard:

-

JIS ASTM DIN EN ISO

-

Hardness:

-

1/2 Hard/1/4Hard/ Hard

-

Surface:

-

Bright

-

MOQ:

-

100kg

-

Package:

-

Standard Seaworthy Package

Quick Details

-

Material:

-

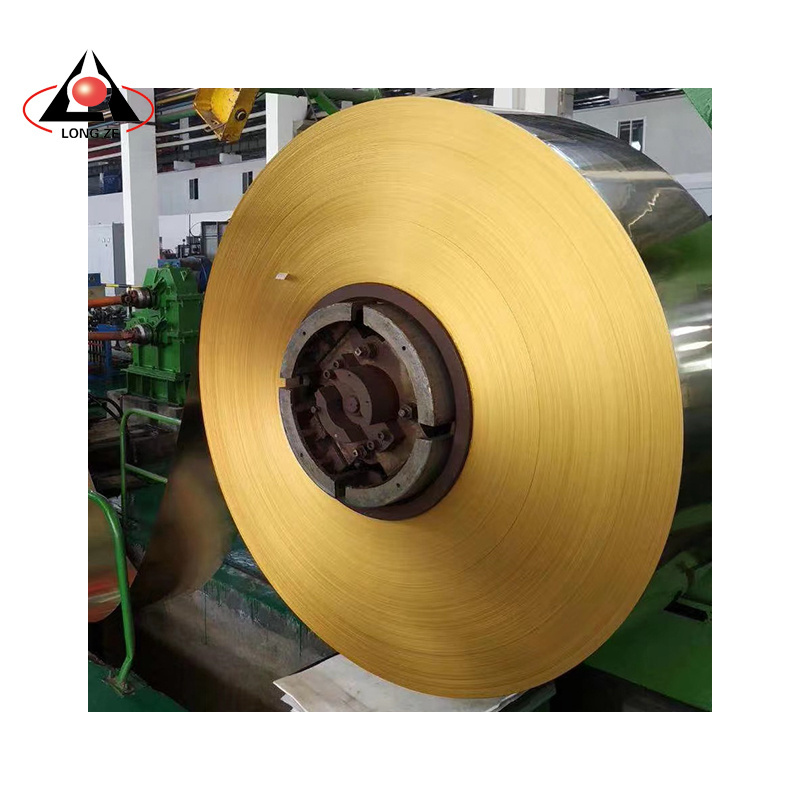

Bronze

-

Cu (Min):

-

69%

-

Alloy Or Not:

-

Is Alloy

-

Application:

-

stamping parts

-

Width:

-

Customize

-

Grade:

-

copper

-

Model Number:

-

C2680 C2720 C2600

-

Brand Name:

-

Longze

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

Copper Coil

-

Shape:

-

Strip Coil Roll

-

Keyword:

-

Copper Roll Coil

-

Type:

-

Plate Coil

-

Name:

-

99.9% Pure Copper Tape 25

-

Standard:

-

JIS ASTM DIN EN ISO

-

Hardness:

-

1/2 Hard/1/4Hard/ Hard

-

Surface:

-

Bright

-

MOQ:

-

100kg

-

Package:

-

Standard Seaworthy Package

Product Description

|

item

|

value

|

|

Application

|

ground system

|

|

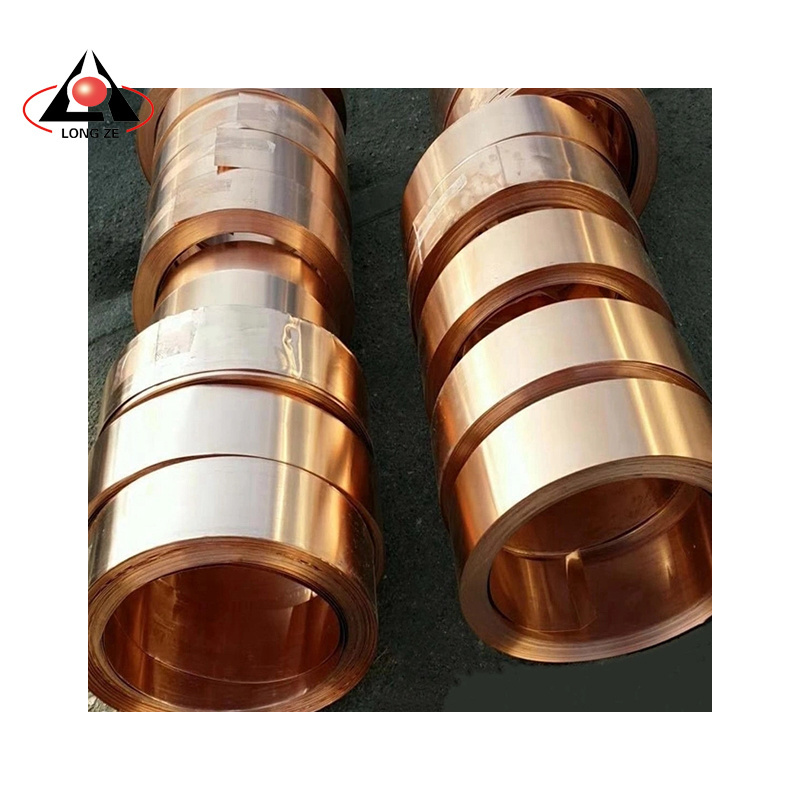

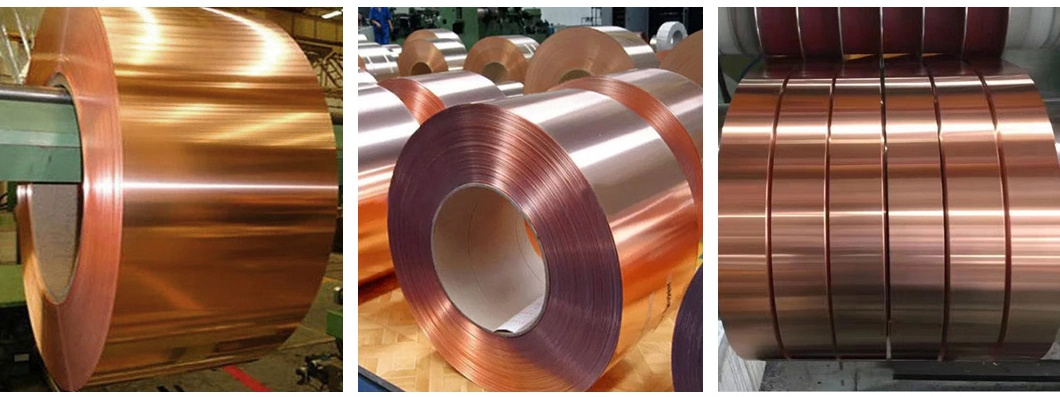

Width

|

0.1mm-5mm

|

|

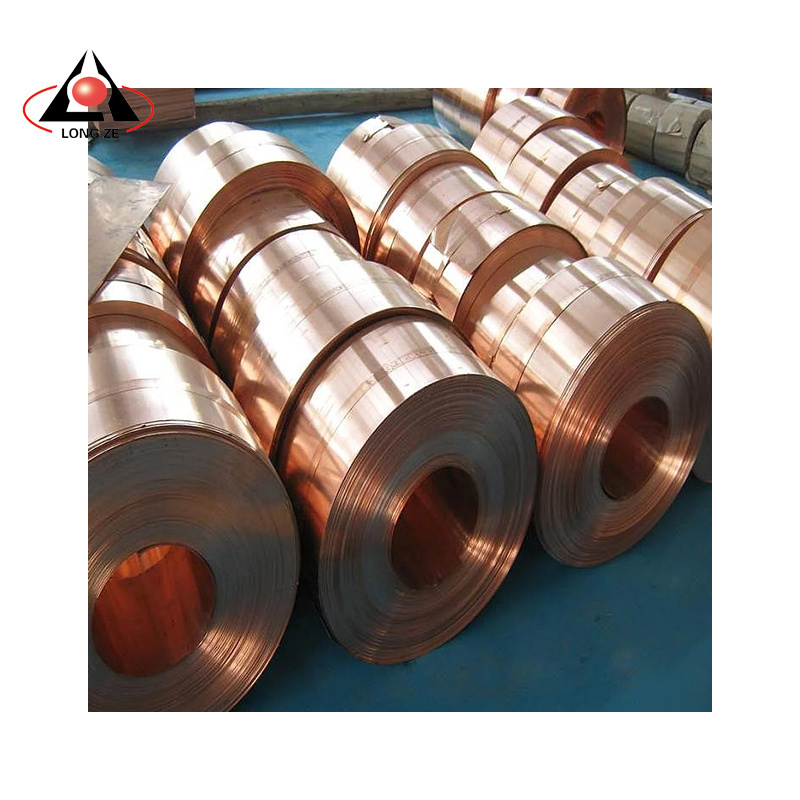

Material

|

Brass

|

|

Grade

|

COPPER

|

|

Cu (Min)

|

99.9%

|

|

Alloy Or Not

|

Non-Alloy

|

|

Model Number

|

c10100 c12000 c18150

|

|

Brand Name

|

Junhuitiancheng

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching

|

|

Price Term

|

CIF CFR FOB Ex-Work

|

|

Payment terms

|

30%+70% TT

|

|

Purity

|

99.90%~99.9%

|

|

Alloy Or Not

|

Non-Alloy

|

|

Width

|

5mm/10mm/20mm etc

|

|

Thickness

|

0.1-5mm

|

|

Grade

|

Pure Copper

|

|

Shape

|

Strip Coil Roll

|

|

Length

|

20M 50M ro customized

|

|

Delivery time

|

10-25 Days

|

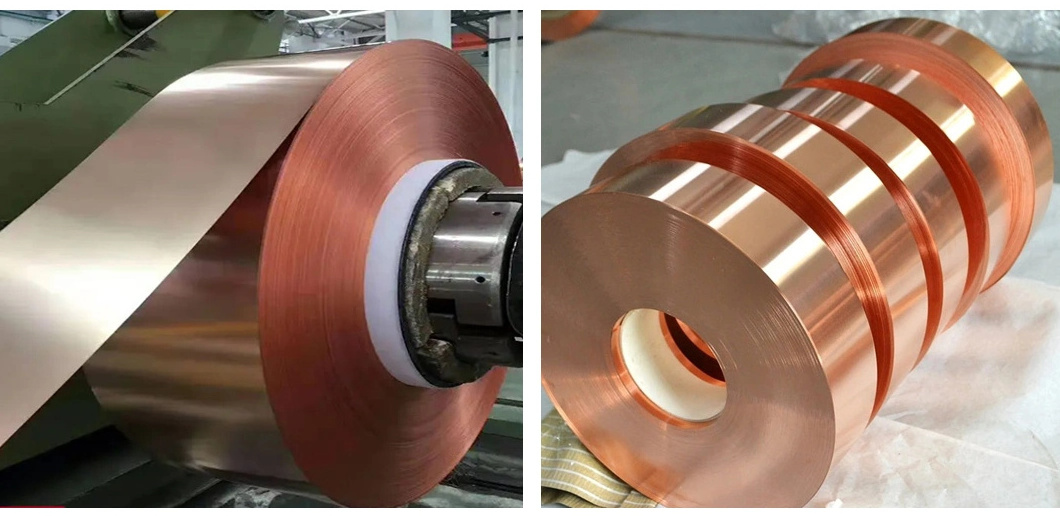

Product Display

Surface and use of copper plate

|

Surface Finish

|

Definition

|

Application

|

|

2B

|

Those finished, after cold rolling, by heat treatment, picking or other equivalent treatment and lastly by cold rolling to given

appropriate luster. |

Medical equipment, Food industry,Construction material, Kitchen utensils.

|

|

BA

|

Those processed with bright heat treament after cold rolling.

|

Kitchen utensils, Electric equipment, Building construction.

|

|

NO.3

|

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001.

|

Kitchen utensils, Building construction.

|

|

NO.4

|

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001.

|

Kitchen utensils, Building construction, Medical equipment.

|

|

HL

|

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size.

|

Building construction.

|

|

NO.1

|

The surface finished by heat treament and picking or processes corresponding there to after hot rolling.

|

Chemical tank, pipe.

|

Chemical composition

|

Grade

|

Cu

|

Pb

|

Fe

|

Zn

|

Others

|

|

C21000

|

94.0-96.0

|

0.03

|

0.05

|

margin

|

|

|

C22000

|

89.0-91.0

|

0.05

|

0.05

|

margin

|

|

|

C22600

|

86.0-89.0

|

0.05

|

0.05

|

margin

|

|

|

C23000

|

84.0-86.0

|

0.05

|

0.05

|

margin

|

|

|

C23030

|

83.5-85.5

|

0.05

|

0.05

|

margin

|

Si :0.20-0.40

|

|

C23400

|

81.0-84.0

|

0.05

|

0.05

|

margin

|

|

|

C24000

|

78.5-81.5

|

0.05

|

0.05

|

margin

|

|

|

C24080

|

78.0-82.0

|

0.2

|

-------

|

margin

|

Al :0.1

|

|

C26000

|

68.5-71.5

|

0.07

|

0.05

|

margin

|

|

|

C26130

|

68.5-71.5

|

0.05

|

0.05

|

margin

|

As :0.02-0.08

|

|

C26200

|

67.0-70.0

|

0.07

|

0.05

|

margin

|

|

|

C26800

|

64.0-68.5

|

0.15

|

0.05

|

margin

|

|

|

C27000

|

63.0-68.5

|

0.1

|

0.07

|

margin

|

|

|

C27200

|

62.0-65.0

|

0.07

|

0.07

|

margin

|

|

|

C27400

|

61.0-64.0

|

0.1

|

0.05

|

margin

|

|

|

C28000

|

59.0-63.0

|

0.3

|

0.07

|

margin

|

|

|

C31400

|

87.5-90.5

|

1.30-2.50

|

0.1

|

margin

|

|

|

C31600

|

87.5-90.5

|

1.30-2.50

|

0.1

|

margin

|

Ni :0.7-1.20,P :0.04-0.1

|

|

C32000

|

83.5-86.5

|

1.50-2.20

|

0.1

|

margin

|

Ni :0.25

|

|

C33000

|

65.0-68.0

|

0.25-0.70

|

0.07

|

margin

|

|

|

C33200

|

65.0-68.0

|

1.5-2.5

|

0.07

|

margin

|

|

|

C33500

|

62.0-65.0

|

0.25-0.70

|

0.15

|

margin

|

|

|

C34000

|

62.0-65.0

|

0.8-1.5

|

0.15

|

margin

|

|

|

C34200

|

62.0-65.0

|

1.5-2.5

|

0.15

|

margin

|

|

|

C34500

|

62.0-65.0

|

1.5-2.5

|

0.15

|

margin

|

|

|

Grade(China)

|

Grade(Japan)

|

Temper

|

Vickers Hardness (HV)

|

Tensile strength(Mpa)

|

Elongation(%)

|

|

T2/T3/TP1/TP2

|

C11000/C1201

C1220.etc. |

M

|

-

|

≥290

|

≥40

|

|

|

|

Y4

|

75-125

|

325~410

|

≥35

|

|

|

|

Y2

|

85-145

|

340~460

|

≥25

|

|

|

|

Y

|

105-175

|

390~530

|

≥13

|

|

|

|

T

|

-

|

≥490

|

-

|

Product features

Customized Service

Hot Searches