- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

ML-PZJ138

-

Size:

-

185*54*35CM

-

Manufacturing Technique:

-

3D design-CNC mouding

-

Warranty:

-

1 Year

-

Type:

-

for Nissan 400Z

-

color:

-

High polished black

-

Installation:

-

3m tape

-

process:

-

Prepreg dry carbon

-

surface:

-

3k twill weave

-

OEM& ODM services:

-

Easy customized order with car data

-

manufacture:

-

20000sqm modern carbon factory

-

Certifications:

-

TSI16949, ISO9001

Quick Details

-

OE NO.:

-

ML-PZJ138

-

Car Make:

-

for Nissan 400Z side skirts

-

Brand Name:

-

Modify Luxury

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

ML-PZJ138

-

Size:

-

185*54*35CM

-

Manufacturing Technique:

-

3D design-CNC mouding

-

Warranty:

-

1 Year

-

Type:

-

for Nissan 400Z

-

color:

-

High polished black

-

Installation:

-

3m tape

-

process:

-

Prepreg dry carbon

-

surface:

-

3k twill weave

-

OEM& ODM services:

-

Easy customized order with car data

-

manufacture:

-

20000sqm modern carbon factory

-

Certifications:

-

TSI16949, ISO9001

Related Products

Product Description

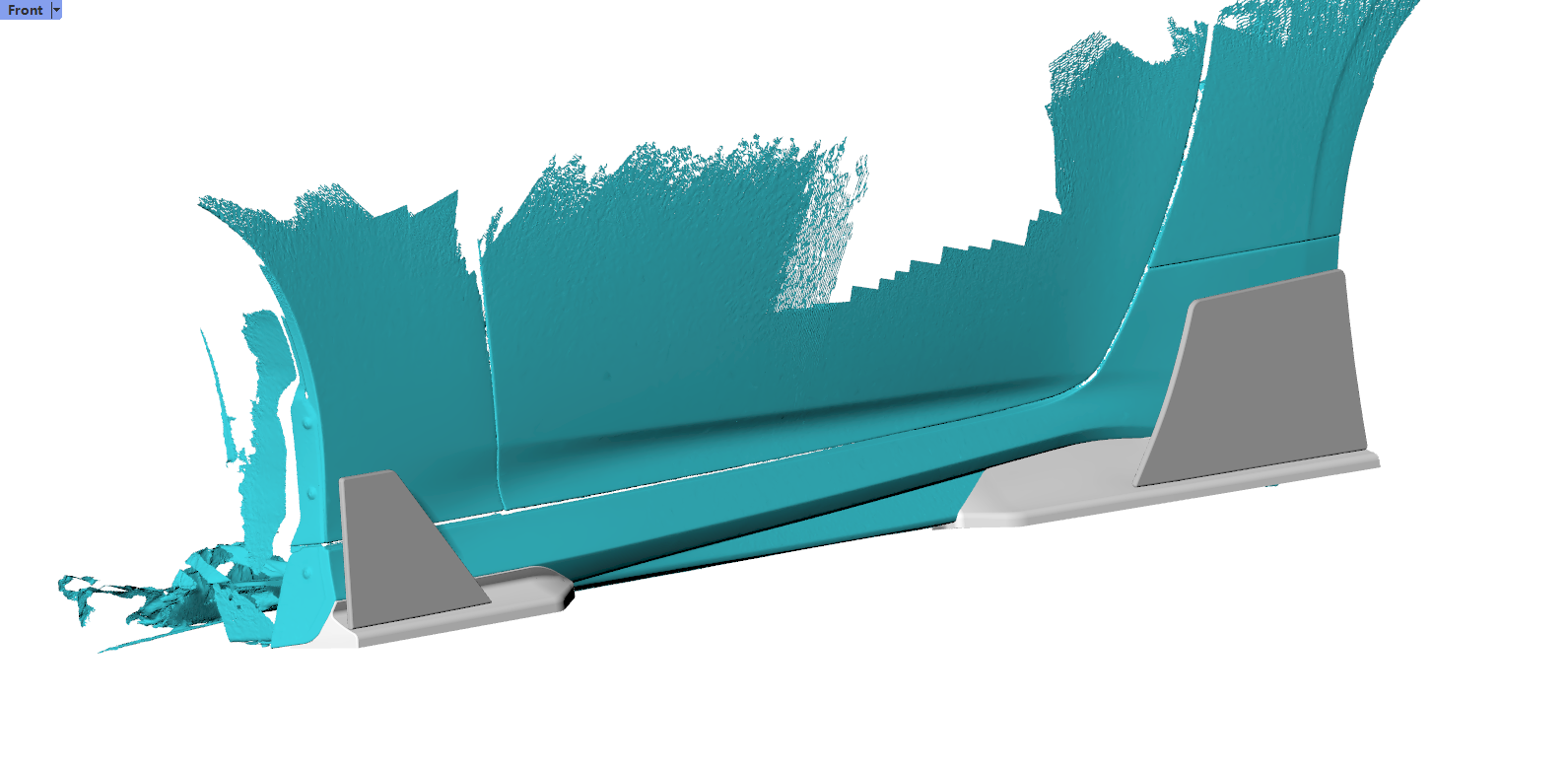

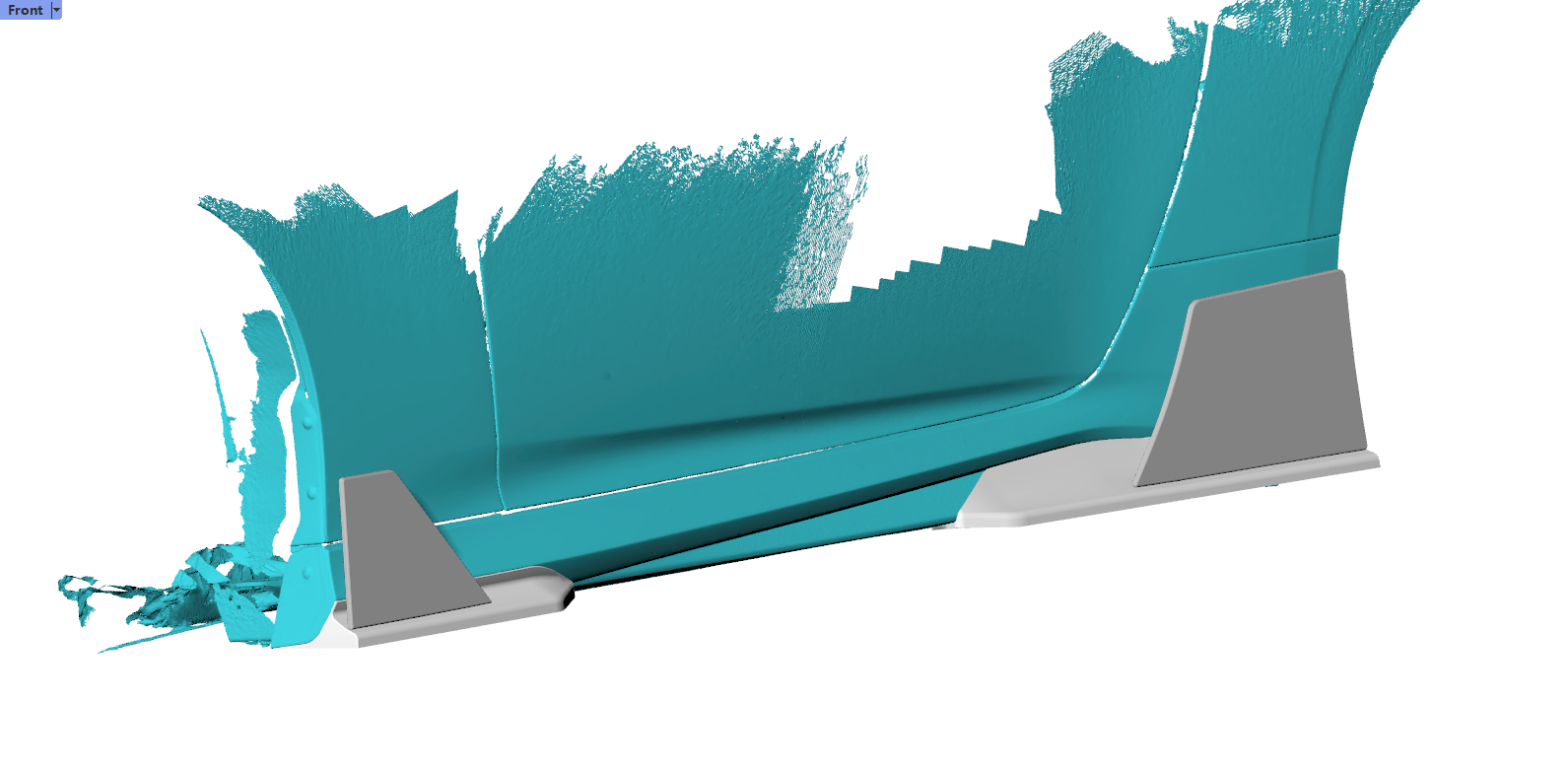

400Z Prepreg Dry Carbon Fiber Side Skirts for Nissan 400Z 2023

Pls kindly check the above fitment information or send us car pics before buying, thanks a lot!

1.

400Z Prepreg Dry Carbon Fiber Side Skirts for Nissan 400Z 2023

2.

3*3 Twill Weave Carbon Fiber material with high Quality UV-Protected Clear Coating to prevent from yellowing and hold its high glossy finish

3. Original car 1:1 laser scanning, high precision data,CNC moulding,test installation on real cars, fitment guaranteed

4.

New Manufacturing Process, autoclave processing, more lightweight and durable than other ordinary carbon parts

|

Product Name

|

400z side skirts

|

Material

|

dry carbon fiber

|

|

Brand

|

Jcsportline

|

Colour

|

Carbon Black

|

|

Process

|

Autoclave prepreg

|

Surface

|

3k Twill Weave

|

|

Manufacture

|

20000sqm modern carbon factory

|

Installation

|

Add ON. Glue tape or screws

|

|

Manufacturing Technique

|

3D design - CNC mouding - Autoclave

|

OEM & ODM Services

|

Easy customized order with car data

|

This car parts is made from high-quality carbon fiber material and is designed to match the OEM specs of your car.

Plus,the quality is approached to the original kit - so you know it'll last.

Best of all, there's no MOQ required - so you can order as many or as few as you like.

Detailed Images

Our Advantages

Designed Capacity

One stop station to turn your concept into reality.

JC SPORTLINE solved the painfull points of the installation problem of carbon parts with real car 3d data and CNC molding

Our designers are the post-80s generation with more than 10 years of design experience. the company not only pays attention to design creativity, but also pays more attention to customer satisfaction and service quality. We constantly innovate and improve the production level of 3D rendering, 2D animation and virtual reality, and use cutting-edge 3D rendering technology and virtual reality technology to constantly meet customers' needs for product design services.

Our designer has rich exprience in carbon production, so the design can avoid the mass production problem.

Company Introduction

Jcsportline a high-grade and brand of car modification industry scale, a set of product development, wholesale and retail of carbon fiber car modification supplies company.

factory covers an area of 70000sqm and belongs to the private property of the company.

Jcsportline passed IS09001 And ts16494( Originally, there was no strit standard in the carbon fiber aftermarket tuning parts, through cooperating with OE brand clients,jcsportline get the successful standard for carbon parts, and become the key vendor for these oe clients in carbon catergory.

Jcsportline invests a lot in top designers and engineers in composite industry . such as aerospace, aviation, medical devices and so on, In 2021, 20 more such top technicians were recruited to join the jcsportlien R & D team to continuously test new processes and provide customers with high-quality and high-level products

As for design, our designers have more than 10 years of experience in the combination of design and carbon fiber production. They are resident in the factory and the production line to optimize the structure of abrasive tools to ensure that the products produced meet the beauty of design and the feasibility of production, rather than simple product designers. Jcsportline provide one stop service, from design to abrasive machining (our CNC) , Equipment for processing le high-temperature resin abrasives, which is also the industry leader.With regard to molds, we have studied for more than 10 years and developed different abrasive materials to ensure excellent quality and adapt to OE Different demands based on clients’ requirment and burgets.

Body lightweight & Promote energy conservation and emission reduction

The logo of Jcsportline reflects the youth, vitality, responsible attitude and spirit of Jinchi team.

JC Sportline adheres to the two spirits of "achievement+contribution". For more than ten years, the company's turnover has grown at an annual rate of more than 30%, creating value for the entire surrounding environment and the world.

Manufacturing Technique

More than 30sets CNC in factory

The CNC workshop covers an area of 1000 square meters. The company has 5 professional engineers responsible for mold production, product calibration and equipment maintenance.

Compression Mold

It can adapt to automatic feeding and taking out of products. High production efficiency, easy to realize professional and

automatic production. For tail wing and other products, the problem of thick clamping line caused by traditional process clamping can be solved by forming Mass production, the price is relatively low. It solves the problem of low production capacity of carbon fiber products. One mold can produce 8-16 products a day.

automatic production. For tail wing and other products, the problem of thick clamping line caused by traditional process clamping can be solved by forming Mass production, the price is relatively low. It solves the problem of low production capacity of carbon fiber products. One mold can produce 8-16 products a day.

Autoclave

It covers an area of 1200 square meters, with 4 engineers and more than 100 employees. Responsible for production of high-end products and maintenance of workshop equipment. It is equipped with 8 autoclaves and 3 intelligent CNC cutting machines. More than 200 dry carbon products are produced every day.

Standardized Management

Carbon pattern worker will get information of carbon patten and carbon angle hrough the LED display screen and pads in each workshop.

Certificate

Certificate Introduction

Certificate Introduction

Certificate Introduction

Hot Searches