- Product Details

- {{item.text}}

Quick Details

-

Surface Treatment:

-

Polished

-

Size:

-

700mm, CUSTOMER

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

henger

-

Model Number:

-

HE-LD05011

-

Product name:

-

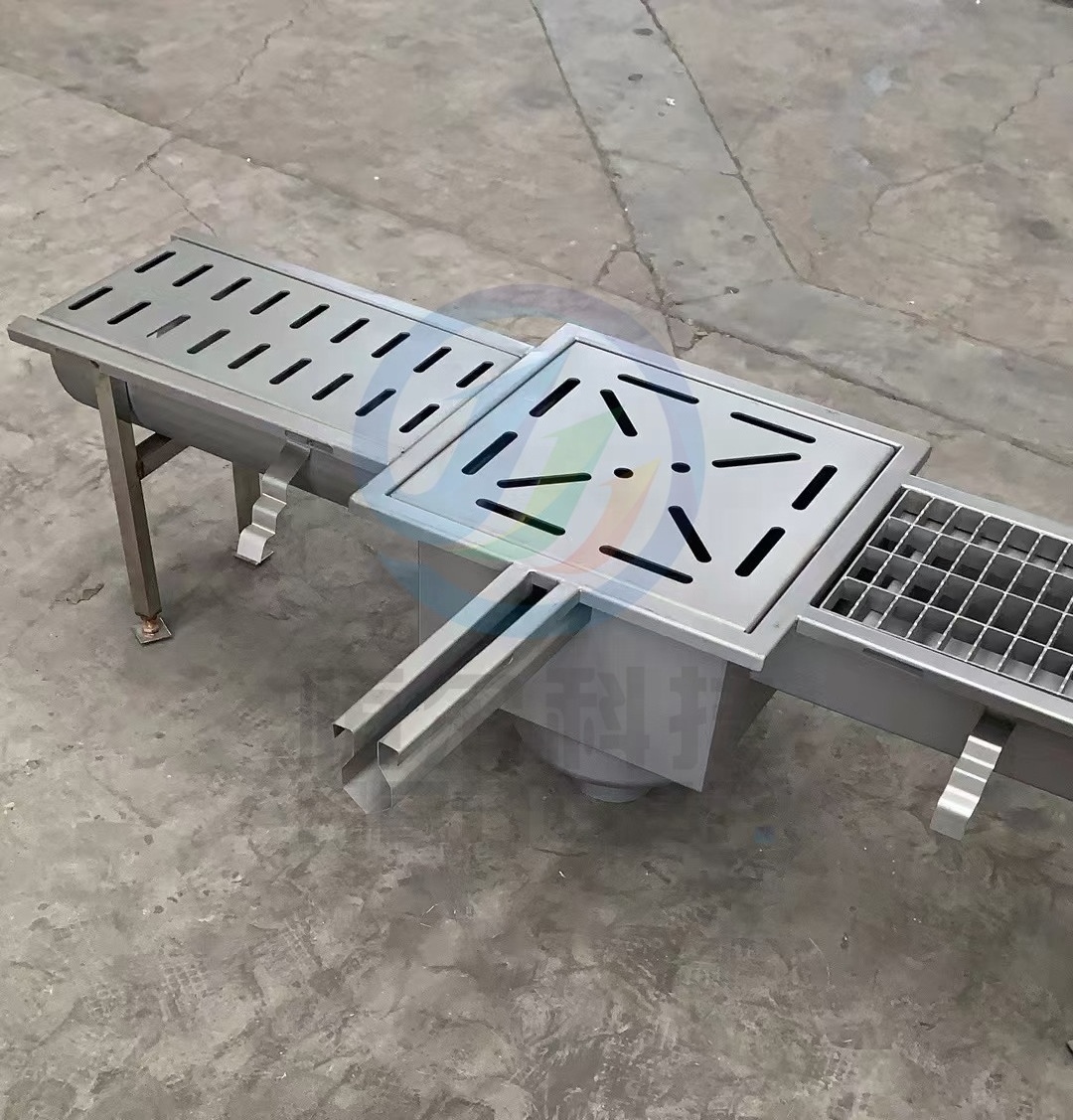

Stainless steel garage floor drain cover/floor grate/drain grate

-

Usage:

-

Public Drain Area

-

Certification:

-

ISO9001

-

MOQ:

-

10

-

Main Material:

-

SUS 304 (SUS 316 Acceptable)

-

Keyword:

-

Floor Drain Strainer

-

Brand:

-

HENGER

-

Thickness:

-

1.5mm/2mm

-

Package:

-

Customer's Special Packaging

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Workshop

-

Design Style:

-

Industrial

-

Surface Treatment:

-

Polished

-

Size:

-

700mm, CUSTOMER

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

henger

-

Model Number:

-

HE-LD05011

-

Product name:

-

Stainless steel garage floor drain cover/floor grate/drain grate

-

Usage:

-

Public Drain Area

-

Certification:

-

ISO9001

-

MOQ:

-

10

-

Main Material:

-

SUS 304 (SUS 316 Acceptable)

-

Keyword:

-

Floor Drain Strainer

-

Brand:

-

HENGER

-

Thickness:

-

1.5mm/2mm

-

Package:

-

Customer's Special Packaging

Product Description

HENGER One-stop Underground Drainage System Solution

There must be one pattern ideal for you !

ADVANTAGES

1. SUS304 stainless steel or SUS316L stainless steel, durable and not rusty;

2. Material thickness can be 1.5mm, 2.0mm, 2.5mm, 3.0mm;

3. The bottom is designed with rounded corners, no water, no dead corners, and easy to clean;

4. The bottom of the drainage ditch has a slope design to facilitate smooth water flow;

5. Folding design on the top of the drainage ditch increases the strength of the top of the drainage ditch, effectively ensuring that it is flush with the ground, it is convenient and firm.

6. Provide optimized solutions based on the design and actual conditions on site.

7. Provide installation guidance and on-site installation services.

The floor drain in the workshop should use U-shaped, S-shaped water seals with water to prevent insects and odors.

Specification

|

Material

|

304 stainless steel/ 201 stainless steel /316 stainless steel

|

|

Size

|

10/15/20/25//30/35/40 *58*2.5cm

|

|

Project Solution Capability

|

Graphic design, 3D model design, total solution for projects

|

|

Application

|

Workshop/Hospital/ Office building/Food factory/

|

|

Design Style

|

Industrial

|

|

Place of Origin

|

China

|

|

Surface Treatment

|

Polished

|

|

Style

|

Strainer

|

Workshop

Design Requirements for Drainage Ditch

1. The drainage of the workshop should be considered comprehensively with the drainage of the plant.

Different water ditches are used in different cleaning areas. For general cleaning areas and quasi-cleaning areas, open ditches are covered with stainless steel side rails. Hidden ditch must be made in high clean area.The indoor drainage (including floors) of the production workshop should be an open ditch without cover, and the open ditch should have a certain width (200~300mm), depth (150~400mm) and slope (greater than 1%), and the drainage slope of the workshop floor Should be 1.5~2%

2. The water pipeline should maintain a certain slope and flow from the clean area to the unclean area.

The flow of sewage flows from the high clean area to the low clean area. Design a certain slope to avoid pollution caused by dirty water discharge.

The slope of the main drainage pipe in the workshop should consider the location of the drainage outlet, its location and the slope of the main drainage pipe in the workshop should also consider the depth of the drainage pipe under the drainage outlet of the workshop and the reasonable location of the drainage ditch depth in the plant area.

3. The drainage pipeline should be leveled during construction.

There must be no unevenness and cracks to ensure the smooth drainage of the workshop, and there must be a certain arc at the turning point

Hot Searches