- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤ 100g, ≤ ±2%; 100-500g, ≤ ±1%, ≤ 100g, ≤±2%;100 - 500g, ≤±1%

-

Voltage:

-

3P 380/220V 50/60HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DAHE PACK

-

Dimension(L*W*H):

-

1500*760*1850mm

-

Weight:

-

160 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

powder and granule filling

-

Name:

-

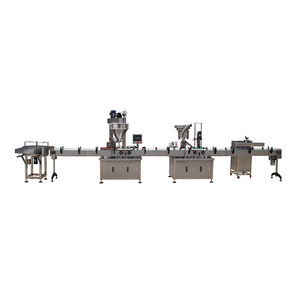

powder Dispenser Filling Machine fine powder packing machine

-

Filling Speed:

-

15 - 40 bottles per min

-

Air Supply:

-

6 kg/cm2 0.05m3/min

-

Total power:

-

1.2Kw

-

Total Weight:

-

160kg

-

Overall Dimensions:

-

1500*760*1850mm

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machinery Capacity:

-

2000BPH, customized

-

Packaging Material:

-

Glass, Metal, Plastic, Wood

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

≤ 100g, ≤ ±2%; 100-500g, ≤ ±1%, ≤ 100g, ≤±2%;100 - 500g, ≤±1%

-

Voltage:

-

3P 380/220V 50/60HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DAHE PACK

-

Dimension(L*W*H):

-

1500*760*1850mm

-

Weight:

-

160 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

powder and granule filling

-

Name:

-

powder Dispenser Filling Machine fine powder packing machine

-

Filling Speed:

-

15 - 40 bottles per min

-

Air Supply:

-

6 kg/cm2 0.05m3/min

-

Total power:

-

1.2Kw

-

Total Weight:

-

160kg

-

Overall Dimensions:

-

1500*760*1850mm

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2020

Products Description

Introductions:

1. This is a automatic auger type can/bottles metering filling machine ,designed for metering and filliing various dry powder into different rigid containers: Can/Bottle/Jar etc.

2. The Machine provides powder metering and filling functions.

3. Bottles and cans are introduced by conveyor belt combined with gating system.

4. There is a photo eye sensor for bottles detection so as to achieve bottle-fill ,no-bottle no-fill.

5. Automatic bottle postioning-filling-releasing,optional vibration and elevation.

6. Featured with compact design,stable performance,easy to operate and good cost performance!

2. The Machine provides powder metering and filling functions.

3. Bottles and cans are introduced by conveyor belt combined with gating system.

4. There is a photo eye sensor for bottles detection so as to achieve bottle-fill ,no-bottle no-fill.

5. Automatic bottle postioning-filling-releasing,optional vibration and elevation.

6. Featured with compact design,stable performance,easy to operate and good cost performance!

Product Parameters

|

Model

|

DH-Q1-D100

|

DH-Q1-D160

|

|

Container Size

|

Directly dosing by auger

|

Directly dosing by auger

|

|

Filling Speed

|

15-40 bottles per min

|

15-40 bottles per min

|

|

Filling Acuuracy

|

≤ 100g, ≤ ±2%; 100-500g, ≤ ±1%

|

≤ 500g, ≤ ±1%;>500g, ≤ ±0.5%

|

|

Filling Weight

|

1-500g

|

10-5000g

|

|

Total Power

|

1.2KW

|

1.6KW

|

|

Overall Dimensions

|

1500*760*1850mm

|

2000*970*2030mm

|

|

Power Supply

|

3P AC208-415V 50/60Hz

|

3P AC208-415V 50/60Hz

|

|

Total Weight

|

160kg

|

300kg

|

|

Hopper Volume

|

25L(Enlarged size 35L)

|

50L(Enlarged size 35L)

|

|

Optional Function

|

1.Container lifting and vibrating function

2.Container lifting and dosing by weighing function

|

1.Container lifting and vibrating function

2.Container lifting and dosing by weighing function

|

Application

Hot Searches