- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

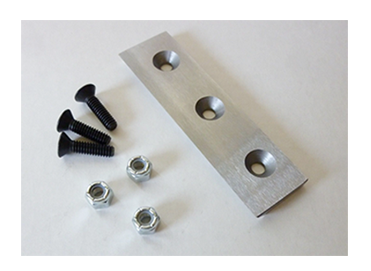

Chipper Blade

-

Type:

-

Wood cutting

-

Application:

-

Wood processing industry

-

Size:

-

customizable

-

Material:

-

HSS,A-8,SKD-11,6CrSi

-

Certification:

-

ISO9001 ,CE

-

Surface treatment:

-

Smooth and finely polished

-

Delivery Time:

-

3~20days

-

service:

-

Can be returned and exchanged within 90 days

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SKS

-

Weight (KG):

-

12 KG

-

Product name:

-

Chipper Blade

-

Type:

-

Wood cutting

-

Application:

-

Wood processing industry

-

Size:

-

customizable

-

Material:

-

HSS,A-8,SKD-11,6CrSi

-

Certification:

-

ISO9001 ,CE

-

Surface treatment:

-

Smooth and finely polished

-

Delivery Time:

-

3~20days

-

service:

-

Can be returned and exchanged within 90 days

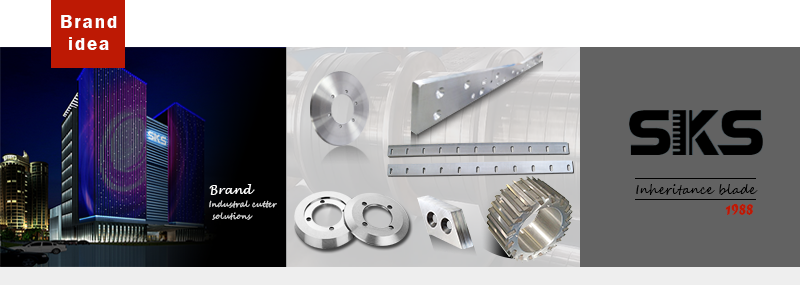

Brand

Standing at the junction of history and future, there’re Wright brothers invented and produced airplanes in the past.Today,Nanjing SKS brothers research, produce and develop the best mechanical blade from the last century. Time will take away many memories,Only inheritance is constant ...

Product information

Serviceable range

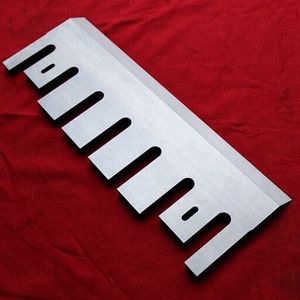

Our Chipper Blade mainly used for cutting the following wood raw materials: pine, miscellaneous wood, poplar, Chinese fir and other logs,stumps, branches, small-diameter wood, bamboo,veneer wood, cutting the leftover materials of secondary fuelwood,cotton stalks, other non-wood fiber stems, etc.

|

Model

|

Specification(mm)

|

Length

|

Width

|

Thickness

|

|

BX 216

|

600*180*20

|

600

|

180

|

20

|

|

BX 218

|

780*220*20

|

780

|

220

|

20

|

|

BX 218A

|

875*220*20

|

875

|

220

|

20

|

|

BX 2113A

|

780*220*20

|

780

|

220

|

20

|

|

BX 1710

|

258*75*6.5

|

258

|

75

|

6.5

|

|

BX 2110

|

540*220*20

|

540

|

220

|

20

|

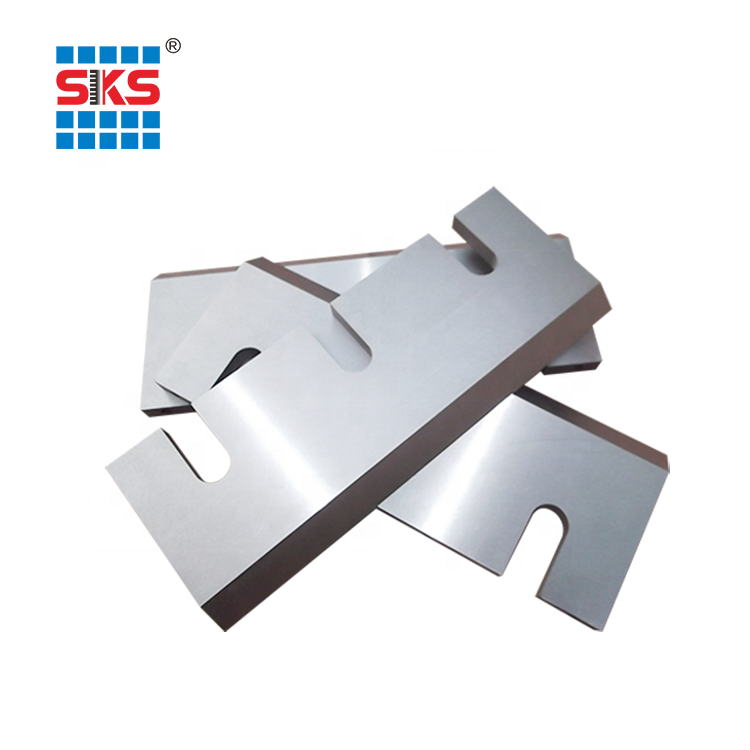

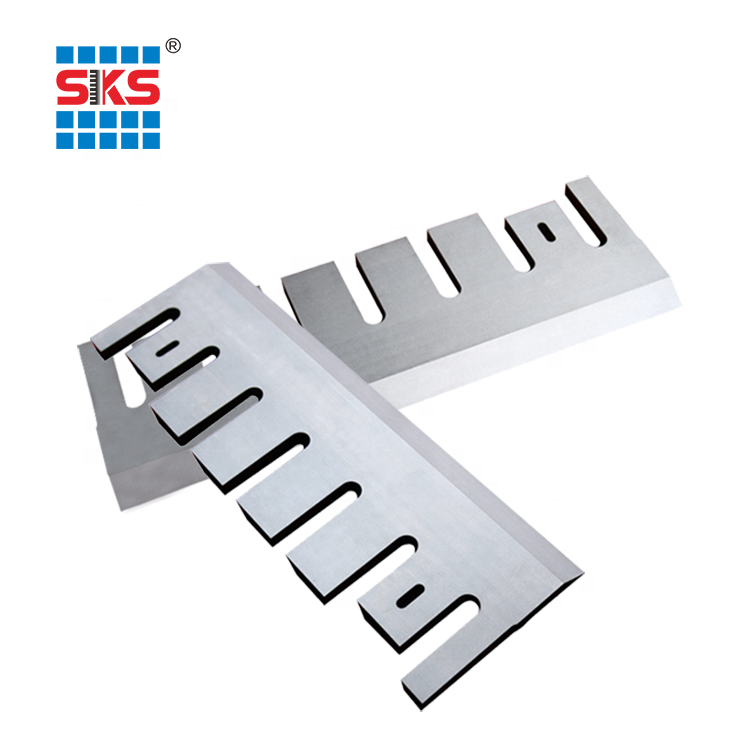

More benefits from SKS Chipper Blades:

◆

Precision ground finish (double grinding process)

◆

High toughness and long wear resistance

◆

Hardened cutting edge and soft the slot area

◆

Holes and slots are shiny and CNC milled for the highest precision.

◆

more capability to avoid cutting edge break, longer running life.

◆

Easy to change and reinstall

◆

Sharp cutting edges

Products Show

Process flow

Process flow

From the selection of product materials, every step of the process has been strictly inspected, and the quality is trustworthy.

Scenes to be used

Packing & Shipping

1, PE film or Kraft paper in anti-rust oil - keep air/water/humid away, thus rust-proofing.

2, Bubble film - increases the impact resistance ability.

3, Rubber Slip or Corrugated Angle - gives special care to knife edges.

4, Wood Screws crates - makes opening easier without damaging the crates

5, Corrugated boxes or plywood case - provide superior protection and stack-ability

2, Bubble film - increases the impact resistance ability.

3, Rubber Slip or Corrugated Angle - gives special care to knife edges.

4, Wood Screws crates - makes opening easier without damaging the crates

5, Corrugated boxes or plywood case - provide superior protection and stack-ability

Factory strength

The company occupies an area of 6,600 square meters, equipped with various process workshops and production areas. The factory has more than 100 production equipment including CNC machining centers, and has 10 heat treatment and material testing technicians. We have passed ISO9001, CE and SGS certification, and strictly abide by international quality standards.

Our factory has strong non-standard production ability, and we can make tailor-made according to customers' drawings and samples. Products are widely used in steel, paper, wood, plastic, rubber, textile and packaging industries. Since the company exported to the United States in 2008, it has been exported to dozens of countries including Indonesia, India, Japan, the Philippines, Malaysia, the United Kingdom, Italy, Turkey, Russia, and Mauritius. At the same time, the company's customer base includes well-known domestic and foreign companies, domestic and foreign OEM manufacturers, foreign tool dealers and even tool manufacturers.

Hot Searches