- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Driven Type:

-

Electirc & Pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Atpack

-

Dimension(L*W*H):

-

1500*800*1600mm

-

Weight:

-

500 KG

-

Function:

-

filling

-

Capacity:

-

5-38BPM

Quick Details

-

Machinery Capacity:

-

400BPH, 500BPH, 1000BPH

-

Packaging Material:

-

Glass, Metal, Plastic, Wood, Other

-

Filling Material:

-

Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±0.5%

-

Driven Type:

-

Electirc & Pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Atpack

-

Dimension(L*W*H):

-

1500*800*1600mm

-

Weight:

-

500 KG

-

Function:

-

filling

-

Capacity:

-

5-38BPM

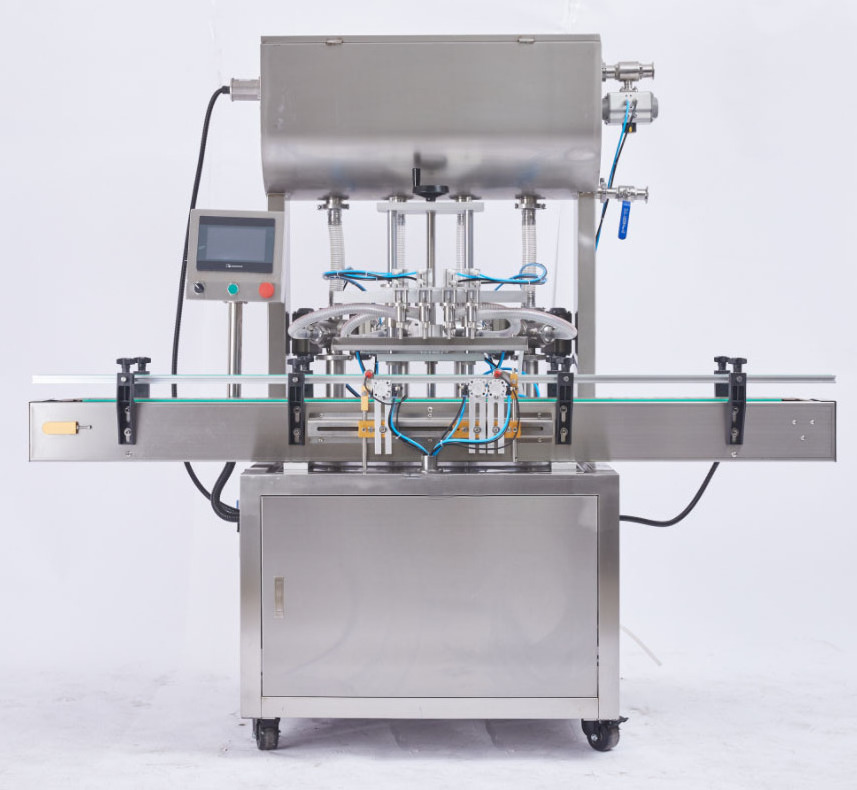

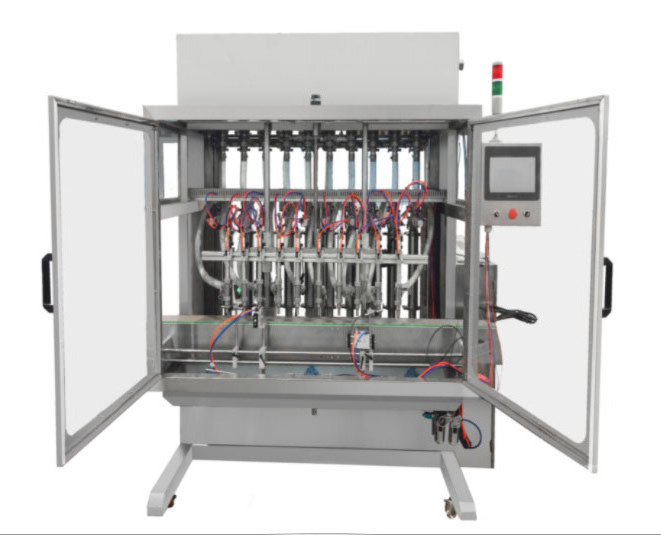

Product Description

VCF automatic paste filling machine with multi filling nozzles, filling volume adjustment system motor, PLC controlled by SIMENS (from Germany) or MITSUBISHI (from Japan) and intelligent touch screen. It's very easy to adjust the filling volume. Adopt FESTO (from Germany) or AIRTAC (from Taiwan) pneumatic components, Container position will be fixed by air-cylinder, we can adjust the position of filling heads according to the shape of the container, ensure the stable filling action. Drip proof system adopt air-cylinder control, it will plug up the filling nozzle, meanwhile adopts a new patent principle-vacuum pump back, completely avoid the material leak.

This paste filling machine also adapts to all kinds of paste, viscous paste filling. It is the ideal filling equipment of

pharmaceutical, chemical, food, cosmetics and other industries

This paste filling machine also adapts to all kinds of paste, viscous paste filling. It is the ideal filling equipment of

pharmaceutical, chemical, food, cosmetics and other industries

Features

1, Construction of the machine body: Whole filling machine produced by SUS304, materials touched parts are SS 316L, Measure up to

GMP standards;

2, Select PLC control system, touch screen operation panel can save multi-groups of datas;

3, Adopt lifting filling, ensure no bobble;

4, PLC controlled by: SIMENS (from Germany) or MITSUBISHI (from Japan);

5, Pneumatic parts adopt: AIRTAC (from Taiwan);

6, Filling nozzles with anti-leaking function;

7, Easy to operate, no bottle no filling, auto orientation detection;

8, Can equip with auto production line: bottle sorting, filling, cap feeding, capping, sealing, labeling, printing, packing and

etc.

9, Machine applied with Italy O-rings and mixing motor.

10, Adopting 180W mixing motor

11,Adopting Japan Omron heating controller

12, Filling set adopts preventing leaking and preventing silk nozzle

GMP standards;

2, Select PLC control system, touch screen operation panel can save multi-groups of datas;

3, Adopt lifting filling, ensure no bobble;

4, PLC controlled by: SIMENS (from Germany) or MITSUBISHI (from Japan);

5, Pneumatic parts adopt: AIRTAC (from Taiwan);

6, Filling nozzles with anti-leaking function;

7, Easy to operate, no bottle no filling, auto orientation detection;

8, Can equip with auto production line: bottle sorting, filling, cap feeding, capping, sealing, labeling, printing, packing and

etc.

9, Machine applied with Italy O-rings and mixing motor.

10, Adopting 180W mixing motor

11,Adopting Japan Omron heating controller

12, Filling set adopts preventing leaking and preventing silk nozzle

Product Paramenters

|

Name

|

Automatic 2 nozzles liquid filling machine

|

|

Model

|

VLF-2

|

|

Filling range

|

5-50ml,50-500ml,1000-5000ml

|

|

Stable capacity (BPH)

|

1200~1800BPH

|

|

Filling error

|

±1% (for the max filling range)

|

|

Voltage

|

380V/220V/110V,50-60Hz (or you required)

|

|

Power

|

800W

|

|

Air pressure:

|

0.4~0.6MPa

|

|

Air consumption

|

150L/min

|

|

Dimension

|

1500mm×800mm×1600mm

|

Detailed Images

Certifications

Packing&Shipping

Packing

The package adopts outside package (standard export wooden case) and inner package (stretch film), it is suitable for long distance transport, damp proofing, rust prevention, and shockproof etc, and also suitable for sea, land transport and entirety lifting.

After Sales Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* 24 hours Hotline: 86-13917505479 (English speaking engineer)

Semi-automatic liquid filling machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Pre-made pouch filling and sealing machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Pre-made pouch filling and sealing machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches